9

9-1

9-2

14EM4RU

21EM4RU

HORIZONT

AL

AND VERTICAL

DEFLECTION LOOP

ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

V

-SLOPE (I

2

C

BUS CON-

TROL)

V

-SHIFT

-50

(I

2

C BUS

CONTROL)

V

-AMP50 (I

2

C

BUS CON-

TROL)

H-SHIFT (50)

(H-CENTER)

S-CORREC-

TION

(I

2

C BUS

CONTROL)

SUB-SHARP-

NESS

Focus

1.

Receive Monoscope Pattern Signal.

2.

Call the "V

-LIN" mode.

3.

Increase or decrease "V

-LIN" by V

olume key till

the horizontal line in the center of monoscope is

just at the position where the blanking starts.

1.

Call the "V

-CENT" mode.

2. Increase or decrease "V

-CENT" by V

olume key

till the picture is centered.

1.

Call the "V

-AMP" mode.

2.

Increase or decrease "V

-AMP" by V

olume key to

set overscan of 9.5% typical.

Adjustment Spec 9.5% range +1% -0%.

1.

Call the "H-CENT" mode.

2.

Increase or decrease "H-CENT" by V

olume key

to center the picture horizontal.

1. SET

DA

T

A

T

O

(17 for 14") and (20 for 21").

* Check the E-5 CH Monoscope Pattern then re-

adjust V

-Slope, V

-Shift and V

-Amp to makesure

adjustment is in acceptable Ring-Shaped.

1. SET

DA

T

A

T

O

20.

1

2

3

4

5

1.

Receive the "Monoscope Pattern" signal.

2.

Press R/C to set Picture NORMAL condition.

3.

Adjust the focus control to get the best focusing.

1

P

A

L

CHROMA

ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

SUB COLOUR

(I

2

C BUS

CONTROL)

1.

Receive the "P

AL

Colour Bar" signal.

2.

Press R/C to set Picture Normal condition.

3.

Connect the oscilloscope to

Red cathode (D881 Cathode) for 14".

Red cathode (D882 Cathode) for 21".

»

Range

: 20 V/div

. (AC) (Using 10:1 probe)

»

Sweep time

: 10

µ

sec/div

.

4

.

Using the R/C call "SUB COL" in SER

VICE mode.

Adjust SUB COLOUR bus data, so that the 75%

White & Red portions of P

A

L

Color Bar be at the

same level shown as

Fig. 1-1

.

5.

Add another 6 step up into the value of SUB-COL

obtained in (4)

6. Clear the SER

VICE mode.

1

Cy

G

B

W

Y

100%W

75%

Mg

R

Fig. 1-1

CRT CUT

-OFF

, BACKGROUND

AND SUB-CONTRAST

ADJUSTMENT

(Continued)

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

Max

beam check

1.

Receive the "Monoscope Pattern" signal.

2.

Press R/C to set Picture NORMAL condition.

3

.

Connect the DC miliammeter between

TP603 (+)

&

TP602 (–). (Full Scale: 3 mA

Range)

4

.

Beam current must be within 800

±

100

µ

A (14")/

1,100

±

100

µ

A (21").

4

6

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

SUB-TINT (I

2

C

BUS CON-

TROL)

1.

Receive the "NTSC 3.58 Colour Bar" signal thru

A

V

in.

2.

Connect the oscilloscope to

TP47B (P882 pin 5)

BLUE-OUT

.

»

Range

:

100mV/div

. (AC)(Use Probe 10:1)

»

Sweep time

: 10

µ

sec/div

.

3.

Call the "SUB-TINT" mode in service mode.

Ad-

just the "SUB-TINT" bus data to obtain the wave-

form shown as Fig. 1-1.

4.

Clear the SER

VICE mode.

1

Fig. 1-1

NTSC CHROMA

ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

BEAM PRO-

TECT

OR

1.

Receive "Monoscope Pattern" signal.

2.

Set CONTRAST MAX.

3.

Set BRIGHT MAX.

4.

During the Collector & Emitter of Q883/5/7 short,

make sure the protector ON and switch to standby

mode.

1

* Select one of Q883/5/7 to do

each short test.

H•V PROTEC-

TO

R

1.

Receive "Monoscope Pattern" signal.

