13

12

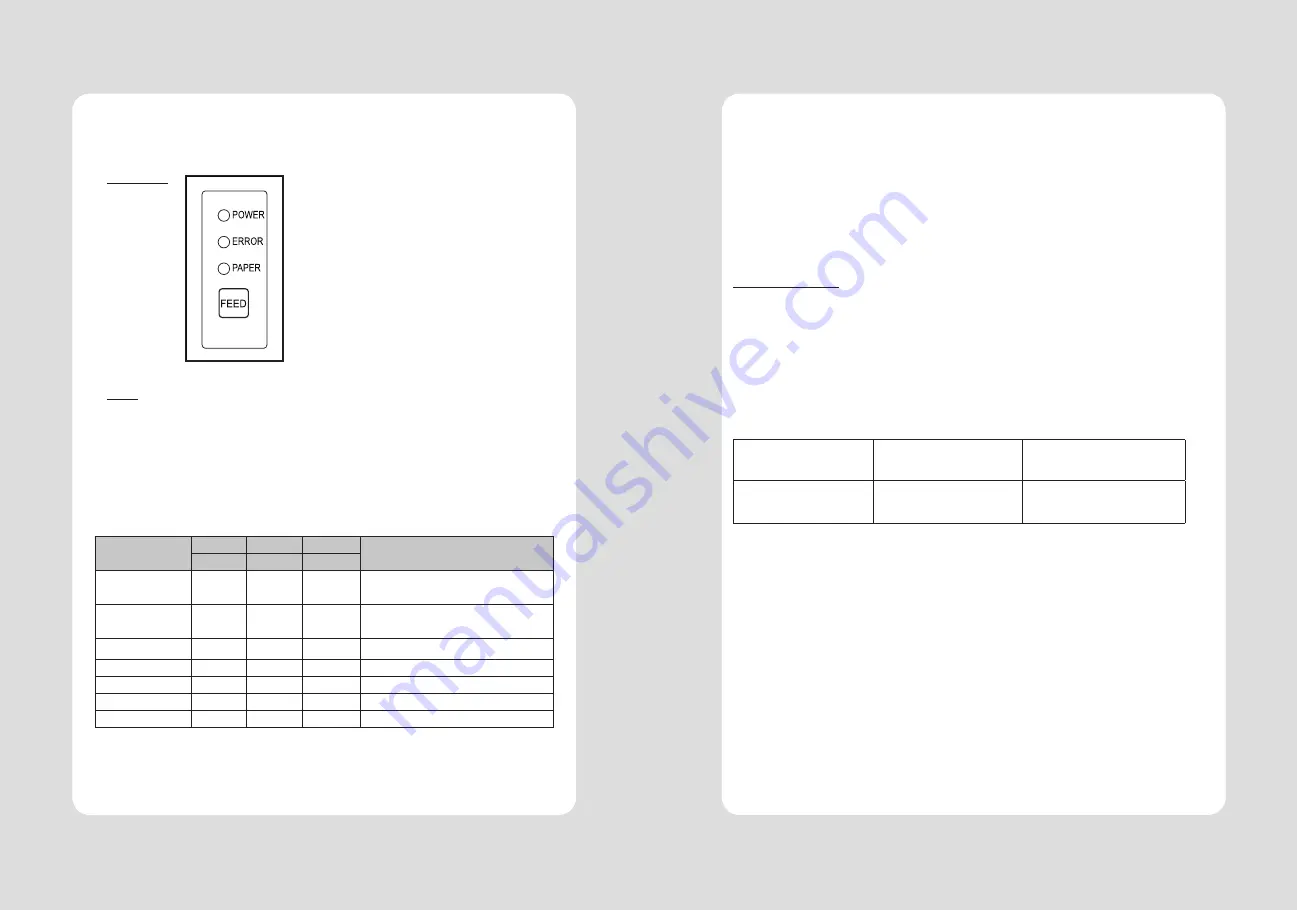

3-1. Control panel

You can control the basic paper feeding operations of the printer with the button on the control panel.

The indicator lights help you to monitor the printer’s status.

Control Panel

Button

The button can be disabled by the ESC c 5 command.

Press the FEED button once to advance paper one line. You can also hold down the FEED button to

feed paper continuously.

3-2. Error indicators

This section explains the different patterns signaled by the three LED indicators located on the top

cover of the printer.

STATUS

PAPER

ERROR

POWER

REMARKS

RED

RED

GREEN

Power off

OFF

OFF

OFF

Normal power is not supplied to

the printer

Power on

OFF

OFF

ON

Normal power is supplied to the

printer

On line

OFF

OFF

ON

Normal error-free mode

Cover open

OFF

ON

ON

Close cover

Paper empty

OFF

ON

ON

Insert new paper roll

Paper near end

ON

OFF

ON

Paper is low

Test mode

OFF

OFF

ON

Ignored error led

3. Control panel and other functions

The self-test result indicated whether the printer is operating properly. Also with this, user can check

following options or status of the printer.

Control circuit

Printer mechanism

Printing quality

ROM version

Interface setting

This test is independent of any other equipment or software.

Running the self test

1. Make sure the printer is turned off and the printer cover is closed properly before performing the self test

2. Turn the printer on holding the FEED button, then the self-test will start. The self-test prints the printer

setting value and then prints the following, and pauses. (Error LED On)

SELECT MODE BY BUTTON

1. ASCII PRINT

2. SELECT BAUDRATE MODE

3. HEXADUMP MODE

3. Press the FEED button consecutively (1~3)

1. ASCII PRINT

(press the FEED button once)

2. SELECT BAUDRATE MODE

(press the FEED button twice)

3. HEXADUMP MODE

(press the FEED button triple time)

Printing test page constructed

with ACII code.

Set the speed of Serial Interface

(You can set the BAUDRATE in

this mode)

Printing the HEX value received

from the interface

♣

Wait for 5~6 seconds if you want to exit. Printer performs a cutting when exiting this mode

4. The printer is ready to receive data after finishing setting.

4. Self Test

Содержание SLK-T21EB Series

Страница 2: ......