Original Language Version

© Jack Sealey Limited

c) Check all tube fittings and electrical connections.

d) Inspect pressure tank inside and out for damage or corrosion.

6.7.

MAINTENANCE SCHEDULE

6.8.

RECOMMENDED OILS

Synthetic oil suitable for temperatures ranging from -5°C to 45°C: Viscosity 5W50. We

DO NOT

recommend using mineral oil in

these compressors.

Part No. Qty. Description

FSO1 1ltr x 12 Compressor oil fully synthetic

FSO1S 1ltr x 1 Compressor oil fully synthetic

FSO5 5ltr x 1 Compressor oil fully synthetic

IMPORTANT WARNING

- Air contaminants taken into the compressor will affect optimum performance. Example: Body filler

dust or paint overspray will clog the pump intake filter and may cause internal damage to pump/motor components. Please note

that any parts damaged by any type of contamination will not be covered by warranty.

7. TROUBLE SHOOTING

Fault

Cause

Remedy

Pressure drop in the

tank.

Air leaks at

connections.

Run compressor to max.

pressure, switch off.

Brush soap solution over

connections and look for

bubbles. Tighten connections

showing leaks. If problem

persists contact Authorised

Service Agent.

Pressure switch

valve leaks when

compressor is idle.

Non-return valve seal

defective.

Discharge all tank pressure.

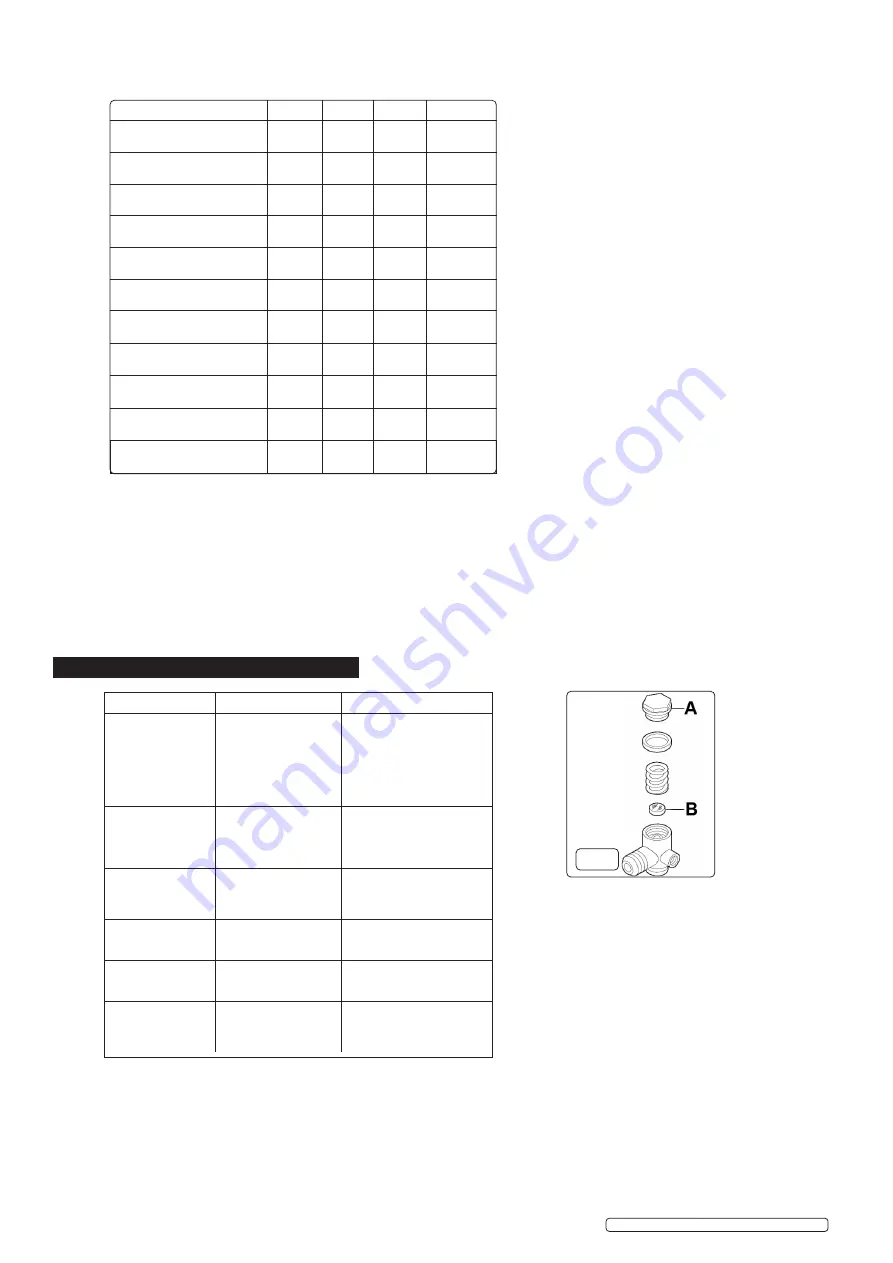

Referring to fig.4, and fig.9,

unscrew valve cap 'A'. Clean

rubber disc 'B' and its seat.

Refit all parts accurately.

Compressor stops

and does not restart.

Power failure.

Motor failure.

Check electricity supply and

fuse.

Contact Authorised Service

Agent.

Compressor does

not stop at max

pressure.

Pressure switch fault.

Contact Authorised Service

Agent.

Compressor does

not reach max

pressure.

Filter clogged.

Head gasket or valve

fault.

Replace filter element.

Contact Authorised Service

Agent.

Compressor noisy

with metallic knock.

Low oil level.

Bearing or piston

damage.

Turn off and top up oil

immediately.

Contact Authorised Service

Agent.

SAC20030B, SAC15030B Issue: 1 08/03/21

Maintenance Operations

Weekly 50hrs

100hrs

400 hrs

Drain condensation

•

Check oil level

•

Clean intake filter

•

Check for oil leaks

•

Replace oil

•

Check cut-out

•

General cleaning of

compressor

•

Replace air filter

•

Check tube fittings and

electrical connections

•

Internal & external

inspection of tank

•

Check and adjust belt

tension

•

fig.9