User Manual

// Simpro MegaDumper®

Original Instructions // English // v86.0 // February 2022 // Page

40

4.9

Safety Door and Interlock System

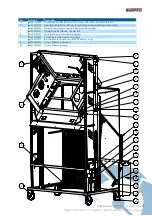

Swing-up safety door

Standard MegaDumper models are fitted with a swing-up safety door, consisting of a steel

tube frame with wire mesh or sheet-metal guarding, supported by two gas struts. This type of

door takes up a minimum of space, but has several moving parts and will benefit from

annual servicing as follows:

1.

Lubricate the arm pivot points with silicone spray (both ends of all four arms).

2.

Check both safety door interlocks

to ensure they work as intended:

a.

Raise the cradle 100mm off the ground and try to open the safety door. If it

can open, the cradle-position sensor and/or the door interlocks may need

adjusting or replacing. Contact your agent for instructions.

b.

Open the door, then press the RAISE and LOWER buttons to verify that the

machine is now disabled. If it is not, contact your agent for instructions.

3.

Ensure the end caps on the arm pivot bars are in place, and all fixings are tight.

4.

The gas struts are designed to balance the weight of the door throughout its travel,

and hold it open. Over time, the gas in the struts can leak out, resulting in reduced

lifting force. If the struts do not hold the door open, they may need to be replaced.

Idec interlocks

The MegaDumper is fitted with two solenoid-operated safety interlocks. These are Idec HS5E-

D4403-G or HS5E-F4403-G

‘ w

-to-

l ck’

models, with four internal contacts which are

used to determine whether the door is closed and locked.

4.9.2.1

Interlock manual override

This work should only be carried out by a

qualified technician.

The interlock Override Key should be

stored in a location only accessible to

supervisors and technical staff.

All routine cleaning and maintenance on the MegaDumper should be conducted with the

cradle in the lowered position. If for any reason the interior of the safety cage needs to be

accessed

while the cradle is raised

, the interlock(s) can be manually disabled by carrying

out the following procedure:

1.

Move the cradle to the desired position for cleaning or maintenance.

2.

Insert the supplied yellow Override Key into the triangular cam on

both

door

interlocks, and turn it to the UNLOCK position.

The door can now be opened even

while the cradle is raised.

-

On machines with a standard control system, the safety door will now function

as a switch

–

the cradle cannot be moved while the door is open, but can still

operate while the door is shut.

-

On machines with a PLd or PLe safety-monitored control system, the system

will enter SAFE MODE

–

the machine is completely disabled, and the cradle

cannot be moved until the door is closed, the interlock is re-enabled, and the

system is reset.

Содержание MegaDumper

Страница 1: ...User Manual Simpro MegaDumper Original Instructions English v86 0 February 2022 USER MANUAL...

Страница 3: ...User Manual Simpro MegaDumper Original Instructions English v86 0 February 2022 Page 2...

Страница 59: ...User Manual Simpro MegaDumper Original Instructions English v86 0 February 2022 Page 58 10 Notes...