Operation (Continued)

b. A flush must be provided for

fluids with a viscosity of greater

than 2000 SSU. The seal must be

cooled and lubricated by a fluid.

In the case of high viscosity fluids,

due to the precision clearances

between the gear teeth and the

body, highly viscous fluids will not

be able to adequately relieve the

air in the seal cavity on start-up.

The dry running of a mechanical

seal will cause rapid failure.

Pumping fluids with

viscosities greater than

2000 SSU requires flushing the seal chamber

during operation, otherwise seal damage

will occur.

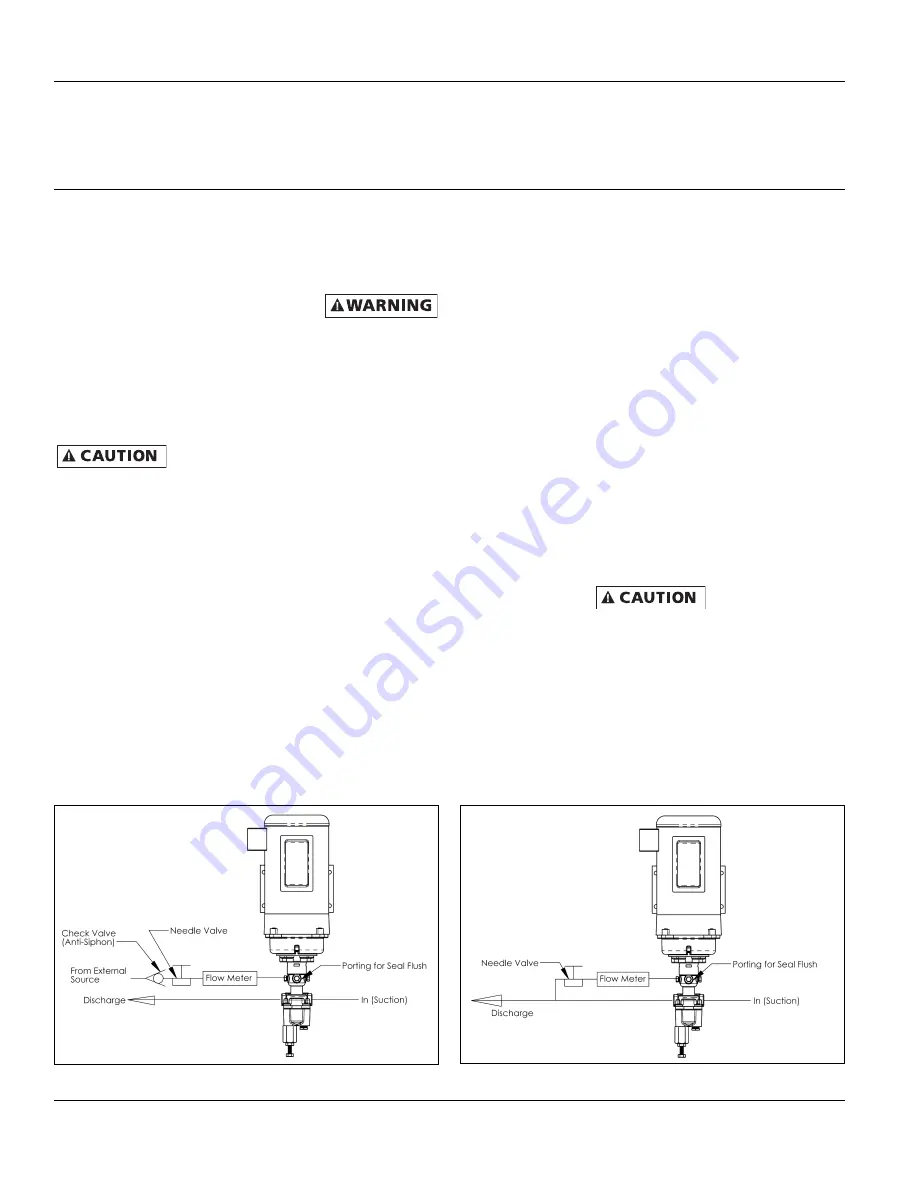

EXTERNAL FLUSH

An external flush system is typically

recommended for applications where

crystallization build-up on the seal is

possible. Some dilution of the working

material must be acceptable to use an

external flush system.

The external flush system (See Figure 5

for typical installation) is commonly

used with liquids where city water can

be used as the neutral flush fluid. City

water is taken from an external source

such as a tap, hose, or special plumbing

fixture and is regulated into the seal

cavity by means of a needle valve and

flowmeter. Use of an anti-siphon check

valve is required.

It is essential that an

anti-siphon check

valve be installed between the pump and

the city water supply to prevent any back

flow from possibly contaminating the city

water supply. Failure to do so could result in

contamination of the water supply with con-

sequential damages. Manufacturer assumes

no responsibility for failure of user in not

providing safeguards to city water systems.

Step 1:

Locate appropriate city water

supply and install anti-siphon check

valve.

Step 2:

Use appropriate pipe nipple to

reduce piping to 1/8”.

Step 3:

Install appropriate needle valve

and flowmeter.

Step 4:

Connect piping to one of three

available seal flush ports on pump.

Step 5:

Adjust needle valve to achieve

desired flow to seal cavity (recommend-

ed 1 to 3 GPH).

INTERNAL FLUSH

Similar to above but internal supply

(See Figure 6 for typical installation).

Typically recommended for high viscosity

applications ensuring lubrication to the

mechanical seal.

In an internal flush system, the fluid is

taken from the discharge and regulated

from 1 to 3 GPH (Gallons Per Hour) to

the seal cavity by means of a flowmeter

and needle valve.

Step 1:

Select a T pipe coupling that is

consistent with discharge pipe size and

material. Couple to discharge piping.

Step 2:

From this coupling, attach a

needle valve with appropriate nipple

reducing to 1/8” pipe or tube. Install

appropriate flowmeter.

Step 3:

Connect 1/8” pipe or tube to

one of three available seal cavity

flush ports.

Step 4:

Adjust needle valve to desired

flow into seal cavity (recommended

1 to 3 GPH).

For alternate flush

systems for hazardous

fluid applications, hot liquid transfer, and

those not addressed in this booklet, consult

a qualified fluid handling specialist for

assistance in specifying and installing flush

systems according to local, state and federal

environmental laws.

SHURflo Commercial-Duty Filter and Rendering Oil

Rotary Close-Coupled External Gear Pumps

8

Models NG7V, NG11V, NG7V-PH and NG11V-PH

SHURflo Operating Instructions, Performance,

Specifications and Parts Manual

Form L-4092 (3/10)

Figure 6 - Internal Flush

Figure 5 - External Flush