AY-X36RU

AE-X36RU

29

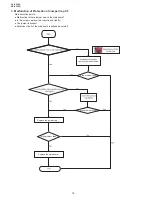

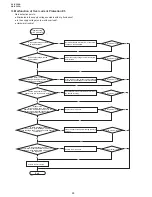

[3] Troubleshooting for Normal Malfunction

1.

Air conditioner can’t be started up

Possible Causes

Discriminating Method (Air conditioner Status)

Troubleshooting

No power supply, or poor con-

nection for power plug

After energization, operation indicator isn’t bright

and the buzzer can’t give out sound.

Confirm whether it’s due to power failure. If yes,

wait for power recovery. If not, check power

supply circuit and make sure the power plug is

connected well.

W r o n g w i r e c o n n e c t i o n

between indoor unit and out-

door unit, or poor connection

for wiring terminals.

Under normal power supply circumstances, opera-

tion indicator isn’t bright after energization.

Check the circuit according to circuit diagram

and connect wires correctly. Make sure all wir-

ing terminals are connected firmly.

Electric leakage for air condi-

tioner.

After energization, room circuit breaker trips off at

once.

Make sure the air conditioner is grounded reliably.

Make sure wires of air conditioner is connected

correctly. Check the wiring inside air conditioner.

Check whether the insulation layer of power cord

is damaged; if yes, place the power cord..

Model selection for air switch

is improper.

After energization, air switch trips off

Select proper air switch.

Malfunction of remote con-

troller.

After energization, operation indicator is bright,

while no display on remote controller or buttons

have no action.

Replace batteries for remote controller.

Repair or replace remote controller.

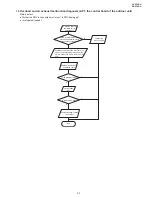

2.

Poor Cooling (Heating) for Air Conditioner

Possible Causes

Discriminating Method (Air conditioner Status)

Troubleshooting

Set temperature is improper. Observe the set temperature on remote controller.

Adjust the set temperature.

Rotation speed of the IDU

fan motor is set too low.

Small wind blow.

Set the fan speed at high or medium.

Filter of indoor unit is blocked.

Check the filter to see it's blocked.

Clean the filter.

Installation position for

indoor unit and outdoor unit

is improper.

Check whether the installation position is proper

according to installation requirement for air condi-

tioner.

Adjust the installation position, and install the

rainproof and sun-proof for outdoor unit.

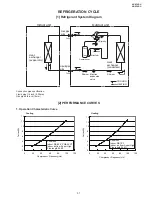

Refrigerant is leaking.

Discharged air temperature during cooling is higher

than normal discharged wind temperature; Dis-

charged air temperature during heating is lower

than normal discharged wind temperature; Unit's

pressure is much lower than regulated range.

Find out the leakage causes and deal with it.

Add refrigerant.

Malfunction of 4-way valve.

Blow cold wind during heating.

Replace the 4-way valve.

Malfunction of capillary.

Discharged air temperature during cooling is higher

than normal discharged wind temperature; Dis-

charged air temperature during heating is lower

than normal discharged wind temperature; Unit’t

pressure is much lower than regulated range. If

refrigerant isn’t leaking, part of capillary is blocked.

Replace the capillary.

Flow volume of valve is

insufficient.

The pressure of valves is much lower than that stat-

ed in the specification.

Open the valve completely.

Malfunction of horizontal lou-

ver.

Horizontal louver can’t swing.

Refer to point 3 of maintenance method for

details.

Malfunction of the IDU fan

motor

The IDU fan motor can’t operate.

Refer to troubleshooting for H6 for maintenance

method in details

Malfunction of the ODU fan

motor

The ODU fan motor can't operate.

Refer to point 4 of maintenance method for

details.

Malfunction of compressor

Compressor can't operate.

Refer to point 5 of maintenance method for

details.

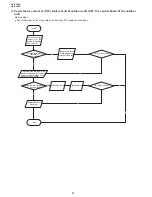

3.

Horizontal Louver Can’t Swing

Possible Causes

Discriminating Method (Air conditioner Status)

Troubleshooting

Wrong wire connection, or

poor connection

Check the wiring status according to circuit dia-

gram.

Connect wires according to wiring diagram to

make sure all wiring terminals are connected

firmly

Stepping motor is damaged Stepping motor can't operate

Repair or replace stepping motor

Main board is damaged

Others are all normal, while horizontal louver can't

operate

Replace the main board with the same model