12

– It is important to check the inhibitor

concentration after installation, system

modification and at every service in

accordance with the manufacturer’s

instructions (Test kits are available from

inhibitor stockists).

FLUES INSTALLATION MUST COMPLY

WITH THE CURRENT VERSION OF

BS5440.

2.5

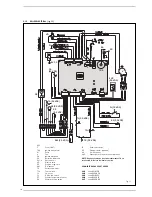

INSTALLATION COAXIAL DUCT

ø 60/100 - ø 80/125 (fig. 6)

The coaxial suction and discharge pipes are

supplied in a special kit (that can be purcha-

sed separ at el y) along wit h assembl y

instructions.

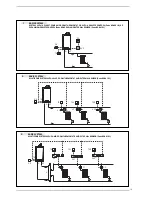

The diagrams of fig. 6 illustrate some

examples of different types of fluing options

allowed and the maximum lengths that can

be reached.

2.6

INSTALLATION OF SEPARATE

DUCTS ø 80 (fig. 7)

The kit with dedicated pipes enables to

separate the exhaust fumes pipes from the

air suction pipes (fig. 7):

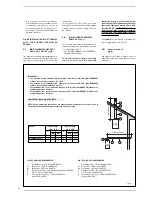

– for ø 80 pipes, adaptor code 8093050 is

available upon request.

The maximum overall length, resulting

fr om the sum of all the suction and

discharge pipes, is determined by the

load losses of the single connected acces-

sories and should not exceed 15 mm H

2

O

(version 25-30) (ATTENTION: the total

length of each pipe should not exceed 50

m, even if the total loss is below the maxi-

mum applicable loss.)

See

Table 3

for information on the load los-

ses of single accessories (fig. 8).

2.6.1

Separate ducts kit

(fig. 8)

The diagrams of Figure 8 show a some of

examples of the permitted exhausts confi-

gurations.

C33

6

5

3

2

C43

3

4

2

x

y

x + y = L (m)

H (m)

C13

1

2

1

L (m)

2

LIST OF ø 60/100 ACCESSORIES

1

Coaxial duct kit L. 790 code

8096250

2a

Extension L. 1000 code

8096150

2b

Extension

L. 500 code 8096151

3

Vertical extension

L. 140

with coupling code

8086950

5

Tile for joint code

8091300

6

Terminal for roof exit L.

1285 code 8091212

(includes 8086950)

Model

Length of pipe

Length of pipe

ø 60/100

ø 80/125

H

V

H

V

Min

Max

Min

Max

MERIDIAN HE 30 C

5 m

1.3 m

7 m

10 m

1.2 m

13 m

LIST OF ø 80/125 ACCESSORIES

1

Coaxial duct kit L. 785 code

8096253

2a

Extension

L. 1000 code 8096171

2b

Extension

L. 500 code 8096170

3

Adapter for

ø 80/125 code 8093150

5

Tile for joint code

8091300

6

Terminal for roof exit L.

1285 code 8091212A

(includes 8093150)

H (Horizontal) m

V (V

er

tical) m

IMPORTANT:

– The insertion of each additional 90° bend with a diameter of 60/100 (code 8095850)

reduces the available section by 1.5 meters.

– The insertion of each additional 90° bend with a diameter of 80/125 (code 8095870)

reduces the available section by 2 meters.

– Each additional 45° curve installed a diameter of 60/100 (code 8095550) reduces the

available length by 1.0 metres.

– Each additional 45° curve installed a diameter of 80/125 (code 8095970) reduces the

available length by 1.0 metres.

HORIZONTAL FLUES MUST BE LEVEL

NOTE: Before connecting accessories, it is always advisable to lubricate the internal part of

the gaskets with silicon products. Avoid using oils and greases.

Fig. 6