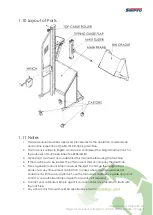

3.

Care and Maintenance

The Multi-Tip is designed to give many years of service with minimal maintenance. In the

event a fault or malfunction does occur, refer to the Quick Troubleshooting Guide in

before contacting your Simpro agent for support.

Contact your Simpro agent if repair or service work is required.

All repair and service work must be carried out by qualified personnel.

Replacement parts must be supplied by Simpro or an authorized Simpro agent, and must

be of the same design and specification as the original parts.

A detailed Service Manual giving specific testing and repair instructions is available on

request from Simpro.

3.1

Quick Troubleshooting Guide

Refer to the Quick Trouble Shooting Guide below before contacting your agent for service.

Problem

Possible Causes

Remedy

See also

Winch will not turn

Bin too heavy

Remove material from bin

to reduce the weight.

Winch turns but

cradle does not lift

Winch faulty or

broken

Repair or replace winch.

Lifting strap

broken

Replace lifting strap.

Cradle will not

come down from

the fully raised

position

Mast blocks

jamming in mast

Lightly lubricate inside of

mast with silicone spray.

Lubricate follower roller.

Winch faulty or

broken

Repair or replace winch.

Cradle jams part

way down

Mast bent or

damaged

Check and rectify; contact

your agent if necessary.

Tip guide flap

sticking or

damaged

Check and rectify; contact

your agent if necessary.

3.2

Cleaning

The machine may be cleaned with a low-pressure water jet, a microfiber cloth and a mild

cleaning solution. Cleaning should be carried out with the cradle in the fully-lowered position.

Do not clean the machine with a high-pressure water jet or waterblaster.

For IP ratings of the machine and various subcomponents see

Содержание Ezi-MT

Страница 1: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 USER MANUAL...

Страница 3: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 2...

Страница 29: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 28...

Страница 33: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 32...

Страница 34: ...9 Notes...

Страница 35: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 34...