23

5.

Maintenance

Danger

Precautions for Safe Working

service to test position.

Control terminals in the LV compartment must not be

5.1

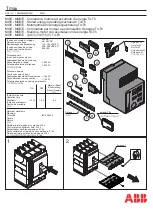

Switching Device Compartment

5.1.1

Inspection Schedule

position.

connections.

joints.

Before removing the front plate of the breaker operating

the instructions given on the mechanism housing.

Service the

switchgear at shorter intervals if the air is very moist

or full of dust or is otherwise polluted.

5.1.2

Cleaning

Caution

For Safety

Cleaning Agents

into contact with them.

clean cloth.

5.1.3

Lubrication

with neutral grease.

make

temperature up to 15

0

C.

Содержание 8BK80

Страница 8: ......