4/8

Siemens Building Technologies

Electrical Actuators

CA1N4895en

HVAC Products

08.03.2004

Notes

The actuators must be electrically connected in accordance with local regulations (refer

to «Connection diagrams»).

Regulations and requirements to ensure the safety of people and property must

be observed at all times!

The permissible temperatures must be observed (refer to «Technical data»).

Mounting Instructions 74 319 0260 0 are enclosed with each pack.

Assembly is made with the coupling nut; no tools or adjustments are required. The

actuators should be installed so that they are initially in position 0 (also refer to

«Operation»).

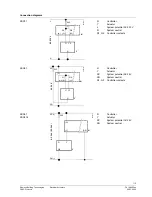

90°

90°

48

99

Z03

When commissioning the system, check wiring and the functions of the actuator.

Before testing the functioning of the SSC..., always check to ensure that the

actuator concerned is mounted on a valve (refer to «Equipment combinations»).

Calibrating the SSC61 or SSC61.5 without a valve connected causes the actuator to

lock in position 1. To recalibrate (after mounting on a valve), disconnect power and

reset the stroke manually from position 1 to 0 (refer to «Recalibration»).

The rotary knob can be used to drive the actuator into any position between 0 and 1.

However, if a control signal from the controller is present, this will take priority in

determining the position.

To retain the manually set position, unplug the connecting cable. Due to the reset

function, the SSC61.5 will first travel to position 0 and can then be driven manually to the

required position.

B

A

B

(Y2)

(Y, Y1)

A

48

9

5Z04

A

4895

Z

0

5

0

1

Position indicator in

position 1 = OPEN

B

489

5Z

06

0

1

Position indicator in

position 0 = CLOSED

Engineering

Caution

Mounting

Orientation

Commissioning

Caution

Operation

Note