Section 3

Operation

Part Number 020003997

4/12

3-5

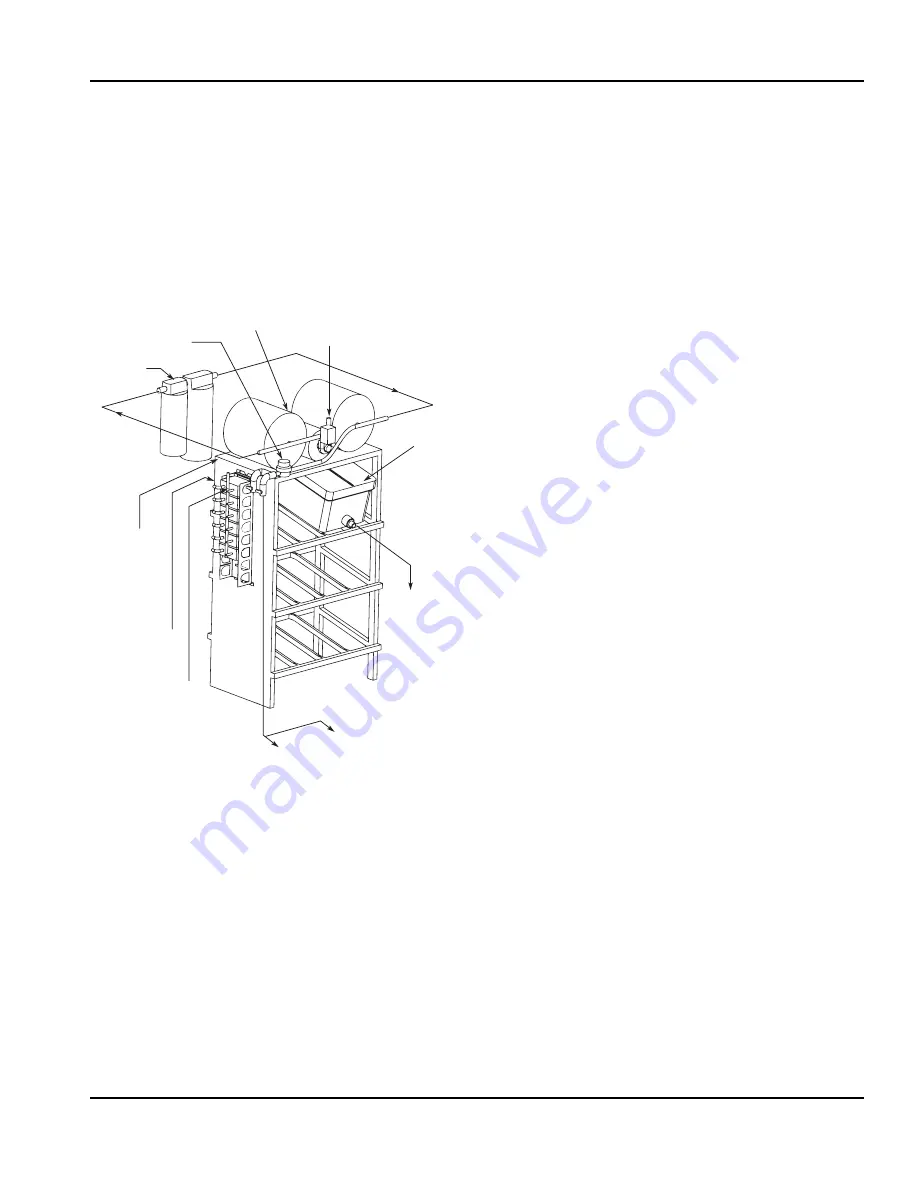

SYRUP DELIVERY SYSTEM

Your syrup location can vary depending on the volume of

beverages served and ease of accessibility. Your beverage

system may set in a back storage room or under the counter of

the dispenser. Configurations are almost limitless. Check the

temperatures expected for the storage location. Adverse

temperatures can affect the storage and quality of beverage

products. It is recommended the temperature of storage location

must not fall below 40°F (4°C) or rise above 90°F (32°C).

BACK ROOM PACKAGE

1.

