9

R-1610

R-1611

R-1612

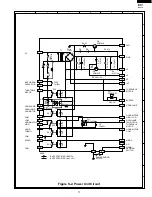

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST

M

KEY UNIT TEST

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. If the display fails to clear when the STOP/CLEAR pad is depressed, first verify the flat ribbon cable

is making good contact, verify that the door sensing switch (stop switch) operates properly; that is the

contacts are closed when the door is closed and open when the door is open. If the door sensing

switch (stop switch) is good, disconnect the flat ribbon cable that connects the key unit to the control

unit and make sure the door sensing switch is closed (either close the door or short the door sensing

switch connecter). Use the Key unit matrix indicated on the control panel schematic and place a

jumper wire between the pins that correspond to the STOP/CLEAR pad making momentary contact.

If the control unit responds by clearing with a beep the key unit is faulty and must be replaced. If the

control unit does not respond, it is faulty and must be replaced. If a specific pad does not respond,

the above method may be used (after clearing the control unit) to determine if the control unit or key

pad is at fault.

5. Reconnect all leads removed

from components during testing.

6. Re-install the outer case

(cabinet).

7. Reconnect the power supply cord

after the outer case is installed.

8. Run the oven and check all

functions.

Q

AH SENSOR TEST

Checking the initial sensor cooking condition

WARNING : The oven should be fully assembled before following procedure.

(1) The oven should be plugged in at least two minutes before sensor cooking.

(2) Room temperature should not exceed 95˚F (35˚C).

(3) The unit should not be installed in any area where heat and steam are generated. The unit should

not be installed, for example, next to a conventional surface unit. Refer to the “INSTALLATION

INSTRUCTIONS” of the operation manual.

(4) Exhaust vents are provided on the back of the unit for proper cooling and air flow in the cavity. To

permit adequate ventilation, be sure to install so as not to block these vents. There should be some

space for air circulation.

(5) Be sure the exterior of the cooking container and the interior of the oven are dry. Wipe off any moisture

with a dry cloth or paper towel.

(6) The Sensor works with food at normal storage temperature. For example, chicken pieces would be

at refrigerator temperature and canned soup at room temperature.

(7) Avoid using aerosol sprays or cleaning solvents near the oven while using Sensor settings. The

sensor will detect the vapour given of by the spray and turn off before food is properly cooked.

(8) If the sensor has not detected the vapour of the food, ERROR will appear and the oven will shut off.

Water load cooking test

WARNING : The oven should be fully assembled before following procedure.

Make sure the oven has been plugged in at least two minutes before checking sensor cook operation.

The cabinet should be installed and screws tightened.

(1) Fill approximately 200 milliliters (7.2 oz) of tap water in a 1000 milliliter measuring cup.

(2) Place the container on the center of tray in the oven cavity.

(3) Close the door.

(4) Touch Sensor reheat pad once and touch the Start pad, Now, the oven is in the sensor cooking

condition and “SENSOR REHEAT” and "COOK" will appear in the display.

(5) The oven will operate for the first 16 seconds, without generating microwave energy.

G 8

5

0

4

9

3

8

2

7

1

6

G 7

Compu

Defrost

Night

Light

Stop

Clear

Memory

Cook

One Dish

Dinners

Lunch on

the Run

Work

Light

Power

Level

Minute

Plus

Popcorn

Fan

Hi / Lo

Turntable

On / Off

Frozen

snacks

Frozen

entrees

Beverage

center

Auto

Fan

Ground

meat

Rice

Fish/

seafood

Fresh

vegetables

Sensor

reheat

Frozen

vegetables

Baked

potatoes

Poultry

Custom

Help

Breakfast

Bar

Super

Defrost

G 6

G 5

G 4

G 3

G 2

G 1

G14

G13

G12

G11

G10

G 9

Kitchen

Timer

Clock

START

Touch On