Maintenance

Refer to Circuit Breaker Operator Manual.

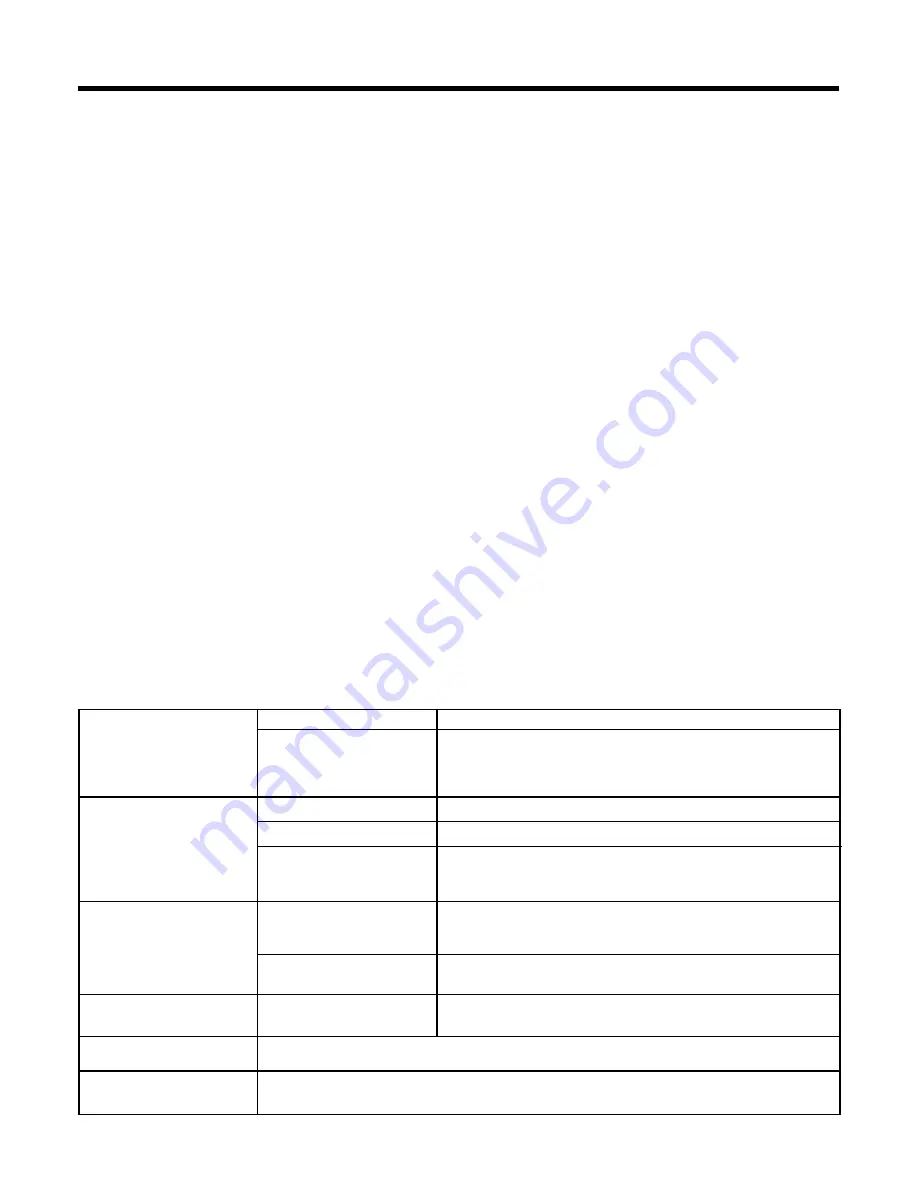

Table 2. Periodic Maintenance and Lubrication Tasks

Sub-Assembly

Item

Inspect For

Primary Power Path

Primary Disconnects

1. Burnt or damaged fingers

2. Lubrication of contact surfaces.

3. Tightness of nuts and other locking devices

Electrical Controls

Wiring

1. Mechanical damage or abrasion

Terminals and Connectors

1. Tightness and absence of mechanical damage

Close and Trip Solenoids, Anti-

Pump Relay, Auxiliary Switches,

Secondary Disconnect

1. Automatic charging

2. Close and trip with control power

High Potential Test

Primary Circuit to Ground

and between Primary Dis-

connects

1. 60 second withstand, refer to Circuit Breaker Operator Manual

SGIM-9928 for ratings.

Control Circuit to Ground

1. 60 second withstand, refer to Circuit Breaker Operator Manual

SGIM-9928 for ratings.

Insulation

Barriers and all Insulating

Components

1. Cleanliness

2. Cracking, crazing, tracking, or other sign of deterioration

Interrupter Operator

Mechanism

Always re-install the phase barriers carefully to the original

location prior to inserting the circuit breaker in the housing.

When the contacts are mated with the switchgear’s pri-

mary stud assembly, there is forceful contact distributed

over a wide area. This maintains low current flow per in-

dividual contact finger.

Inspect the contact fingers for any evidence of burning or

pitting that would indicate weakness of the contact finger

springs.

Inspect the primary disconnect arms for physical integrity

and absence of mechanical damage.

Inspect the flexible connectors that connect the bottom

movable contacts of the vacuum interrupters to the lower

primary disconnect arms for tightness and absence of

mechanical damage, burning, or pitting.

Using a clean cloth saturated with denatured alcohol, clean

old lubricant from primary disconnects, and apply Siemens

contact lubricant (reference 15-171-370-002) in a very thin

layer.

Fastener Check

Inspect all fasteners for tightness. Both lock-nuts and re-

taining rings are used. Replace any fasteners that appear

to have been frequently removed and replaced.

Racking Mechanism

Racking mechanism is to be wiped clean, and a film of

Anderol 732 aerosol synthetic fluid grease (reference part

number 15-172-816-058) applied on the shaft surfaces,

threads and nuts.

Electrical Control Checks

Check of the Wiring and Terminals

1. Physically check all of the switchgear wiring for evidence

of abrasion, cuts, burning or mechanical damage.

2. Check all terminals to be certain they are solidly attached

to their respective device.

Electrical Close and Trip Check (Control Power Required)

A check of the breaker control circuits is performed while

the unit is still connected to the switchgear by the plug

jumper. This check is made with the breaker energized by

control power from the switchgear.

1. Once the breaker springs are charged, move the

switchgear Close/Trip switch to the Close position. There

should be both the sound of the breaker closing and

indication that the breaker contacts are closed by the

main contact status indicator.

2. As soon as the breaker has closed, the automatic spring

charging process is repeated.

3. After a satisfactory close operation is verified, move the

switchgear Close/Trip switch to the Trip position. Verify

by both sound and contact position that the contacts

are open. Completion of these checks demonstrates

satisfactory operation of auxiliary switches, internal re-

lays and solenoids.

Checks of the Spring Charging Motors of the spring charg-

ing motor are necessary.

9

1.Cleanliness

2.Lubrification of shaft surfaces.

Racking Mechanism