18

6. Turn the drum by hand to make sure that everything is clear.

7. Turn the lathe ON.

8. Advance the tool bit manually until

it just contacts the drum surface

momentarily and makes a scratch

cut.

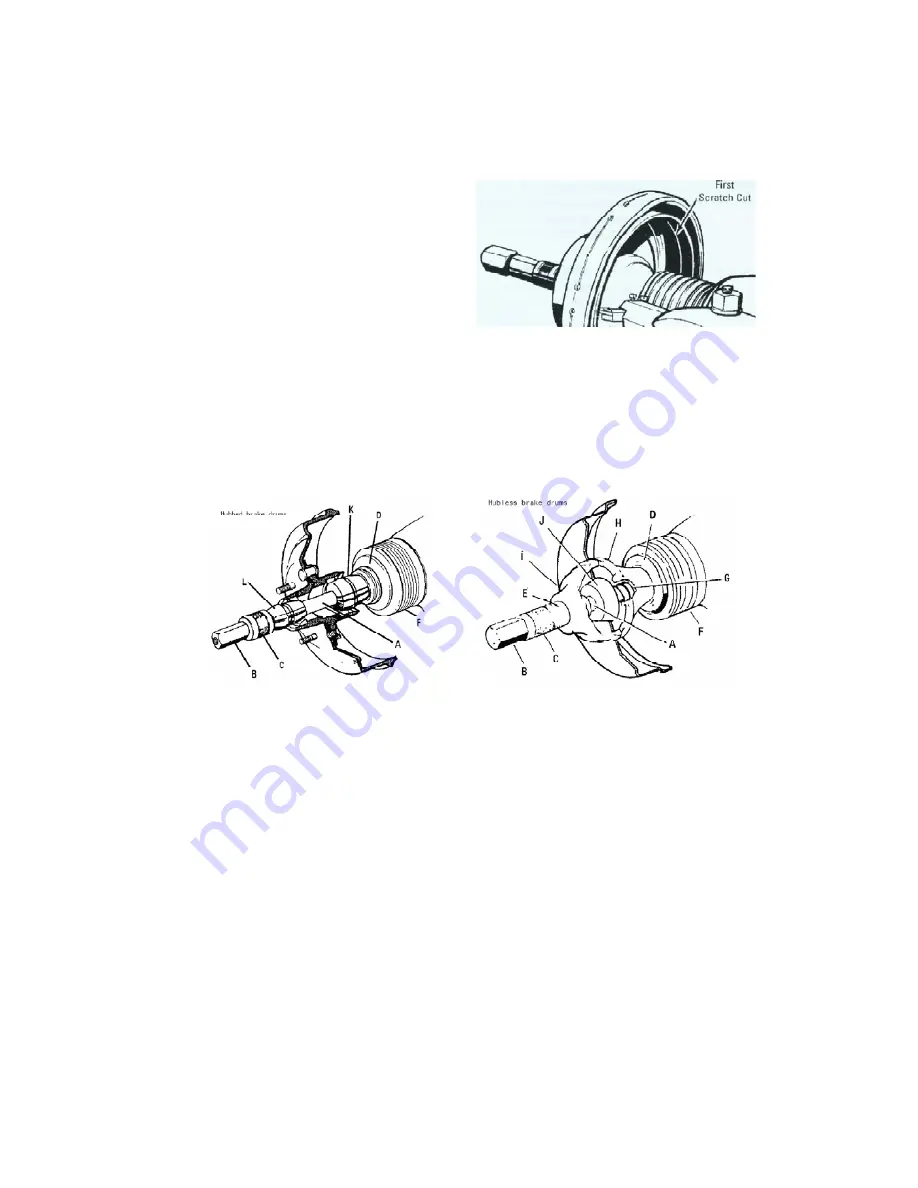

Figure 14 - First scratch cut

9. Back the tool bit off and turn the lathe OFF.

10. Loosen the arbor nut, rotate the drum l/2 turn (180°), and retighten the nut.

11. Turn the lathe ON.

Figure 15-Typical drum mounting configurations

A. 1”Arbor B. Arbor Nut C. Self-Aligning Spacer D

.

Lathe Spindle Nose E. Spacer

F Protective Boot G. Spring H. Inside Floating Adapter I. Outside Floating Adapter

J. Centering Cone K. Large Double Taper Adapter L. Small Double Taper Adapter

Hubbed Brake Drums:Tapered cone adapters fit in the bearing seats, making contact near

the middle of the bearing race whenever possible rather than near an edge. Various

adapters and spacers maybe used to fill out the shaft of the arbor.

Hubless Brake Drums: Slip the hubless adapter onto the arbor followed by Inside Floating

Adapter, a spring, the cone, the drum, and another hubless adapter. Fill out the shaft with

spacers as needed.

Note: The self-aligning spacer should always be used next to the arbor nut when

tightening

.

To avoid over tightening

,

wrench tighten the arbor nut counterclockwise until

the drum and adapters begin to turn on the arbor, then continue to advance the wrench

1

/

16

of a turn

.

Do not over tighten the arbor nut.