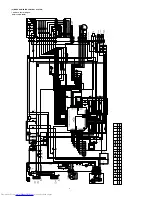

[2] MICRO-COMPUTER CONTROL SYSTEM

1. Electronic Control Diagram

Indoor unit (AH-MP20)

6

MODE

13K

R37

L2

NC

NC

56

L 1

9.1K

R45

1/2W

10K

D14

25V

47

∝

C29

+

NF1

6.8K

6.8K

R41

100

L1

SSR1

C31

1W

275V

0.033

∝

Q8

Q7

Q6

Q5

JP21

3

1

3

1

NR1

CN9

THERMOSTAT

INTERNAL

CN8

CN7

CN6

CN5

CN3

CN2

CN1

1

23

1

CLUSTER

R35 3.3K

R40

R39 10K

CLEANING SWITCH 1

SWITCH 2

CLEANING

3

1

D8

D9

3

2

1

2

3

3

2

2

0.01

∝

C22

16V

2

0.01

∝

C10

16V

22K

R6 20K

Q2

1

R5

22K

R4

R27

2

1/2W

9

470

R30

SSR2

3

12V

5V

10

9

25V C24

SW101

2

11

2

8

IC4

10K

R29

R28

1.8K

BZ1

RY1

SSR1

1/2W

470

IC5

8

9

Q1

16V 220

∝

10K(F)

+

D6

25V

0.1

∝

1

2

4

5

3

MOTOR

LOUVER

3

2

1

5

4

1

2

3

HOLE

IC

FAN

MOTOR

2

3

JP3

JP2

JP1

NC

MB89537A

1

IC6

3

10K

13K

13K

25V

0.1

∝

1

∝

50V

IC1

(PATTERN SIDE)

400V

0.01

∝

16V

JP5

JP4

1K

0.01

∝

OSC1

FR

ON

T

P21 P22 P23 P24 P25 P26 P27

X1 X0

MOD1 MOD0

RST

32 31 30 29 28 27 26 25 24 23 22 21 20

Vcc

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

P45

P46

P47

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

AVR

P60

P61

P62

P63

P64

P31 P32 P33 P34 P35

P36 P37 P40 P41 P42 P43 P44

52 53 54 55 56 57 58 59 60 61 62 63 64

P30

NC

P00

P01

P02

P03

P04

P05

P06

P07

P10

P11

P12

P13

P14

P15

P16

P17

P20

49

50

51

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

AVcc

AVss

Vss

50V

1000p

+

680

10K

10K

10

∝

16V

16V

10

∝

10k

(F)

10K

(F)

4

3

2

1

TH2

PIPE TEMP

15k

!

(25

ы

C).

TH1

PIPE TEMP

10k

!

(25

ы

C).

FAN

MOTOR

2

∝

1

3

5

2.7K(F)

D7

+

35V 1000

∝

50V 0.1

∝

7812

IC2

+

25V 47

∝

7805

0.1

∝

IC3

25V

10V 100

∝

+

C7

D1?4

GND

22.6K(F)

3.3K

4

5

IC8

1

2

3

8

7

6

0.1

∝

25V

16V

0.01

∝

TR1

C1

C2

C3

C4

C5

C6

C8

C9

C11

C13

C14

C15

C17

C18

C19

C20

C21

C23

C25

R7

R8

R9

R10

R13

R14

R15

R16

R18

R19

R20

R21

R22

R23

R24

R25

R26

R32

R34

10K

16V

16V

16V

0.01

∝

0.01

∝

0.01

∝

6.8K

R12

47K

R11

10MHz

JP10

JP11

JP12

JP13

JP18

10K

10K

0.01

∝

16V

0.01

∝

16V

R17 3.3K

13K

C27

C12

SW1 : AUX.(TEST RUN)

C16

25V

0.1

∝

1

R31

R33

+

+

C26

3

2

1

1

BCN1

2

3

4

5

6

7

8

R37

6

7

1

3

5

1K(F)

1

0.1

∝

D12

3

R108

10

32

(TIMER)

LED102

LED101

(OPERATION)

1

1

2

BL

GR

LED107 (CLUSTER)

1

3

42

5

6

9

R107

(FAN L)

(FAN M)

(FAN H)

(FAN AUTO)

LED106

LED105

LED104

LED103

3K

2.7K

R102

R101

1/2W

1/2W

C102

C101

0.1

∝

25V

33

∝

10V

+

IC101

BCN101

R103

R104

R105

R106

620

620

1

2

3

1

8

7

6

5

4

3

2

620

620

1/2W

1/2W

56

CN10

CN103

BCN102

CN102

CN101

275V

275V

0.1

∝

0.1

∝

275V

C28

8

6

SSR2

2W

2W

R1

R2

NC

NC

NC

NC

JP9

JP8

JP7

JP19

DEIC E 1

DEIC E 2

DRY FAN

PIPE 1

PIPE 2

NONE

NONE

NONE

NONE

JP7

JP8

JP9

JP10

JP11

JP12

JP13

TEST

NONE

JP6

NONE

15K

15K

15K

JP18

JP19

LOUV

OUT FAN

CLUS TER

ER

R19

R21

R23

FAN2

FAN1 HEAT

COOL

MODE

R38

R38

ON

PWR

LESS

WIRE

AT

SWE-

KEEP

HOT

DEF.

SYMBOL

I

JP2

JP3

JP4

JP5

JP1

IN

OUT

RY1

WPE1

T

250V

3A

1

N

BOARD

TERMINAL

1

N

PHASE

SINGLE

SUPPLY

POWER

TERMINAL BOARD

A

BL

BK

BR

UNIT

OUTDOOR

TO

NONE

NONE

NONE

47

CT1

BL

BL

Содержание AH-MP20

Страница 3: ... 2 EXTERNAL DIMENSION 3 1 Indoor unit AH MP20 2 Outdoor unit AU MP20 ...

Страница 4: ...4 Indoor Unit AH MP20 Outdoor Unit AU MP20 3 WIRING DIAGRAM CC097 UNIT TO UNIT CORD ...

Страница 7: ...2 PRINTED WIRING DIAGRAM 1 Indoor AH MP20 7 ...

Страница 12: ...CHAPTER 4 TROUBLESHOOTING 12 ...

Страница 13: ...13 ...

Страница 14: ......

Страница 16: ...1 14 16 2 PERFORMANCE CURVES ...

Страница 21: ...3 The Drain pan and related 1 Remove the screw fixing the Drain pan on both side 2 Turn left the Drain hose 21 ...