Troubleshooting Guide

19

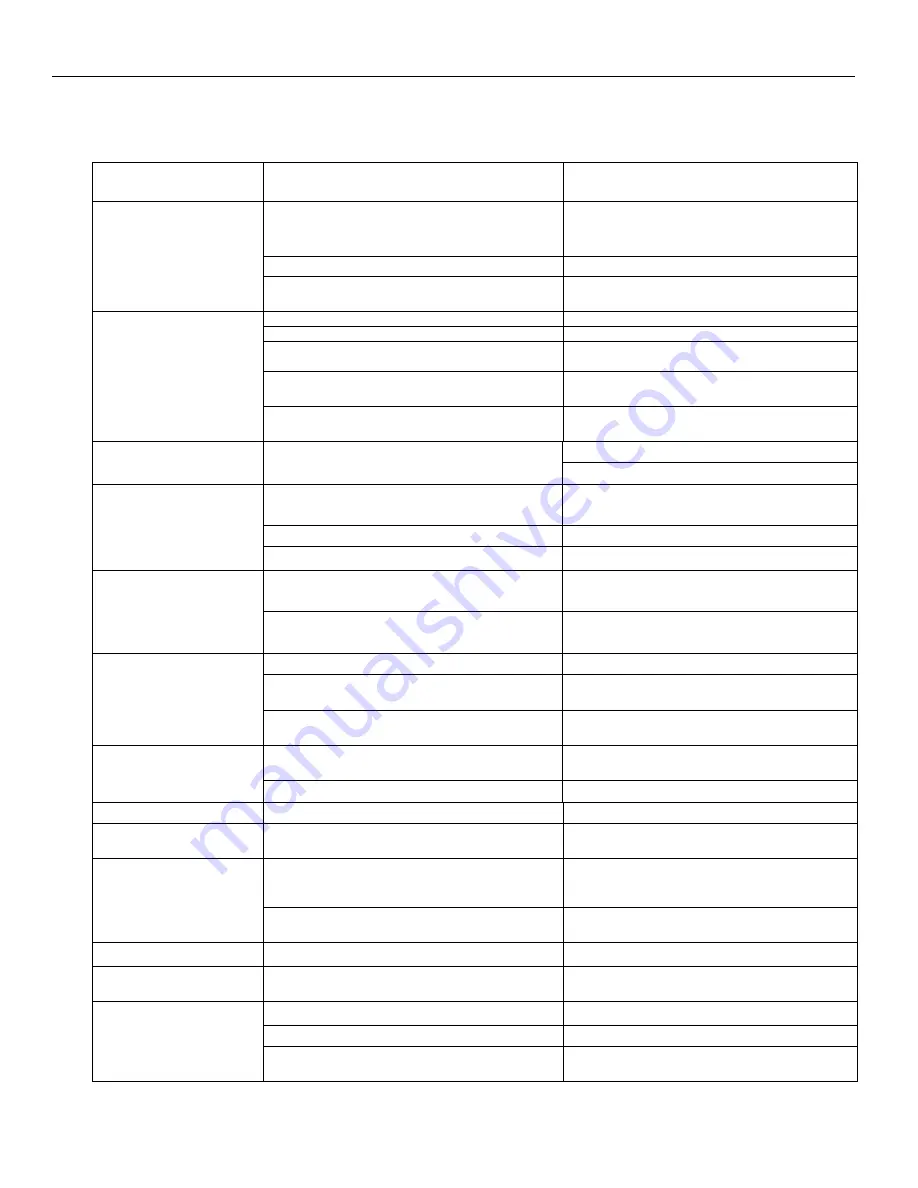

PROBLEM

POSSIBLE CAUSE

SOLUTION

Pressure not released from rollers after machine was shut

down. The roller has an indentation where the two

rollers stayed in contact with one another.

Run machine for one or two hours with the pressure

on.

Horizontal lines may occur for the same reason.

Clean rollers with straight alcohol.

Coating is uneven

-or-

Horizontal lines are visible on

output.

If horizontal lines persist, roller may have been

permanently damaged.

Replace roller.

Rollers are not clean.

Clean rollers.

Lacquer level is too low.

Add lacquer to the correct level.

Lacquer is deteriorating (due to old age or because it has

been diluted with water).

Replace old lacquer.

Lacquer is too thick.

Restore lacquer to normal viscosity by adding a mixture

of alcohol (20%) and water (80%).

Coating is uneven

-or-

Vertical lines are visible on

output.

Lacquer is too thin

Run coating in machine with humidity dial on “0” until

coating reaches desired thickness (35-55 seconds).

Clean rollers with straight alcohol.

Random spots or marks on

output.

Dirt or dried lacquer may be stuck to the rollers. Lacquer

may have dirt in it.

Filter lacquer with paint strainer or fine wire filter.

Scraper tension is not enough.

Increase scraper tension (adjust scraper tension screws).

Scraper blade may be worn or have nicks.

Remove and replace scraper blade.

Lacquer appears on back of

image.

Scraper blade may have lacquer built up on blade.

Clean blade with alcohol.

Fans not running or defective.

Inspect fan operation and if faulty, call Technical

Service.

Prints not exiting machine.

Shutter is not open.

Open shutter, and if necessary remove jammed images

by running unit in reverse.

(Run) speed is too slow.

Increase speed.

Coating is too thin.

Run coating in machine with humidity dial on “0” until

desired viscosity is reached (35-55 sec).

Prints sticking to rubber

coating roller (common with

inkjet paper).

Set screws in gears may have come loose.

Tighten set screws making sure one set screw is on flat

side of shaft.

Not enough scraper blade tension.

Increase scraper blade tension (adjust scraper blade

screws-see page 16)

Prints wrapping around top

steel roller.

Run speed is too slow.

Increase speed.

Laminator does not turn on.

No power.

Verify that power cable is not loose.

Power switch fails to set.

Verify that the main power switch is in the “ON”

position.

Dried lacquer accumulating on roller brackets.

Clean unit. Remove and clean rollers and roller

bushings thoroughly. Inspect and clean roller brackets,

insuring there is no lacquer build-up.

Silicone roller(s) not turning.

Set screws in gears have come loose or backed out.

Tighten set screws making sure one set is on flat side of

shaft.

Motor will not run.

Blown fuse.

Check the 2.5A fuse and replace if blown.

Knocking sound or roller

hesitation.

Loose belt tension.

Remove top cover and check belt tension (should not

have any slack) Tighten is needed.

Bad connection from power source.

Ensure connection is made to nebulizer and fan.

Low water level.

Ensure 1 gallon jug is full with distilled water.

Low level light staying on.

Float directly on nebulizer may be stuck.

Free float in nebulizer to allow float to move freely up

and down.