Connect the inter-panel signal wiring to terminals 1 & 2

on the power supply board, observing polarity.

WARNING. Ensure that cable screen,

armouring or conduit is connected to earth

at both ends of each run. Termination

boards must be connected to cable screens

or earth. Failure to carry out these instructions

WILL result in intermittent faults invalidate the

Declaration Of Conformity.

Two core cable as speci

ed in appendix A, must

be run between all alarm panels, remote transmitters,

plant to alarm interfaces and computer interfaces.

WARNING. A minimum of 20mm clearance

must be maintained between the alarm

system cabling and any other cables

(including the mains supply to the alarms).

Cabling as speci

ed in appendix A must be run

between alarm condition source (plant, manifold etc.)

and the transmitter from which the service is to be

transmitted. (One core per con common for each

service).

Connect alarm condition cabling between

transmitter & plant, terminating at the plant with a

termination board.

WARNING. Where over 5 Gases are

displayed at the Central location (i.e. more

that one panel is present). Connect the

remote 'common', 'mute' & 'test' terminals

on power supply, to similar terminals in the

adjacent alarm(s).

Section 4

TRANSMITTERS

Transmitters introduce signals from plant etc.

onto the multiplexed signal wiring. They also monitor the

wiring between the between the plant contacts and the

transmitter terminals via termination boards mounted in

or near the plant, checking for short or open circuits of

the cable.

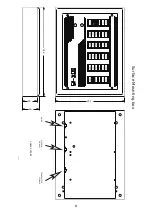

INTERNAL TRANSMITTERS (ITX)

Internal transmitters are available as 1, 2, 3

or 4 service units and are mounted, 1 per 1-5 service

alarm, in the alarm panel enclosure. If a fault is detected

on the contact lines, an alarm condition is transmitted

for the condition relating to the faulty line, and a system

fault visual and audible alarm will appear on this panel.

Each service on the system is allocated a

channel when the system is initially set up, this being

entered on the log sheet. The alarm contacts on the

plant or manifold are connected via the termination

board to a service on the transmitter as follows:-

C

Common

1

First condition

2

Second condition

3

Third condition

4

Pressure fault

and this service is then set to the channel for this service

with the rotary switch. For example, if Oxygen is

allocated channel 1, this plant could be connected to

service A terminals on the transmitter, which would then

be set to channel 1.

Any condition not transmitted from this

transmitter must be terminated with a 56k resistor to set

the condition to normal if the condition is not to be used,

or with a 1k8 resistor if the condition is to be transmitted

from another transmitter. The resistors are used to

prevent a system fault due to short or open circuit. Note

that if a resistor is

tted, the condition must NOT be

connected to the termination board.

Resistor codes:-

1k8 brown grey red silver, gold or red

56k green blue orange silver, gold or red

Important. Ensure that each condition is

only transmitted from one location although

other conditions on the service may be

transmitted from other transmitters.

Any service can be displayed on any alarm panel

by selecting the channel on which the service is

transmitted (by reference to log sheet) using the rotary

switch for the appropriate column on the alarm.

Internal transmitters are powered by the alarm

panel power supply or the reserve battery in the event of

a power failure. Should the power remain o

for long

enough to discharge the battery, all conditions

transmitted from this transmitter will show on other

alarm panels as gas fault conditions (i.e. not system

fault).

REMOTE TRANSMITTERS (RTX).

The Remote transmitter is a self contained unit,

used where indication of the alarm condition is not

required locally, e.g. when a manifold or plant has an

integral plant to alarm interface, and are available as 1,

2, 3 or 4 service units. The services are selected, as in

the alarm panel, with a rotary switch. However, the

remote transmitter has only one switch for up to 4

services. This switch is set to the

rst service required

and the other services will follow in sequence. e.g. if the

switch on a 3 service transmitter is set to channel 2 then

the services transmitted will be channels 2, 3 & 4.

Connection to the plant (or manifold) is identical

to the internal transmitter above.

A 230Vac, 50/60 Hertz supply is required, which

is connected under the mains terminal cover.

The 2 core inter-panel wiring is connected to

signal terminals 1 & 2. The cable screen must be

connected to the ``S'' terminal. Refer to the instruction

sheet supplied with the transmitter.

RTX1 TRANSMITTER

Again, the RTX1 is a self contained transmitter,

used where indication of the alarm condition is not

required locally and is available as a single channel

variation only.

These transmitters are often factory

tted by

Plant or Manifold Controller manufacturers within the

same housing as the contact sources, hence the board

C

1

2

3

4

SERVICE A

C

1

SER

C

C

1

1

2

2

3

3

4

4

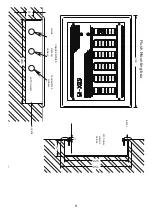

TO ALARM

TO PLANT

CABLING BETWEEN

TRANSMITTER AND

TERMINATION BOARD

TERMINATION BOARD.

TO BE MOUNTED IN

CONTROL PANEL ON

PLANT OR MANIFOLD.

WIRING TO PLANT

ALARM CONTACTS

SDXPIC3

TRANSMITTER

TYPICAL TRANSMITTER

CONNECTIONS SHOWING

ONE UN-USED ALARM

CONDITION LINKED OUT

WITH A RESISTOR

TERMINALS

4