away from any electrical components.

The connections to the expansion relief

valve and temperature and pressure relief

valve should not be used for any other pur-

pose.

See fig. 6 for example of the discharge

pipe(s) for the temperature and pressure

relief valve, and expansion relief valve termi-

nations. Note: it is permitted to connect

discharge pipes together provided that the

joint pipe is sized to accommodate the

combined flow.

2.4.4 Expansion Vessel (C.H. only)

C.H. EXPANSION VESSEL – The integral

expansion vessel is pre-charged to a pres-

sure of 1.0 bar, which should be checked

before the C.H. water system is filled.

This vessel is suitable for correct operation

of system capacities up to 82 litre capacity.

If the actual C.H. system volume is greater,

then an additional vessel must be fitted to

the system. For systems where the volume

is greater, the additional expansion vessel

volume can be determined by multiplying

the volume in excess of that which can be

accommodated by the appliance by the fac-

tor 0.901. BS 7074 gives further details

regarding C.H. expansion vessel sizing.

2.4.5

Connection of condensation

water trap

The drip board and its water trap must be

connected to a civil drain through a pipe

– If the terminal discharges into a pathway or passageway check

that combustion products will not cause nuisance and that the ter-

minal will not obstruct the passageway.

– Where the lowest part of the terminal is fitted less than 2 m (78

in) above ground, above a balcony or above a flat roof to which peo-

ple have access, the terminal MUST be protected by a purpose

designed guard. Terminal guards are available from Quinnell,

Barrett, and Quinnell, Old Kent Road, London. State model C2,

(G.C. Part No 382946).

– Where the terminal is fitted within 850 mm (34 in) of a plastic or

painted gutter, or 450 mm (18 in) of painted eaves, an aluminium

shield at least 1,500 mm (59 in) long must be fitted to the under-

side of the painted surface.

– The air inlet/outlet flue duct MUST NOT be closer than 25 mm (1

in) to combustible material.

– In certain weather conditions the terminal may emit a plume of

steam. This is normal but positions where this would cause a nui-

sance should be avoided.

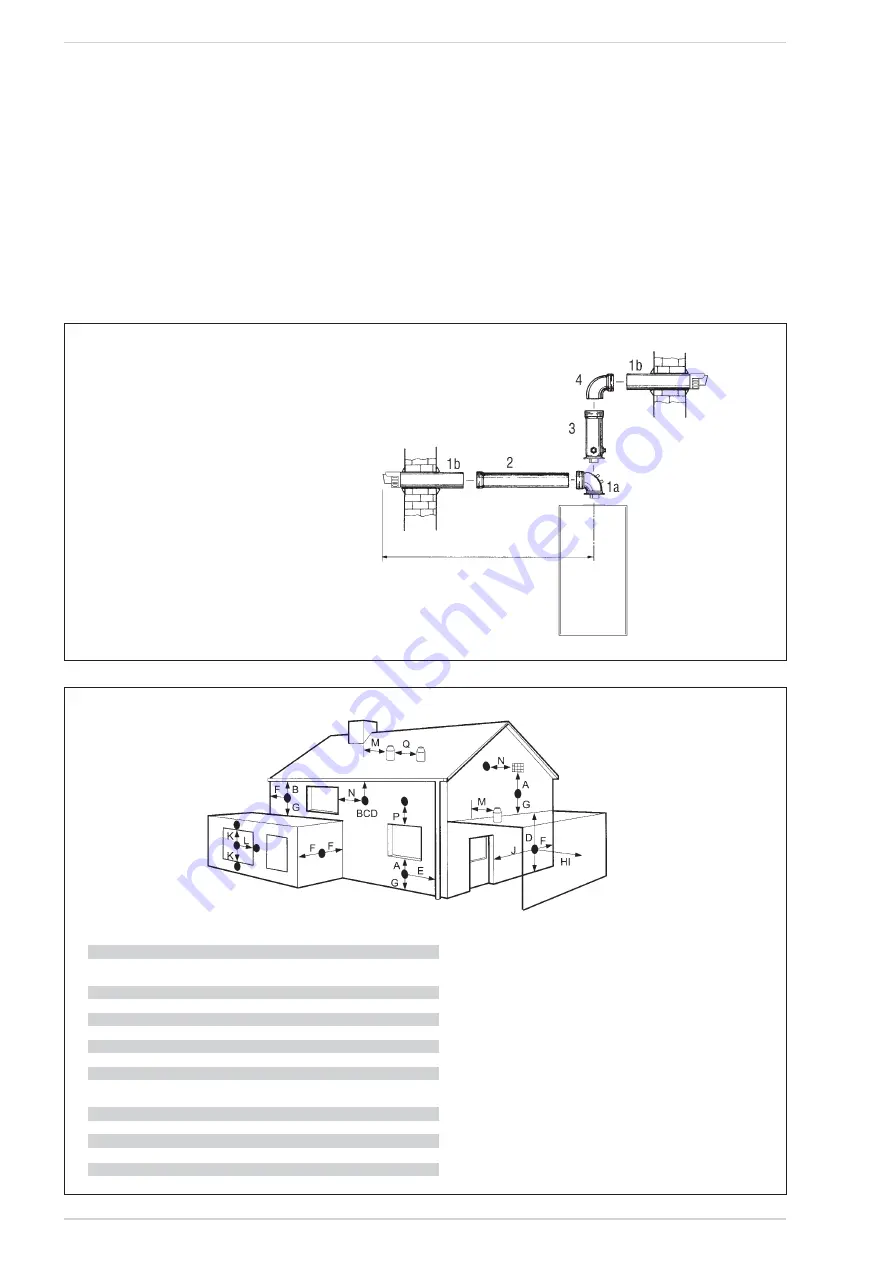

Fig. 8

Terminal position

Minimum spacing

A

Directly below an openable window, air vent

or any other ventilation opening

300 mm 12 in

B

Below guttering, drain pipes or soil pipes

75 mm

3 in

C/D

Below eaves, balconies or carport roof

200 mm

8 in

E

From vertical drain pipes or soil pipes

75 mm

3 in

F

From internal or external corners

300 mm 12 in

G

Above adjacent ground, roof or balcony level

300 mm 12 in

H

From a surface facing the terminal

600 mm 24 in

I

From a terminal facing the terminal

1,200 mm 48 in

J

From an opening in the carport

(eg door, window into dwelling)

1,200 mm 48 in

K

Vertically from a terminal on the same wall

1,500 mm 60 in

L

Horizontally from a terminal on the same wall

300 mm 12 in

M

Horizontally from a vertical terminal to a wall

300 mm 12 in

N

Horizontally from an openable window or other opening 300 mm 12 in

P

Above an openable window or other opening

300 mm 12 in

TABLE 1

Fig. 7

IMPORTANT:

Each additional 90° curve installed reduces

the available length by 0.90 metres.

Each additional 45° curve installed reduces

the available length by 0.45 metres.

max 4,6 m

KEY

1a-b Coaxial duct kit code 8096250

2a

Extension L. 1000 code 8096150

2b

Extension L. 500 code 8096151

3

Vertical extension L. 140 with take-off point code 8086950

4a

90° additional bend code 8095850

4b

45° additional bend code 8095950

NOTE: Before installing accessories, lubricate the internal part of

gaskets with silicon-based products. Avoid using oils and greases.

NOTE: Place the duct horizontally.

11