User Manual

// Simpro Ezi-MT

Original Instructions // English // v40.0 // October 2022 // Page 16

3.3

Cradle jams

Occasionally the bin cradle may become jammed at some point in the tipping cycle. This is

usually a minor issue which can be easily rectified.

The cradle is not pulled or powered down

–

it is lowered by gravity alone.

Never place any part of your body underneath the raised cradle, unless it is securely

supported by a hoist, forklift, or other suitable arrangement.

3.3.1

Cradle jams while raising

If the cradle jams while being raised, the cause is usually due to the bin being too heavy, or

all the weight being at the bottom of the bin (rather than evenly distributed).

1.

Lower the cradle to ground level if possible.

2.

Remove some of the product manually, then try again.

3.

If the cradle jams even with a light bin or no bin at all, attempt to identify the cause,

and rectify with reference to the Service Manual (available on request from Simpro).

3.3.2

Cradle jams while lowering

If the cradle jams while lowering, or jams while raising but will not come down, the cause will

most likely be a mechanical fault. Use the following procedure to rectify the problem:

1.

Manually empty the bin if there is any product remaining in it.

2.

Attempt to identify the cause of the jamming. The most likely causes are:

a.

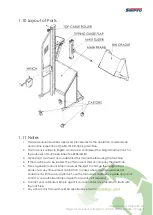

The tipping guide flap

may not be working correctly. When

lowering, a small pin on the cradle should lift the flap just before the follower

roller reaches the flap. If not, check that the pin has not been bent or broken.

b.

The shaft collar

holding the cradle onto the axle may have slipped,

allowing the follower roller

u f ‘ u ’ k

c.

The mast may have been bent or damaged, causing the mast blocks

d.

Lack of lubrication in the mast.

3.

Once the problem has been identified, rectify it, then lower the cradle to the ground.

4.

Raise and lower the cradle several times with no load to ensure the problem has

been properly resolved. Then also test with a full load.

5.

If there are no further problems, the machine may be returned to service.

3.4

Winch and strap

The Ezi-MT is fitted with a high-quality industrial braked winch and a black nylon lifting strap.

The winch uses an internal reduction gear arrangement, allowing the user to lift heavy bins.

The winch and lifting strap are suitable for outdoors use and require no regular maintenance.

If the winch is damaged or malfunctioning, or the lifting strap is visibly frayed, it should be

replaced. Contact your agent for a replacement strap.

Содержание Ezi-MT

Страница 1: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 USER MANUAL...

Страница 3: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 2...

Страница 29: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 28...

Страница 33: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 32...

Страница 34: ...9 Notes...

Страница 35: ...User Manual Simpro Ezi MT Original Instructions English v40 0 October 2022 Page 34...