2

.

Connect output of Bias Box to D603 cathode

(R610 side).

3

.

Set voltage of Bias Box to 18V and make sure

the protector is not work.

4

.

Set voltage of Bias Box to 27V

, and make sure

the protector is work.

2

Other

protectors

1.

Once finish rectified Electrolytic Capacitor short

testing in +B line, check all possible damaged

components on +B line.

(Use random selected set for inspection)

3

PROTECT

OR OPERA

TION CHECKING

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

VIDEO AND

AUDIO

OUTPUT

CHECK

1.

Receive the "P

AL

Color Bar" signal (100% White

Color Bar

, Sound 400 Hz 100% Mod).

2

.

T

erminate the V

ideo output with a 75 ohm imped-

ance.

Make sure the output is as specified (1.0

Vp-p

±

3 dB).

3

.

T

erminate the

Audio output with a 10k ohm im-

pedance.

Make sure the O/P is as specified

(1.76 Vp-p

±

3 dB).

1

VIDEO AND

AUDIO INPUT

CHECK

1

.

Using the

TV/A

V key on the remote controller

,

make sure that the modes change in order of

TV

,

A

V

&

TV again and the video & audio output are

according to the input terminal for each mode.If

connect input to Front and Rear

A

V

terminal, in-

put terminal of Front

A

V

will be selected.

2

A/V INPUT

AND OUTPUT CHECKING

W

Y

Cy

G

M

g

R

B

SAME LEVEL

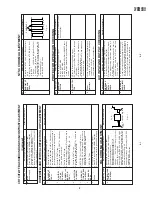

Содержание 14EM4RU

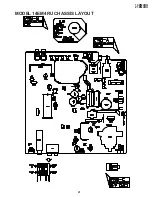

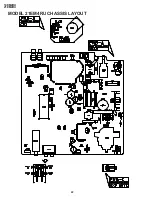

Страница 21: ...21 14EM4RU 21EM4RU MODEL 14EM4RU CHASSIS LAYOUT ...

Страница 22: ...22 14EM4RU 21EM4RU MODEL 21EM4RU CHASSIS LAYOUT ...

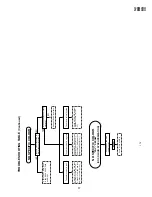

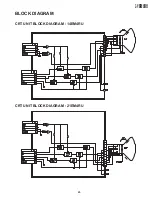

Страница 23: ...23 14EM4RU 21EM4RU BLOCK DIAGRAM CRT UNIT BLOCK DIAGRAM 14EM4RU CRT UNIT BLOCK DIAGRAM 21EM4RU ...

Страница 24: ...24 14EM4RU 21EM4RU BLOCK DIAGRAM MAIN UNIT 14EM4RU ...

Страница 25: ...25 14EM4RU 21EM4RU ...

Страница 26: ...26 14EM4RU 21EM4RU BLOCK DIAGRAM MAIN UNIT 21EM4RU ...

Страница 27: ...27 14EM4RU 21EM4RU ...

Страница 28: ...28 14EM4RU 21EM4RU BLOCK DIAGRAM HEADPHONE UNIT BLOCK DIAGRAM ...

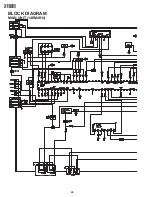

Страница 30: ...30 14EM4RU 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 MAIN UNIT 14EM4RU SCHEMATIC DIAGRAM ...

Страница 31: ...31 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Страница 32: ...32 14EM4RU 21EM4RU MAIN UNIT 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 ...

Страница 33: ...33 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Страница 34: ...34 14EM4RU 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 CRT UNIT 14EM4RU CRT UNIT 21EM4RU ...

Страница 35: ...35 14EM4RU 21EM4RU A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 HEADPHONE UNIT ...

Страница 37: ...37 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Страница 38: ...38 14EM4RU 21EM4RU PWB A MAIN UNIT Chip Parts Side A B C D E F G H I J 1 2 3 4 5 6 7 8 9 10 ...

Страница 39: ...39 14EM4RU 21EM4RU 10 11 12 13 14 15 16 17 18 19 ...

Страница 49: ...49 14EM4RU 21EM4RU ...