Incoming tap water –

must be at a minimum dynamic

pressure of 40 psi and maximum static pressure of 55 psi.

2.

Carbonator Water pump motor –

Powers the water

pump. The water pump motor is part of the carbonator

pump deck.

3.

Carbonator Water pump –

Pumps tap water into the

carbonator tank. The water pump is part of the

carbonator. The incoming water for the carbonator must

be first run through the pump before connecting to the

proper cold plate inlet.

4.

Internal/External Carbonator tank –

Combines CO

2

gas and tap water to form carbonated water. The

“carbonator” is the carbonator tank, water pump and

water pump motor.

5.

CO

2

cylinder –

Holds highly pressurized carbon dioxide

(CO

2

). The CO

2

cylinder is a steel or aluminum cylinder

tank. CO

2

gas flows through the primary pressure

regulator.

6.

BIB pressure gauge –

Set for a minimum of 60 psi.

Indicates CO

2

pressure going to B-I-B pumps.

7.

Primary pressure regulator –

Lowers the CO

2

gas

pressure, to 100 psi, so the CO

2

gas will be at the

proper pressure to enter the carbonator regulator.

8.

Lowered outgoing pressure –

Set for 75 psi. Gauge

indicates lowered outgoing pressure from the CO

2

cylinder after being routed through the primary pressure

regulator at 100 psi.

9.

Secondary pressure regulator –

Lowers the CO

2

gas

pressure before the CO

2

gas flows to the syrup pump.

CO

2

pressure activates the syrup pump.

10.

Syrup pump –

Draws syrup out of the bag-in-box syrup

package. Syrup flows through the syrup lines to the

dispenser for chilling, then dispensing. There is a syrup

pump for each bag-in-box syrup system.

11.

Bag-In-Box syrup cartons –

Box which contains a

plastic bag, filled with syrup.

RACKING

Regardless if you are working on a B-I-B or Figal system, a

place will be designated for placement of the product. A rack

(or shelf) system affords systematic placement and

complete usage of the beverage paid for. The B-I-B rack

allows the boxes to lay properly for syrup dispersal. Please

check with your B-I-B syrup supplier. Some boxes must be

slightly tilted down, while others may be in virtually any

position. The Figal tank rack keeps the newer and full tanks

organized at one end of the beverage line with the partial

tanks at the other.

B-I-B

The Bag-In-Box system refers to a plastic disposable bag.

The B-I-B normally contains 5 gallons of syrup, however

some locations offer 2-1/2 gallon B-I-B units. This plastic bag

is then held inside a cardboard or other container. B-I-B

systems are for post-mix applications only.

PUMPS

The syrup in a B-I-B system is delivered to the beverage

system through gas operated pumps. These pumps extract

the syrup out of the bags, forcing the syrup throughout the

system.

AUTO BAG SELECTORS

These are used on higher volume B-I-B systems where two

or more bags of the same product are connected to one

pump and one system. An auto bag selector is essentially a

valve that automatically changes from one bag (or series of

bags) to another bag (or series of bags) of syrup as the bags

empty, allowing a constant flow of product.

From Water Supply

To Noncarbonated

Water Inlet Barb

Water to

Carbonator

Pump

Filter

Water Regulator

40–55 PSI

Booster System

(If Required)

To CO

2

Manifold (BIB

Pumps) from

CO

2

Supply

60 PSI

To Syrup Inlet

Barbs on Unit

To BIB Pumps

from BIB

To BIB

Pump

BIB

Содержание SV-200 SCI

Страница 6: ...Table of Contents continued iv Part Number 020003997 4 12 ...

Страница 33: ...Section 3 Operation Part Number 020003997 4 12 3 9 Control Logic Matrix Flavor Magic ...

Страница 34: ...Operation Section 3 3 10 Part Number 020003997 4 12 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 44: ...Maintenance Section 4 4 10 Part Number 020003997 4 12 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 49: ...Section 5 Before Calling for Service Part Number 020003997 4 12 5 5 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 50: ...Before Calling for Service Section 5 5 6 Part Number 020003997 4 12 THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 51: ......