4

23003

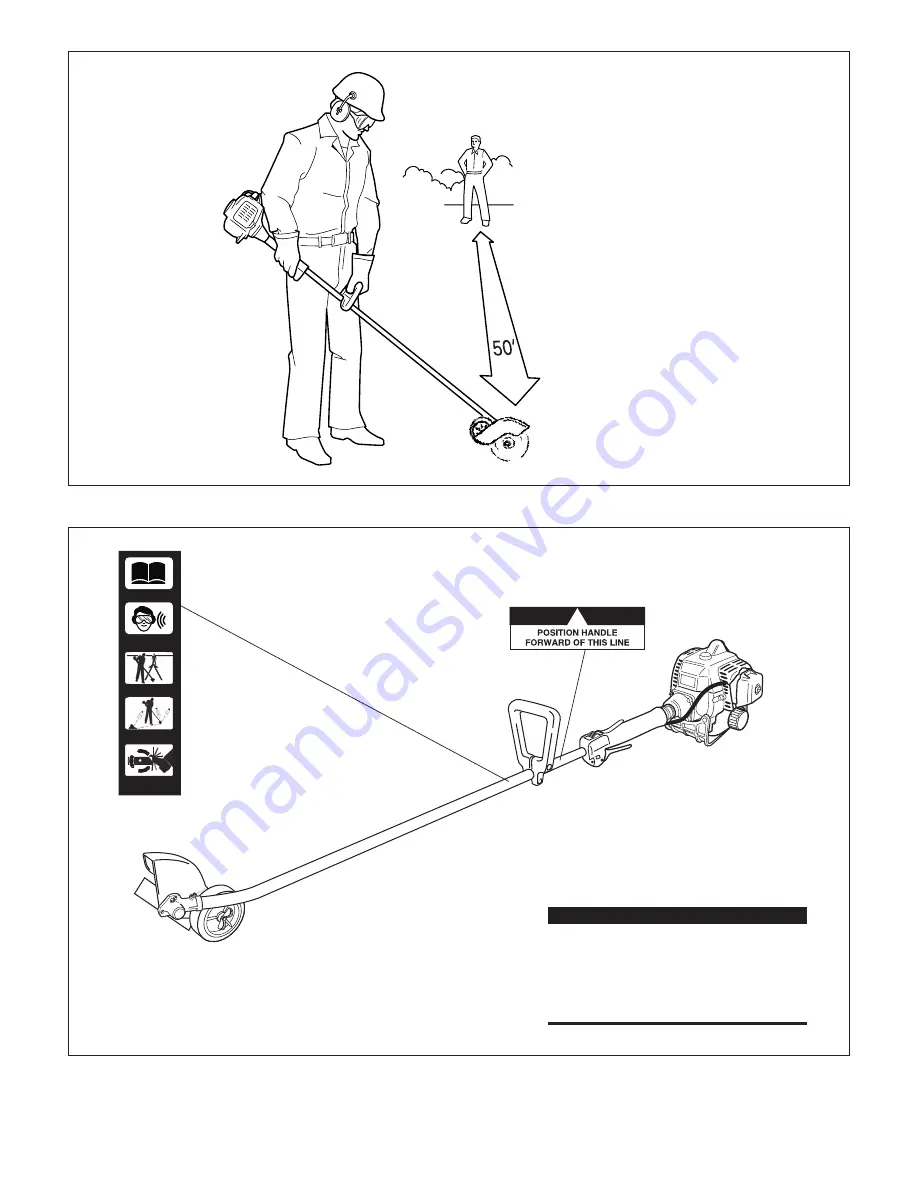

Be Aware of the Working Environment

Avoid long-term operation

in very hot or very cold

weather.

Make sure bystanders or observers

outside the 50-foot “danger zone”

wear eye protection.

Be extremely careful

of slippery terrain,

especially during

rainy weather.

ALWAYS

make sure the

appropriate cutting

attachment shield

is correctly

installed.

If contact is made with

a hard object, stop the

engine and inspect the

cutting attachment for

damage.

Be constantly alert for objects and

debris that could be thrown either

from the rotating cutting attach-

ment or bounced from a hard

surface.

Reduce the risk of

bystanders being struck

by flying debris. Make

sure no one is within 50

feet (15 meters)—that’s

about 16 paces—of an

operating attachment.

Beware of a coasting blade when

edging. A coasting blade can injure

while it continues to spin after the

throttle trigger is released or after the

engine is stopped.

Figure 2

50

FEET

ALWAYS

clear your work area of trash or hidden

debris that could be thrown back at you or toward a

bystander. When operating in rocky terrain or near

electric wires or fences, use extreme caution to avoid

contacting such items with the cutting attachment.

Safety Labels

Figure 3

IMPORTANT!

Safety and Operation Information Labels:

Make sure all information labels are

undamaged and readable. Immediately

replace damaged or missing information

labels. New labels are available from your

local authorized Shindaiwa dealer.

LE230

50 FEET

(15m)

KEEP BYSTANDERS AWAY

AT LEAST 50 FEET (15m)

BEWARE OF THROWN OR

RICHOCHETED OBJECTS

KEEP AWAY FROM

ROTATING BLADE

Shindaiwa

READ THE

OPERATOR’S MANUAL

WEAR HEARING AND

ANSI Z87.1 APPROVED

EYE PROTECTION

P/N 19422-00046

Содержание LE230

Страница 18: ...18 NOTES...

Страница 19: ...19 NOTES...