1

OPERATING

The lever is the on/off valve for the tool. Connect to a suitable

air supply and ensure the air pressure measured at the tool inlet

with the tool running does not exceed 90 PSIG (6.2 bar). Select

disc type and ensure that the disc is not cracked or damaged

and that the speed rating of the disc is in excess of 25,000

RPM. Using only the spacer (30) supplied with the tool, fit the

disc and tighten wheel screw (31) while holding nut (28). Do not

over tighten as this could crack the disc. Ensure wheel cover

(27) is in place. When first starting the tool with a new or changed

disc the tool should be first started in a protected area i.e. such

as under a heavy bench and run for a minimum time of one

minute. This will provide protection if the wheel should break

because a fault was not detected.

Always use eye protection and wear protective gloves. Remem-

ber that the cutting process will generate heat and that cut

parts, particularly small items, can get very hot and burn fingers

if touched. Allow cut parts to cool.

The tool and the work process may create a noise level such

that ear protectors should be worn. The cutting process will

create dust and the use of breathing masks is recommended.

Check that the material being cut will not cause harmful dust or

fumes. If this is so, then special breathing apparatus may be

required. Seek advice before starting work. The cutting process

will create sparks. Ensure that these do not create a hazard to

any person, object or process, and are not directed near any

flammable materials or fluids. Do not use the cutter in explosive

environments. Do not apply excessive loads to the tool as this

will reduce the efficiency of the disc. Apply light loads and allow

the wheel to cut. Try always to keep the disc square to the cut.

Do not apply side loads or grind on the side of the disc. Handle

the cutter with care. If the cutter is dropped, carefully examine

the disc for damage and replace if necessary. Start the tool as

for the first time of fitting a disc. i.e. under a bench. Make sure

that the object to be cut is in a firm, fixed position.

Printed In U.S.A.

Form ZCE577

Date 2003July23/C

Page 1 of 18

INSTRUCTIONS & PARTS LIST FOR 1957HP CUT-OFF TOOL

Read and understand "Safety Instructions For Air Tools" and these instructions before

operating this tool.

AIR SUPPLY

The efficiency of the tool is dependent on the proper supply of

clean dry air at 90 psig (6.2 bar). The use of a line filter, pres-

sure regulator, and lubricator will insure maximum output and

life of tools. Before connecting tool, blow out the air line to

remove water and dirt which may have accumulated.

HOSE AND HOSE CONNECTIONS

Supply hose should be not less than 3/8" (10mm) I.D. Exten-

sion hoses should be at least 1/2" (13mm) I.D. Use couplings

and fittings with at least 3/8" (10mm) I.D.

LUBRICATION

Use SIOUX No. 288 air motor oil. An airline lubricator, set to

deliver 2 to 3 drops per minute, is recommended. If a lubricator

is not used, add .08 oz. (2.4 cc, 24 to 30 drops) of oil into the

air inlet every 2 to 3 hours.

INSTRUCTIONS FOR CUT-OFF TOOLS

GENERAL OPERATION

• The tool is equipped with a lock-out type lever in order to

prevent accidental start-up.

• Speed of the tool may be adjusted by turning the speed

control, which is located under the lever.

• Never operate without guide in place.

• A wheel with any chips or cracks should be removed from

service and destroyed.

USE OF THE TOOL

This tool is designed to be used with flat reinforced resin 2 7/

8" diameter maximum discs having a speed rated above 25000

RPM. The bore size of the disc is 3/8".

The tool should not be used with any other type or rating of

abrasive disc or wheel. It must never be used with saw blades

or other cutting devices.

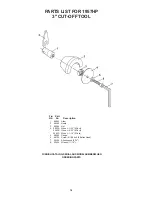

CHANGING WHEEL

1. Disconnect tool from air line.

2. Hold arbor stationary with an 11/16 (17.5 mm) wrench.

Remove screw retaining wheel with 3/16 (4.7 mm) allen

wrench.

3. Place new wheel on arbor, add flange with counterbore

towards wheel. Add screw and tighten.

Содержание 1957HP

Страница 17: ...17 NOTES ...