SIRIUS

Safety Relay

3TK2841

DIN EN 60 947-5-1 (08.00)

Operating Instructions

Order No.: 3ZX1012-0TK28-1JA1

English

2

Read and understand these instructions before installing, operating, or

maintaining the equipment.

Reliable functioning of the equipment is only ensured with certified

components.

The safety switching device must be installed in switchgear cubicles

complying with degree of protection IP32, IP43 or IP54, depending on the

prevailing environmental conditions.

The products described herein are designed to be components of a customized

machinery safety-oriented control system. A complete safety-oriented system

may include safety sensors, evaluators, actuators and signaling components. It

is the responsibility of each company to conduct its own evalution of the effec-

tiveness of the safety system by trained individuals. Siemens AG, its subsidia-

ries and affiliates (collectively "Siemens") are not in a position to evaluate all of

the characteristics of a given system or product or machine not designed by

SIEMENS.

Siemens accepts no liability for any recommendation that may be implied or sta-

ted herein. The warranty contained in the contract of sale by Siemens is the sole

warranty of Siemens. Any statements contained herein do not create new war-

ranties or modify existing ones.

The 3TK2841 safety relay can be used in EMERGENCY STOP devices according

to EN 418 and in safety circuits according to EN 60 204-1 (11.98), e.g. in

movable guards and protective doors or in non-contact protective devices in

accordance with IEC 61496-1 (06.98), electrical equipment for furnaces in accor-

dance with DIN VDE 0116 (10.98) and automatic firing systems for gas burners

in accordance with DIN EN 298 (02.94). Depending on the external circuit ele-

ments, safety category 4 according to DIN EN 954-1 or SIL 3 according to

IEC 61508 can be achieved.

The 3TK2841 safety relay has two reliable solid-state outputs. Three LEDs indi-

cate the operating state and the function.

When the device is put into operation it runs through a self-test to test the

correct functioning of the internal electronics. All internal circuit components

are monitored for faults cyclically during operation.

Connect the EMERGENCY STOP button and/or the position switches or light

arrays to terminals Y11, Y12 and Y21, Y22. Connect the ON button in series with

the NC contacts of the external actuators to the supply voltage L+ (24 V DC) and

to terminal Y34. Connect cascading input 1 either via a safe output or directly to

the supply voltage L+ (24 V DC).

External actuators or loads can be switched via safe outputs 14, 24. It must be

ensured that the actuators or loads and the 3TK2841 electronic safety relay have

the same frame potential. Paralleling outputs 14 and 24 to increase the load cur-

rent is not permissible.

If electronic sensors (light-array monitoring, etc.) are used, and in single-channel

operation, Y35 must be connected to L+ (24 V DC). For autostart operation, Y32

must be connected directly to L+ (24 V DC) and Y34 must be connected to it via

NC contacts of the external actuators.

Use a power pack to IEC 60536 safety class III (SELV or PELV)

for power supply!

1)

Sensor circuits open; Cross-circuit between the sensors; Short-circuit of sensors

to frame

2)

only when using circuit variant with "cross-circuit detection"

3)

Safe outputs disconnected for test purposes; sufficiently slow actuators are

not affected.

For further data and accessories see Catalog.

DANGER

Hazardous voltage.

Will cause death or serious injury.

Disconnect power before working

on equipment.

IMPORTANT NOTICE

Application

Functional description and instructions for connection

Terminal

assignments

Operating

voltage

A1

A2

L+

M

Sensors Y11, Y12

Y21, Y22

Y35

Y32

Y34

Channel 1 EMERGENCY STOP or position switch

Channel 2 EMERGENCY STOP or position switch

With / without cross-circuit detection

Autostart changeover switch

ON button, feedback circuit

Input

1

Cascading input

Outputs 14, 24

Safe Solid-state outputs

Cable lengths

for 2 x 1.5 mm

2

max. 2000 m (total cable length for sensors)

!

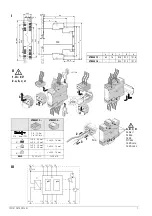

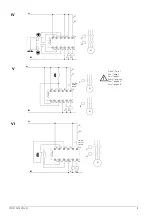

Figures

Fig. I:

Fig. II:

Fig. III:

Fig. IV:

Fig. V:

Fig. VI:

Fig. VII:

Fig. VIII:

Fig. IX:

Dimension drawings (dimensions in mm)

Installation/Connection

Internal circuit:

¿

power pack,

À

control logic,

Á

Output 1,

Â

Output 2

Protective-door monitoring, two-channel, autostart category 4 to EN 954-1

EMERGENCY STOP, single-channel, monitored start category 2 to EN 954-1*

EMERGENCY STOP, two-channel, monitored start, category 4 to EN 954-1

Light-array monitoring, two-channel, autostart category 4 to EN 954-1

EMERGENCY STOP, two-channel, monitored start and protective-door

monitoring, autostart category 4 to EN 954-1

Safety mat, two-channel, autostart category 3 to EN 954-1

*) This wiring example only satisfies category 2 according to EN 954-1 if a warning is

automatically generated when the actuator fails or the machine control initiates a safe state.

Otherwise an alternative shut-down method is required.

Operating states

LEDs

Operation

POWER RUN

FAULT

PS

EMERGENCY

STOP

ON button

Outputs

ON

not activated activated

on

activated

1)

not activated off

not activated not activated off

flashes

on startup self-test approx. 7 sec.

Faults

flashes

• Defect in electronics

• Change in terminal assignment

during operation

• Short-circuit to 24V

2)

off

No supply voltage

Technical data

Permissible ambient temperature T

u

Operation/storage

–25 to +60 °C/–40 to +80 °C

Degree of protection to EN 60 529

IP40, IP20 at terminals

Rated insulation voltage

50 V

Rated impulse withstand voltage

500 V

Rated control supply voltage

24 V DC

Rated power

1.3 W

Operating range

0.9 to 1.15 x U

s

Shock resistance (half-sine) as per IEC 60068

8

g

/10 ms

Weight

150 g

Recovery time after EMERGENCY STOP

min. 200 ms

Recovery time after power failure

7 s

Release time after EMERGENCY STOP

30 ms

Pickup time

max. 40 ms

Short-circuit protection

no fusing necessary!

Dark time

3)

<

1 ms

Start signal Y34

pulse (min.200 ms / max. 5 s)

Utilization category

as per IEC 60947-5-1

Rated operational vol-

tage

Rated operational current

per output

DC-13

24 V

2.0 A