4.2

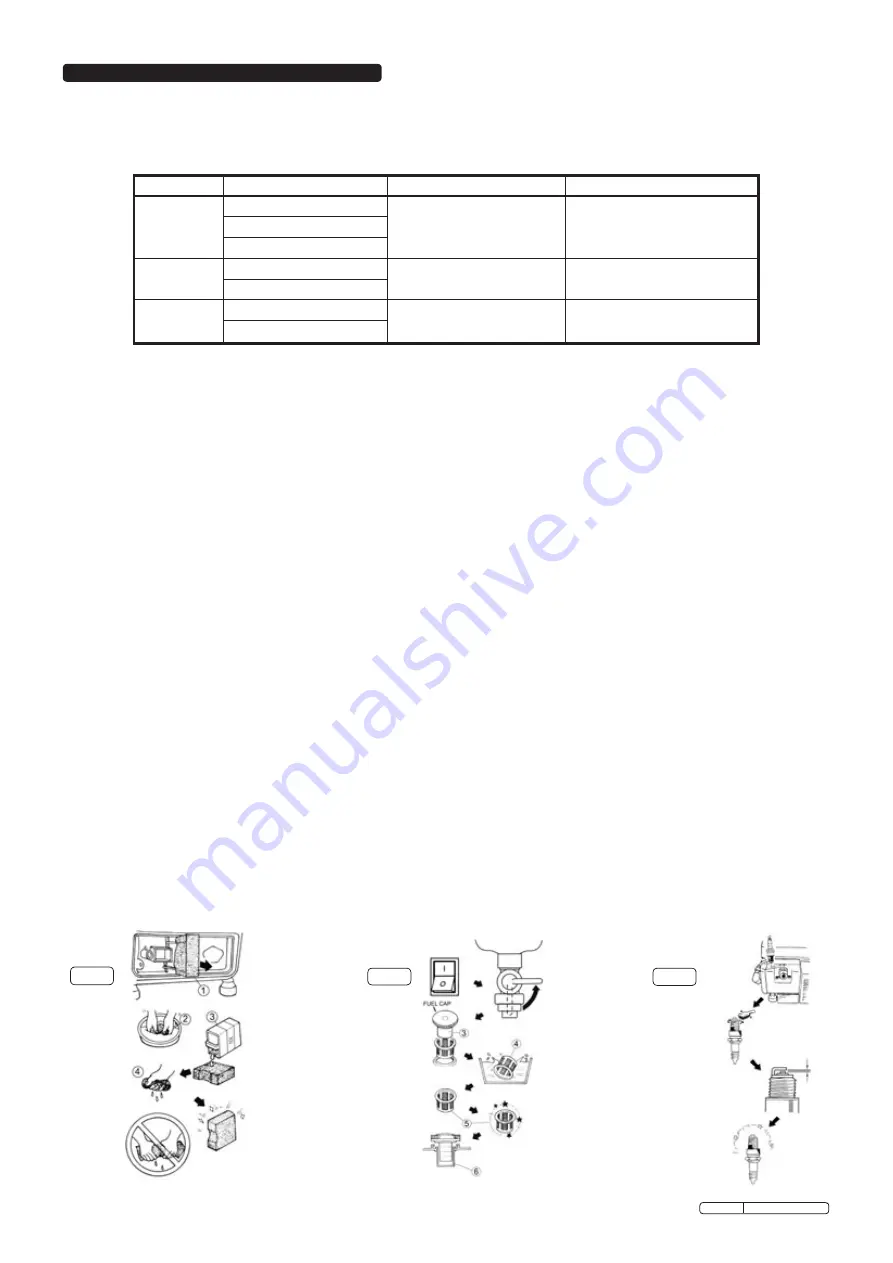

MAINTAINING THE AIR FILTER (fig 4)

Note: If the air filter is dirty, air passing towards the carburettor will be restricted. To avoid the carburettor from malfunctioning,

clean the air filter regularly. Clean more often when the engine is used in extremely dusty places.

WARNING! Never use fuel or solvent to clean the foam element. This can cause a fire or an explosion.

4.2.1

Unscrew the two securing screws and remove the air filter cover.

4.2.2 carefully check the element for tears or holes and replace if damaged.

4.2.3 clean the element using compressed air. Replace the element if it is very dirty.

Note: Never attempt to remove dirt with a brush as brushing could imbed the dirt into the fibres.

4.2.4

Wash the foam element in household detergent diluted in warm water, rinse with plenty of water and dry thoroughly.

4.2.5

Dip the foam element into some clean engine oil and press out to remove any excess oil.

Note: The engine will start smoking during the first start up if too much oil is left on the foam.

4.2.6

The refitting procedure is the reverse of the above.

4.3

CLEANING THE FUEL FILTER (fig 5)

4.3.1 close the fuel valve located on the rear of the generator.

4.3.2

Remove the fuel cap to expose the fuel filter, remove carefully.

4.3.3

Wash the fuel filter with a non flammable high flash point solvent.

4.3.4

Dry thoroughly and refit ensuring the lid is fully tightened.

4.3.5

Open the fuel valve and check for leaks.

4.4

MAINTAINING THE SPARK PLUG (fig 6)

WARNING!

If the engine has just been running, the muffler and the spark plug will be very hot, Allow them to cool.

WARNING!

The spark plug must be correctly tightened. If the plug is not well tightened, it can overheat and damage the engine.

Note: To ensure that the engine performs correctly, the spark plug must not have any deposits on it and its gap must be correct.

4.4.1

Remove the spark plug cap and the spark plug using a spark plug wrench.

4.4.2

Inspect the spark plug and discard it if the electrodes are worn or if the porcelain is cracked or scaled. If the spark plug is to be

re-used, clean with a wire brush.

4.4.3

Measure the electrode gap using a feeler gauge. The gap must be between 0.7mm and 0.8mm. Adjustment of the gap can be

achieved by bending the side electrode.

4.4.4 check the spark plug washer is in good condition and screw the plug in by hand to avoid cross threading.

4.4.5

Once the spark plug is installed, tighten it using a spark plug wrench to compress the washer.

Note: In the case of a new spark plug being fitted, screw it in by hand and tighten it by 1/2 turn with a spark plug wrench to

compress the washer. If the spark plug has already been used, screw it in by hand and only tighten it by 1/8 to 1/4 turn to

compress the washer.

4.5

CLEANING THE GENERATING SET

4.5.1 clean the generating set using a brush and cloth. Remove dust and debris around the exhaust muffler and the cooling fins.

WARNING! DO NOT use a jet wash or get the generating set wet.

4.5.2 clean the engine and alternator air inlets and outlets. Make the most of this cleaning by checking the general condition of the

generating set and change any defective or worn parts.

4. MAINTENANCE

4.1

GENERAL MAINTENANCE SCHEDULE

WARNING!

All maintenance work is carried out when the engine is stopped. If the engine must run, ensure that the working area is

well ventilated. exhaust gases contain carbon monoxide; exposure to this toxic gas can cause loss of consciousness and can be fatal.

WARNING!

If the engine has just been running, the muffler will be very hot, take care not to touch it.

ensure the spark plug HT lead has been disconnected prior to commencing maintenance.

All other maintenance must be carried out by qualified staff, contact your local Sealey service agent.

fig 4

fig 5

fig 6

Item

Remarks

Every 50hrs or Monthly

Every 150hrs or 3 Monthly

Spark Plug

Remove carbon

4

6

Adjust gap

Replace if necessary

Air Filter

clean

6

4

Replace if necessary

Fuel Filter

clean

6

4

Replace if necessary

Original Language Version

GG0720 Issue: 2 - 14/10/09