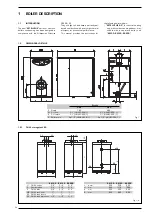

3.1

COMMISSIONING THE BOILER

When commissioning the boiler always

make sure that:

– the system has been filled with water and

adequately vented;

– the flow and return valves are fully open;

– the flue and chimney are free from

obstructions;

– the electrical connections to the mains

and the earthing are correct;

– no flammable liquids or materials are

near the boiler;

– check that the circulating pump is not

locked.

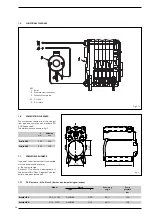

3.2

LIGHTING AND OPERATION

3.2.1

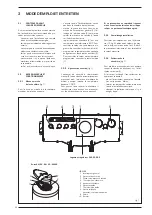

Lighting the boiler

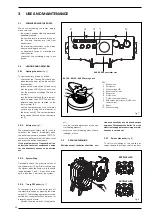

(fig. 7)

To light the boiler proceed as follows:

– check that the “Testing Certificate” has

been removed from inside the combus-

tion chamber;

– switch on the main switch (1) and verify

that the green LED (3) turns on to con-

firm the presence of voltage.The burner

will start;

– turn the boiler stat knob (5) to a temper-

ature no lower than 60°C. The set tem-

perature value can be checked on the

thermometer (4).

– set the temperature of the hot-water

service by pressing the thermostat of

the boiler unit (6). The set temperature

value can be checked on the thermome-

ter (7).

3.2.2

Safety stat

(fig. 7)

The manually reset safety stat (2) trips to

switch-off the burners immediately when

the boiler temperature exceeds 100°C. To

restart the boiler, unscrew the black cover

and press the button underneath.

If the problem occurs frequently, call an

authorised technical assistance centre

for the necessary checks to be carried

out.

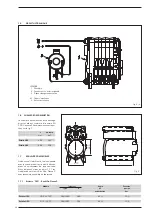

3.2.3

System filling

Periodically check the pressure values of

the hydrometer (13 fig. 2/a) mounted onto

the system, when the system is cold, should

range between 1 and 1.2 bar. If the pres-

sure is less than 1 bar, reset the system.

3.2.4

Turnig OFF boiler

(fig. 7)

To temporarily turn off the boiler turn off

the electricity supply by pressing the main

switch (1). The following operations must be

carried out if the plant will not be in use for

a lengthy period of time:

– position the main switch of the plant on

off;

– turn the fuel and water taps of the cen-

tral heating plant off;

– empty the central heating plant if there

is danger of frost:

3.3

REGULAR CLEANING

Maintenance of the boiler should be car-

ried out annually by an authorised service

engineer. Disconnect the boiler from the

electrical supply before servicing or main-

tenance is carried out.

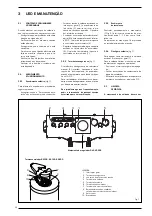

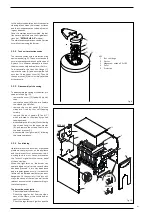

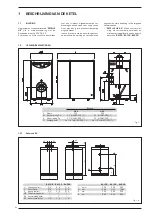

3.3.1

Smoke side boiler

(fig. 8)

To carry out cleaning of the smoke pas-

sages remove the screws that fix the door

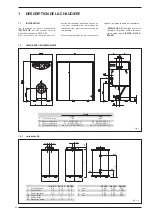

RONDO' 3/4 OF

ESTELLE 3/4 OF

RONDO' 5/6 OF

ESTELLE 5/6 OF

40

1

2

4

5

3

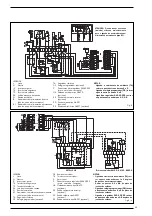

Fig. 7

KEY

1

Main switch

2

Safety stat

3

Green voltage LED

4

Boiler thermometer

5

Boiler stat

6

D.H.W. stat

7

D.H.W. tank thermometer

8

Bulb holder thermostat/D.H.W. tank

thermometer

9

Relais

10

Connector plug

BA100 - BA150 - BA200 storage tank

10

6

8

7

9

3

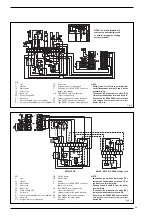

USE AND MAINTENANCE

Fig. 8

ESTELLE HE 4

ESTELLE HE 5

RVA 43.222 controller slot

Содержание ESTELLE HE

Страница 1: ...IT ES ENG FR SL BE GR DE PT RO RUS Estelle HE CERTIFICAZIONE DEL SISTEMA DI QUALITA AZIENDALE ...

Страница 116: ......

Страница 118: ......

Страница 119: ......