Diaphragm Relief Valve

Operating Instructions

TA 48

Rev.

13 en

05/2016

Subject to technical modifications!

www.sera-web.com

3

1

General

Before commissioning and during operation of the

sera

dia-

phragm relief valve the respective regulations valid at the place

of installation are to be observed.

sera

diaphragm relief valves are delivered ready for assembly.

Carefully read these instructions and especially the safety in-

structions herein contained before installation and initial start-

up of the valves.

The

sera

diaphragm relief valve protects the pump, fittings,

and pipes from unacceptable overpressure.

2

Types

2.1

Type plate

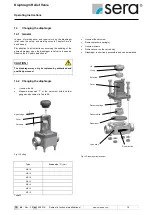

Each

sera

diaphragm relief valve is factory provided with a

type plate. The following information can be found on this type

plate.

1

2

3

4

5

6

Fig. 01 Type plate

Explanation of the indications on the type

plate

1

Pe

Set pressure:

The set pressure corresponds to the

overpressure (at the valve inlet) at

which the valve opens under test condi-

tions (atmospheric pressure at the valve

outlet).

2

Mat.

Materials:

Material specifications for housing / dia-

phragm according to DIN/ISO

3

Type

Diaphragm relief valve type

4

No.

Serial number of the diaphragm relief

valve

5

DN

Nominal width:

The nominal width is a characteristic

parameter which is used for pipes and

parts, e.g. tubes, tube connections, fit-

tings etc. matching each other.

Nominal widths correspond to the pipe

diameter in mm.

6

PN

Nominal pressure:

The nominal pressure is the permissible

operating pressure in bar at 20° C.

Table 01 Explanation of type plate