27

Startup and Operation

4

Startup and Operation

Precautions

Important

Shively Labs will not accept responsibility for antenna failure due to

operation without proper purging or positive pressure of dry air or dry

nitrogen.

Pressurization

After the antenna is installed and all lines are connected, it is necessary to

check the system for leaks, purge with dry gas (cylinder dry nitrogen or air

from a compressor-dehydrator) to remove all moisture, and leave the system

pressurized with dry gas to avoid future infiltration of moisture. These steps

must be taken before RF power is applied to the system.

CAUTION

When pressurizing the system, never use a "garage" air compressor, as

it will not clean the air and will blow both moisture and contaminants

such as oil and graphite into the coaxial system.

Test for leaks

a. Connect a source of dry gas (cylinder nitrogen or air from a compressor-

dehydrator) to the system as shown in

Figure 14

on page 28.

CAUTION

Be sure to use a good quality pressure gauge which will read accurately

in the 5 - 20 psig (35 - 135 kPa) range; don't depend on the cylinder

gauge, which will not be accurate at a low pressure.

b. Pressurize the system to seven (7) psig, then close the shutoff valve. Give

the system one half hour to stabilize, then record the pressure and the

temperature.

c. Wait twenty-four hours, then read the pressure and the temperature again

and use the pressure correction formula at left to obtain a corrected pressure

for comparison.

d. If the system loses pressure at an unacceptably high rate, re-pressurize it,

leaving the gas supply on. A rule of thumb is that the final pressure should

not be less than half the initial pressure after twenty-four hours.

e. Find the leak(s), using a leak detector or soap bubbles. (The most common

cause of leakage is an O-ring pinched in a flange.)

f. Correct any leaks that are found. Then repeat the leak test until the results

are satisfactory.

Purge the system

All pressurized Shively Labs antennas have a pressure relief valve at the top of

the feedline (center-fed feedlines have a relief valve at each end). This valve is

set to open at about 10 psig. So, to purge the system, it is not necessary to

send a worker to the top of the antenna to open a valve or loosen a flange.

Simply raise the internal pressure enough to open the relief valve. When the

purge is complete, lower the pressure and the valve will close.

When the system is new, and any time that it has been opened, it must be

purged with dry gas before operation to eliminate moisture. The dry gas used

may be dry cylinder nitrogen or air from a compressor-dehydrator.

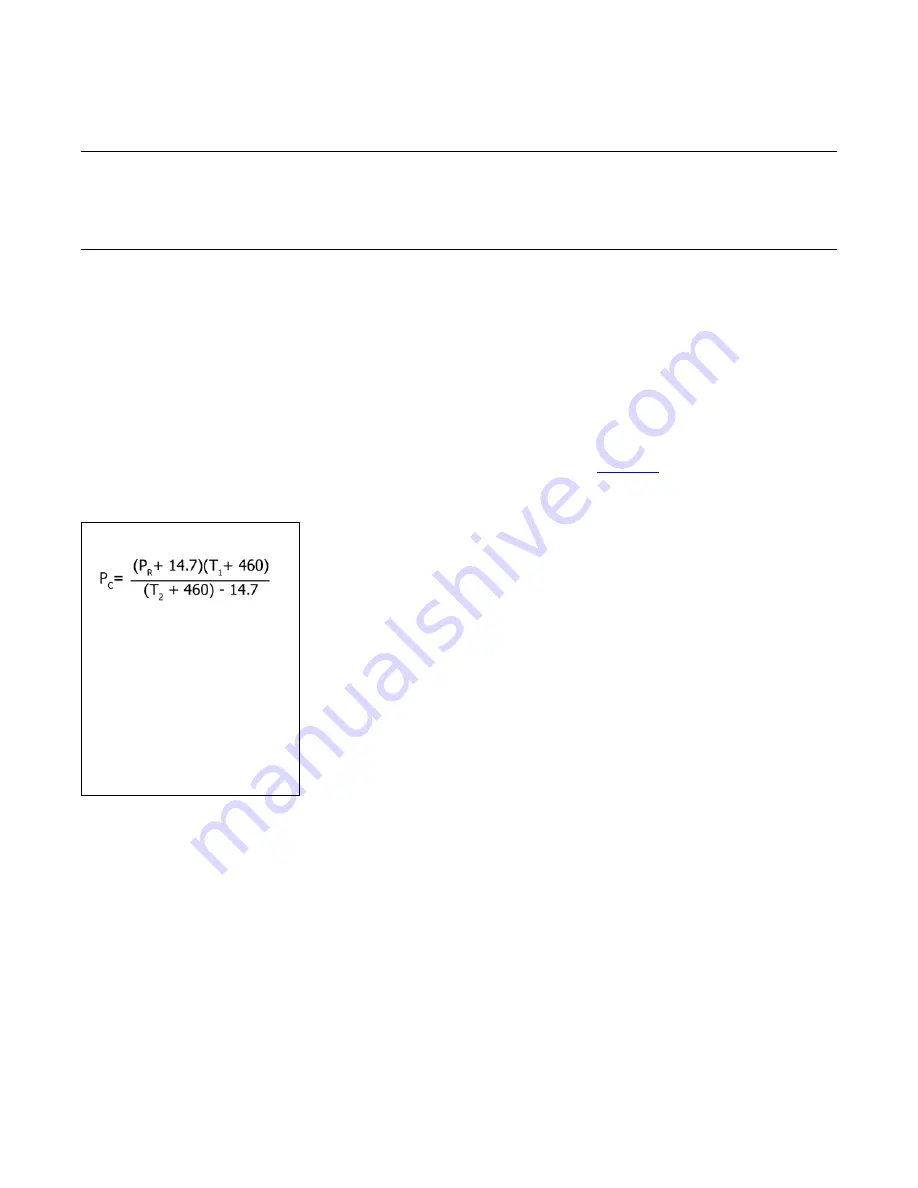

Pressure Correction:

where P

C

= corrected

final pressure, psig

P

R

= final pressure as

read, psig

T

1

= beginning tempera-

ture, degrees F.

T

2

= final temperature,

degrees F.