3-15

Draining and Flushing the Cooling System

NOTE: Drain and flush the radiator and

engine block every 12 months. Refill with a

50/50 mixture of permanent antifreeze and

clear water.

To drain the cooling system:

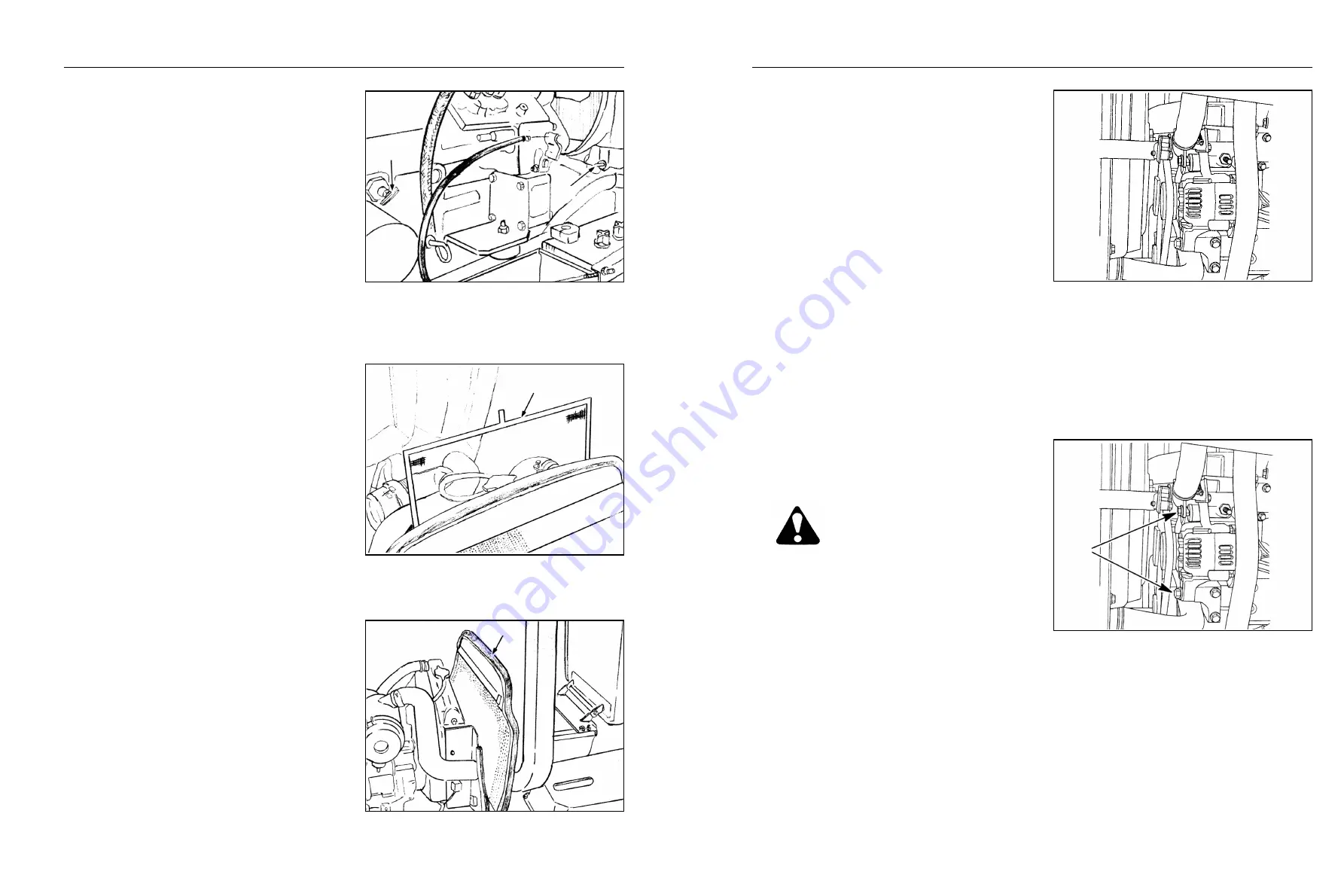

1. Use a suitable receptacle to catch the

used coolant. Remove the radiator cap

and open the radiator drain valve

B

, and

engine block drain valve

A

.

2. After the coolant has drained, place a water

hose in the radiator filler neck and run water

through the system. When water is flowing

from the block drain valve, start the engine.

When the water flowing from the drain valve,

is free of discoloration and sediment, stop the

engine and remove the hose. Allow all water

to drain from the system through the drain

valves.

3. Close the drain valve and slowly refill the

system with a 50/50 solution of permanent

antifreeze and clear water. Fill until the

coolant level is approximately 1.2 cm-2.5

cm (1/2"-1") below the bottom of the filler

neck. Do not fill beyond this level.

4. Clean the radiator cap and cap seal and

install the cap.

5. Fill the coolant recovery reservoir bringing the

fluid level up until it is between the full and

low marks on the reservoir.

6. Pull out the front screen

D

upward and

remove chaff, dust, or other foreign

substances. The foreign substances can be

dropped onto the ground through the rubber

at the lower part.

7. Pull out the radiator screen

C

and clean it.

8. Run the engine until normal operating

temperature is reached, then stop the engine.

Recheck the coolant level when the engine is

cold and add additional coolant as

necessary.

IMPORTANT: Never run the engine when the

cooling system is empty. Do not add cold water

or cold antifreeze solution if the engine is hot.

3-14

LUBRICATION AND MAINTENANCE

Fan Belt

NOTE: Check the condition of the fan belt

after every 50 hours of operation. Check fan

belt tension after every 200 hours of

operation.

A belt-driven fan located at the front of the engine

draws air through the fins of the radiator to lower

the temperature of the radiator coolant.

When 9-11 kg (20-25 lbs.) of thumb pressure is

applied midway between the belt pulleys, a

correctly tightened belt will deflect 10 mm-15 mm

(7/16"-9/16").

If the fan belt is slipping, fan efficiency is lowered,

resulting in the engine running too hot. If the belt

is too tight, the life of the alternator bearing will be

shortened. If the fan belt shows signs of cracking

or fraying, install a new one.

To adjust fan belt tension:

1. Loosen the alternator mounting bolts

A

.

WARNING: NEVER ATTEMPT TO

LOOSEN OR TIGHTEN MOUNTING

BOLTS WITH THE ENGINE RUNNING.

2. Pry the alternator away from the engine and

tighten the mounting bolts.

3. Recheck belt deflection.

FAN BEST

A

ALTERNATOR BELT TENSION ADJUSTMENT

1. Alternator Mounting Bolts

LUBRICATION AND MAINTENANCE

A

B

COOLING SYSTEM

1. Engine Block Drain Valve

2. Radiator Drain Valve

C

3. Radiator Screen

D

4. Front Screen