- 18 -

Boiler overheating temperature [A 99] - value, exceeding which causes

permanent turn off of the fan to prevent boiler overheating. After the

temperature increases above 80

˚

C the central heating pump is turned on to cool

down the boiler. Overheating mode is shown by indicating error [E 2] on the

display. It can be turned off by pressing STOP button, but only when

temperature decreases below this temperature.

Fan turn off also occurs in case of damage of the boiler temperature sensor

which is shown on the display with error [E 1].

STB

- the controller has additional protection against overheating which is

independent from the processor. In case the temperature increases over 95°C,

the control process is turned off by turning the fan off and launching the central

heating pump. The fan and the pump are turned on to the control process again

when temperature drops below 89°C.

STB circuit enables more precise boiler work control and reduces overheating

possibility.

(6) No

fuel

No-fuel testing time during fuel firing start [Fd60] - after switching to WORK

mode, if water temperature does not increase by 5°C in programmed time, the

control process will be turned off and the display will show the message:

[FUEL].

You can return to previous mode by pressing STOP button. No fuel testing time

during fuel firing is finished after the set temperature is achieved.

No-fuel testing time during work mode [Fb30] - in WORK mode, if temperature

of water in the boiler decreases below temperature set with the thermostat, by

hysteresis value, and does not increase by 5°C in the programmed time, the

control process will be turned off and the display will show the message:

[FUEL].

You can cancel the alarm by pressing STOP button.

(7) Additional

output

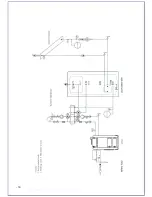

Additional output [Ar 0] – the controller has been equipped with an output that

allows connection of the UM module. When the Ar parameter has the UM

module value “0” it may control the oil or gas boiler – if such boiler exists in the

heating circuit. After switching the controller with the main power switch the

additional boiler is turned off and it turns on again when there is no fuel in the

solid fuel boiler. This function is useful in heating systems where there is a solid

fuel boiler used to cut the heating costs. After erasing the “no fuel” alarm by

pressing STOP button the additional boiler is again turned off and the controller

works again. Setting parameter [Ar] to “1” allows controlling the additional alarm

signaling system with the UM module – which occurs on the controller.

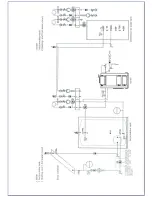

When Ar parameter is set to “2” the UM module allows controlling the mixing

valve servo-motor in the central heating circuit depending on the room

thermostat input. In this case the work of central heating pump depends only on

the boiler temperature.

Содержание Holzgas

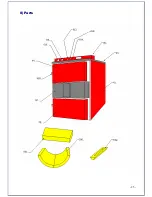

Страница 25: ... 25 8 Parts ...

Страница 28: ... 28 ...

Страница 30: ... 30 ...

Страница 31: ... 31 ...

Страница 32: ... 32 ...