feature! The user cannot control the machine with vertical handle.

After switching on the machine, the handle will move shortly to the right.

Lifting or lowering the grip controls the direction, in which the machine moves.

The more you lift or lower the grip, the faster the machine runs to the

corresponding direction.

-

lifting the grip: machine runs to the right

-

lowering the grip: Machine runs to the left

If you feel unsafe or cannot control the machine just release lever (4). The

machine will stop at once. If you have carried out some training, you will be able

to operate the machine with one hand.

Always remove discs or brushes after work. Remove also the cleaning tank, if one

has been used. Always disconnect the power cord after work or when leaving the

machine.

Operation with vacuum cleaner

Note: the vacuum cleaner cannot – on technical grounds – remove the grinding

dust from under the discs. It will always remove the fine dust. To clean the floor,

use an industrial cylinder vacuum cleaner.

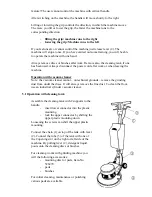

5.1 Operation with cleaning tank

Assemble the cleaning tank with 2 supports to the

handle.

5

-

insert lower connector into the plastic

mounting

-

lock the upper connector by shifting the

upper plastic mounting down

Loosening the screws can shift the upper plastic

mounting.

Connect the chain (1) on top of the tank with lever

(2). Connect the tube (3) of the tank with one of

the 2 openings (4) on the right or left side of the

machine. By pulling lever (2), detergent liquid

pours onto the cleaning discs or brushes.

For cleaning works with grinding machine you

will the following accessories:

-

mounting disc for pads, Item-No.

526270

-

pads

-

brushes

For initial cleaning, maintenance or polishing

various pads are available.

Содержание Surface Prep Machine 390

Страница 10: ...10 44 SP015510 Oil Seal Washer 45 SP015511 Washer 46 SP018219 Grub Screw M4 x 10 ...

Страница 11: ......

Страница 13: ...12 NOTES ...