8

Installation

Pipe dimensions

Note:

The device manufacturer does not assume any warranty

for complaints attributable to the pipe section.

■

The device achieves its optimum performance by means of a

short, straight exhaust air pipe and as large a pipe diameter

as possible.

■

Because of long rough exhaust air pipes, many of which are

pipe bends or have diameters smaller than 150 mm, the

optimum extraction performance is not achieved and fan

noise is increased.

■

The pipes or hoses for laying the exhaust air line must

consist of non-combustible material.

Round pipes

An inner diameter of 150 mm, but at least 120 mm, is

recommended.

Flat ducts

The inner cross-section must correspond to the diameter of the

round pipes.

Ø 150 mm approx. 177 cm

2

Ø 120 mm approx. 113 cm

2

■

Flat ducts should have no sharp deflections.

■

Use sealing strip for deviating pipe diameters.

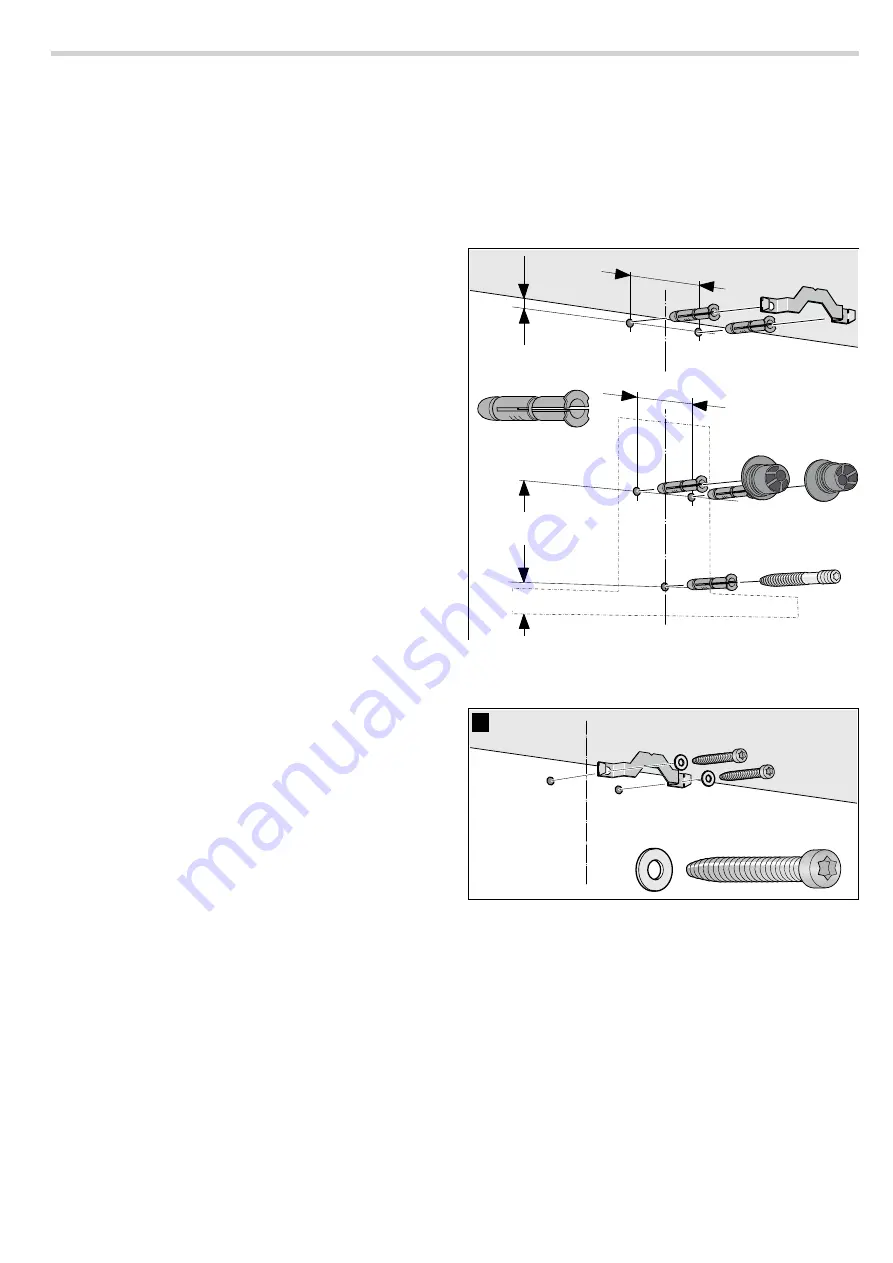

Checking the wall

■

The wall must be level, vertical and adequately load-bearing.

■

The depth of the bore holes must be the same length as the

screws. The wall plugs must have a secure grip.

■

The enclosed screws and wall plugs are suitable for solid

brickwork. Suitable fasteners must be used for other

structures (e.g. plasterboard, porous concrete, poroton

bricks).

■

The max. weight of the extractor hood is

40 kg

.

Preparing for installation

1.

Mark a vertical centre line on the wall from the ceiling to the

lower edge of the extractor hood.

2.

Mark the positions for the screws and the contour of the

attachment area.

3.

Drill five 8 mm Ø holes to a depth of 80 mm for the

attachments and press in the wall plugs flush with the wall.

Installation

1.

Screw on the fixing bracket for the flue duct.

¨

2.

Screw on brackets for the extractor hood hand-tight, max.

3 Nm

.

©

[

PP

PP

PP

PP

PP

[

$