24

0

30

20

10

∆

p aria mm H

2

O

P

o

tenza t

e

rmica kW

25

20

10

15

50

40

60

5

30

50-30

°

C

35

70

80-60

°

C

0

30

20

10

∆

p aria mm H

2

O

P

o

tenza t

e

rmica kW

25

20

10

15

50

40

60

5

30

50-30

°

C

35

70

80-60

°

C

G20

G31

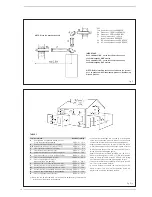

4.3.1

Diagram illustrating heat output in relation to “air

∆

p”

TABLE 4/a - G20

* Air

∆

p is measured during boiler operation using a differential pressure gauge connected to the ventilator intake.

** The gas consumptions refer to the calorific value at standard conditions at 15°C - 1013 mbar.

Variable heat output

Air

∆

p*

Gas consum.**

(80-60°C) (50-30°C)

(80-60°C) (50-30°C)

G20

kW

kW

mm H

2

O

mm H

2

O

m

3

/h st

29,3

32,0

63,8

66,4

3,17

22,9

25,0

45,0

45,0

2,48

16,1

17,6

25,0

25,0

1,75

10,4

11,4

8,4

9,2

1,14

TABLE 4/b - G31

Variable heat output

Air

∆

p*

Gas consum.**

(80-60°C) (50-30°C)

(80-60°C) (50-30°C)

G31

kW

kW

mm H

2

O

mm H

2

O

kg/h

29,3

32,0

68,4

70,4

1,52

21,8

23,4

45,0

45,0

1,19

15,4

16,6

25,0

25,0

0,84

10,4

11,4

9,2

9,5

0,55

Fig. 22

Heat out

out (kW)

Air

∆

p mm H

2

O

Heat out

out (kW)

∆

p de aire mm H

2

O

4.4

COMMISSIONING

The gas valve is factory set and should

require no adjustment.

PLEASE NOTE: The combustion for this

appliance has been checked, adjusted and

preset at the factory for operation on the

gas type specified on the appliance data

plate. However it is advisable to check for

correct combustion having first checked:

– That the boiler has been installed in

accordance with these instructions.

– The integrity of the flue system and the

flue seals

– The integrity of the boiler combustion cir-

cuit and the relevant seals.

Proceed to put the boiler into operation as

follows, after installation a gas purge and

tightness/drop test have been made.

Ensure that the pump has been manually

rotated. Switch the boiler to the SUMMER

position. Open the gas cock, Ensure that any

timers or room thermostats are in the on

position.

The boiler will attempt to light.

4.5

CHECK THE OPERATIONAL

(WORKING) GAS INLET PRESSURE

Set up the boiler to operate at maximum

rate condition (chimney sweep) as

described in 4.6.2.

With the boiler operating in the maximum

rate condition, check that the operational

(working) gas pressure at the inlet test

point (see fig. 20 item 3), complies with the

requirements of 1.3.

Ensure that this inlet pressure can be main-

tained with all other appliances in the prop-

erty working.

4.5.1

Combustion Check

Competence to carry out the check of the

combustion performance.

PLEASE NOTE: BS 6798: 2009 Specification

for installation and maintenance of gas-fired

boilers of rated input not exceeding 70 kw

net advises that:

– The person carrying out a combustion

measurement should have been

assessed as competent in the use of a

flue gas analyser and the interpretation

of the results;

– The flue gas analyser should be one

meeting the requirements of BS7927 or

BS-EN50379-3 and be calibrated in

accordance with the analyser manufac-

turers requirements, and competence

can be demonstrated by satisfactory

completion of the CPA1 ACS assessment

which covers the use of electronic

portable combustion gas analysers in

accordance with BS7967, parts 1 to 4.

Connect the flue gas analyser to the flue

gas sampling point as shown in fig 23 and

check the combustion following the

sequence described in 4.4.

CO / CO

2

RATIO

Fig. 23

CO ppm

1

00

400

CO

2

%

NG 9%

0,0011

0,0044

LPG 10%

0,0010

0,0040

Содержание Dewy 130 HE FS

Страница 3: ......

Страница 32: ...32 5 EXPLODED VIEWS COD TYPE DATE PAGE 3810009 505 DEWY 30 130 HE FS 31 10 2007 1 6 ...

Страница 33: ...COD TYPE DATE PAGE 3810009 505 DEWY 30 130 HE FS 31 10 2007 2 6 33 ...

Страница 34: ...34 COD TYPE DATE PAGE 3810009 505 DEWY 30 130 HE FS 31 10 2007 3 6 ...

Страница 39: ......