SECO-LARM Electric Door Strike with Vertical Adjustment

2

SECO-LARM U.S.A., Inc.

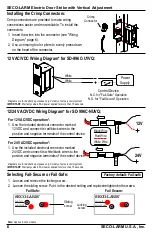

The SECO-LARM SD-996C-U1VQ and SD-996C-NUVQ Adjustable Door Strikes are compatible

with a wide range of lock types including cylindrical, mortise, and mortise exit devices and can be

configured for use in wood, aluminum, or metal doors. Included are various ANSI-sized faceplates

that can be easily installed on the strike to match the door lock type. The strike is easily field-

configurable for fail-safe or fail-secure applications.

Model

SD-996C-U1VQ

SD-996C-NUVQ

Operating voltage

12 VDC/VAC

±

15%

12/24 VDC/VAC

±

15%

Current draw 12VDC

250mA

250mA

24VDC

N/A

150mA

Operating temp.

14°~113° F (-10°~45° C)

Operating humidity

0~95%

Holding force

1,500-lb

Latch throw

1" (25mm) max with

1

/

8

" (3mm) door gap

Dimensions

1

13

/

16

"x1

5

/

8

"x3

5

/

16

" (47x42x84 mm)

Specifications:

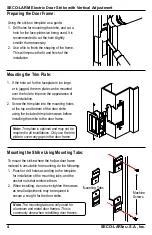

Note: Not all parts will be used in every installation.

1.

Select the type of faceplate that will be used. See “Sample Installations,” on page 5. If the door

is pre-cut for a strike, skip to step 6.

2.

Measure and mark the door latch line and the center line of the door. See “Measuring the

Latch Line & Center Lines,” page 3.

3.

Apply the included stick-on template to the door frame. See “Mounting the Template,” page 3.

4.

Prepare the door frame for installation and mount the trim plate if needed. See “Preparing the

Door Frame” and “Mounting the Trim Plate,” page 4.

5.

If the door frame material is unsuitable for mounting the strike directly, use the included

mounting tabs for installation. This is recommended for aluminum door frames. See “Mounting

the Strike Using Mounting Tabs,” page 4.

6.

Program for either fail-safe or fail-secure operation. See “Selecting Fail-Secure or Fail-Safe,”

page 6.

7.

Connect power and complete installation to frame. See “Wiring Diagram,” page 6.

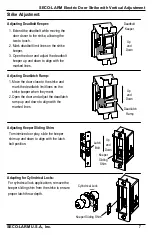

8.

Adjust the keeper if needed to correct for any installation problems, page 7.

Parts List:

Door Strike ................................................. x 1

Faceplates ................................................. x 5

Mounting template ..................................... x 1

Electrical connectors* ................................ x 2

Trim plate ................................................... x 1

Trim plate screws ...................................... x 2

Crimp connectors ...................................... x 2

Mounting tabs ............................................ x 2

Wood screws ............................................. x 2

Machine screws ........................................ x 6

Faceplate screws ...................................... x 2

Self-tapping screws ................................... x 2

Introduction:

Quick Installation:

*Only with SD-996C-NUVQ