2899

7

GB

4.3

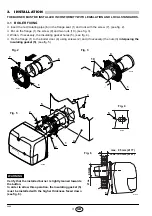

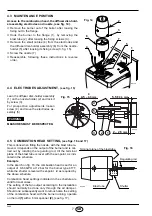

MAINTENANCE POSITION

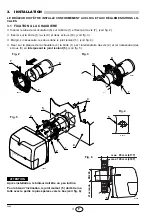

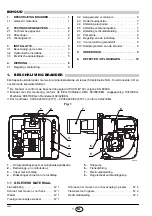

Access to the combustion head, the diffuser disc-hold-

er assembly, electrodes and nozzle, (see fig. 14).

➤

Remove the burner out of the boiler, after loosing the

fixing nut to the flange.

➤

Hook the burner to the flange (1), by removing the

blast tube (2) after loosing the fixing screws (3).

➤

Remove the small cables (4) from the electrodes and

the diffuser disc-holder assembly (6) from the nozzle-

holder (5) after loosing its fixing screw (3, fig. 15).

➤

Screw the nozzle (7).

➤

Reassemble, following these instructions in reverse

order.

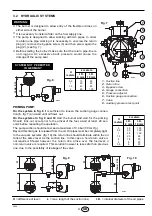

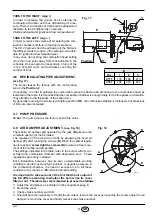

4.4

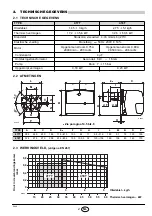

ELECTRODES ADJUSTMENT,

(see fig. 15)

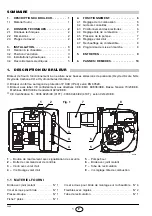

4.5

COMBUSTION HEAD SETTING,

(see figs. 16 and 17)

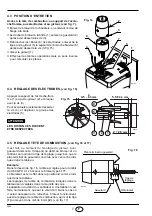

This is done when fitting the nozzle, with the blast tube re-

moved. It depends on the output of the burner and is car-

ried out by rotating the regulating rod, till the terminal

plane of the blast tube is level with the set-point, as indi-

cated in the schedule.

Example

In the sketch on fig. 16, the combustion head is set for an

output of 0.60 GPH at 12 bar for the burner type 417T,

while the shutter is level with set-point 2, as required by

the above schedule.

Combustion head settings indicated in the schedule are

valid for most cases.

The setting of the fan output according to the installation

should normally be done only through the air damper.

Should one subsequently want to retouch also the setting

of the combustion head, with the burner running, operate

on the rod (1) with a 6 mm spanner (2), (see fig. 17).

E9136

Fig. 14

2

3

5

1

6

4

7

MEASURES MUST BE RESPECTED.

WARNING

D6049

4

5

3

1

4.5

– 0.5 mm

0

2

–

2.5

mm

5.5 ±

0.3 mm

2

Fig. 15

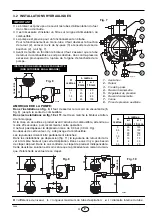

Lean the diffuser disc-holder assembly

(1) on the nozzle-holder (2) and lock it

by screw (3).

For prospective adjustments loosen

screw (4) and move the electrodes as-

sembly (5).

3

5

6

4

2

0

3

D5589

Blast tube

Shutter

Terminal plane of the blast tube

Regulating rod

Fig. 16