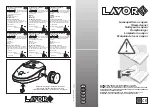

9. blOWinG

WarninG!

Make sure the vacuum is unplugged (fig.6.1).

9.1.1.

Unscrew the hose from the suction port (fig.6.2).

9.1.2.

Insert the hose assembly into the blower socket (on the back of the top cover), rotate it to the right and tighten it (fig.6.3).

9.1.3.

Plug in the machine (fig.6.4).

9.1.4.

Switch on the machine (fig.6.5).

9.1.5.

The unit will now blow through the vacuum hose and can be used to clear obstructions within the hose (fig.6.6)

WarninG!

Before using the blower function, make sure the container is empty

WarninG!

Always wear safety goggles before using the blower. Keep bystanders away from blowing debris and wear a dust mask if

blowing creates dust that might be inhaled.

10. acceSSOrieS

10.1.

P

ower cable winding (fig.7.1).

10.2.

S

torage brush, crevice nozzle, (fig.7.2).

10.3.

S

torage brush, crevice nozzle, floor nozzle, tubes (fig.7.3).

10.4.

A

djust airflow (fig.7.4).

11. maintenance

11.1.

After cleaning the barrel, filters and related accessories, check for leaks. After each use, clean the filter, never use a wet filter.

11.2.

Check the plug for damage, if found to be damaged replace the plug.

11.3.

If suction is reduced check to see if the air intake is blocked, clear any blockages.

11.4.

Carefully empty the machine,

DO nOt

hit the barrel.

11.5.

Keep the machine dry.

11.6.

After prolonged use the filter will be covered with dust, and suction will be reduced. To avoid reducing the suction, clean the filter

regularly. If the filter is covered with dust, wash with water, if necessary, use a mild detergent, refer to section 7.

8

DO nOt

use abrasives to clean.

8

DO nOt

put entire top cover assembly directly into the water.

8

DO nOt

let the machine work for more than 2 hours at a time, doing so will reduce the life of the machine.

11.7.

If any abnormal vibrations, noises or smells occur stop using the machine immediately.

fig.6

fig.7

Original Language Version

© Jack Sealey limited

PC195Sd.V2

Issue 2 (3) 01/11/18