12

824113

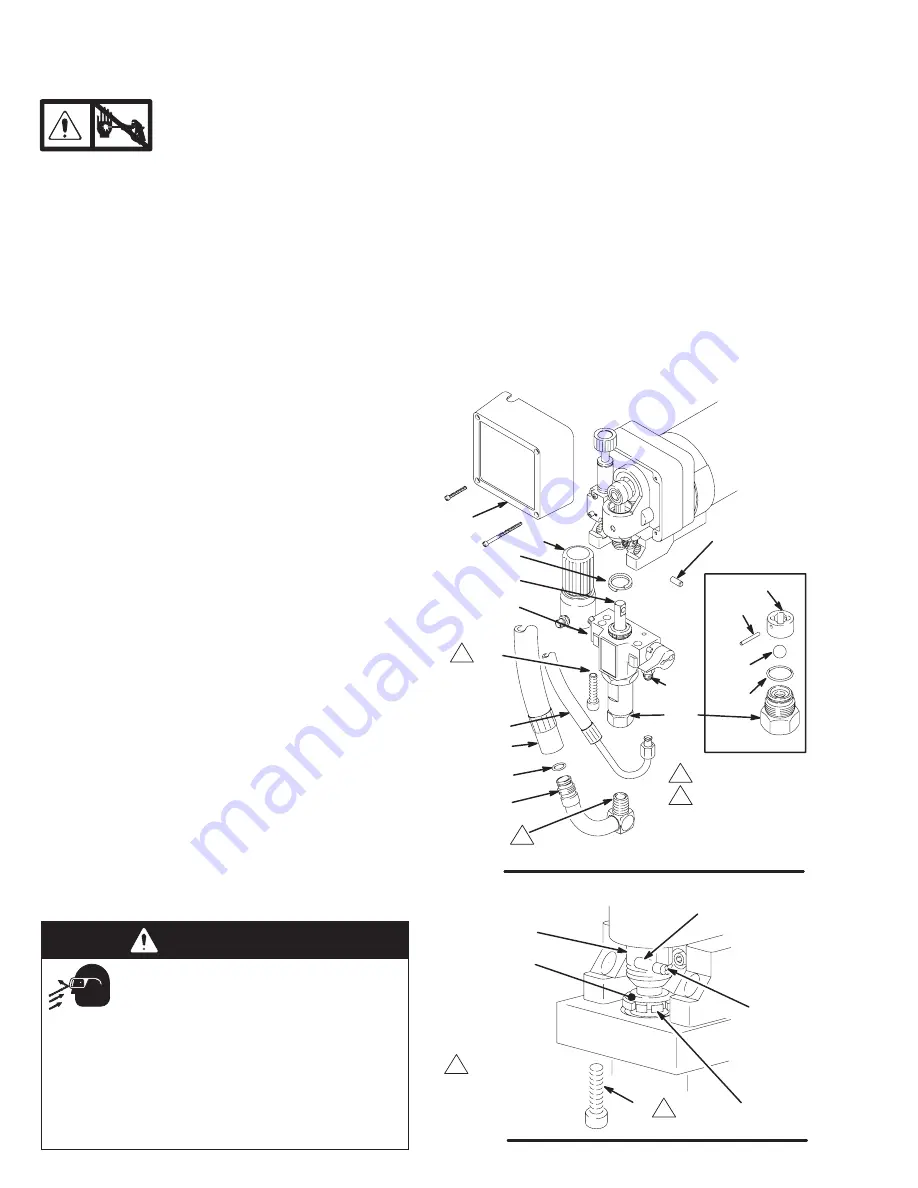

Displacement Pump Repair

Relieve pressure; page 3.

NOTE: Packing Repair Kit 235703 is available. Refer-

ence numbers of parts included in the kit are marked

with an asterisk, i.e., (121*). For the best results, use

all the new parts in the kit, even if the old ones still look

good.

NOTE: To minimize down time, and for the best sprayer

performance, check the motor brushes (see page 10)

and clean the transducer (see page 17) whenever you

repack the pump. Replace these parts as needed.

Removing the pump

(See Fig. 8.)

1.

Flush the pump, if possible. Relieve pressure. Stop

the pump with the piston rod (107) in its lowest

position, if possible. To lower the piston rod manu-

ally, rotate the motor fan blades.

2.

Remove the filter (85).

3.

Remove suction hose or tube (32).(For suction

hose, refer to page 17.

4.

Use a screwdriver to push the retaining spring (18)

up and push out the pin (17).

5.

Loosen the screws (21). Remove the pump (20).

Repairing the pump

See manual 308190 for pump repair instructions.

Installing the pump

(See Fig. 8 and 9.)

1.

Mount the pump on the drive housing. Tap it into

the alignment pins with a soft hammer. Tighten the

screws (21) to 50 ft-lb (68 N.m).

WARNING

MOVING PARTS HAZARD

Be sure the retaining spring (18) is firmly

in the groove all the way around, to pre-

vent the pin (17) from working loose due

to vibration.

See Fig. 9.

If the pin works loose, it or other parts could break

off due to the force of the pump action. These parts

could be projected into the air and result in serious

injury or property damage, including the pump

connecting rod or drive housing.

2.

Align the hole in the rod (107) with the connecting

rod assembly (15). Use a screwdriver to push the

retaining spring (18) up and push in the pin (17).

Push the retaining spring (18) into place around

the connecting rod.

3.

Replace the o-ring (27) if it is worn or damaged.

Reconnect the suction and drain hoses (32,33).

Install the front cover (13).

4.

Tighten the packing nut (102) just enough to stop

leakage, but no tighter. Fill the packing nut/wet-cup

1/3 full with Graco TSL. Push the plug (123) into

the wet-cup.

02832B

Fig. 8

Torque to

50 ft–lb (68 N.m)

Apply anaerobic

polycrystal pipe

sealant

118

*119

*121

*122

120

17

18

20

33

32

38

21

13

107

36

Model 820169 Shown

27

85

Fig. 9

17

18

123

15

102

Torque to

50 ft–lb (68 N.m)

21