Installation

14

02.00 | FT-AXIA 80 EtherCat | Assembly and operating manual | en | 1009369

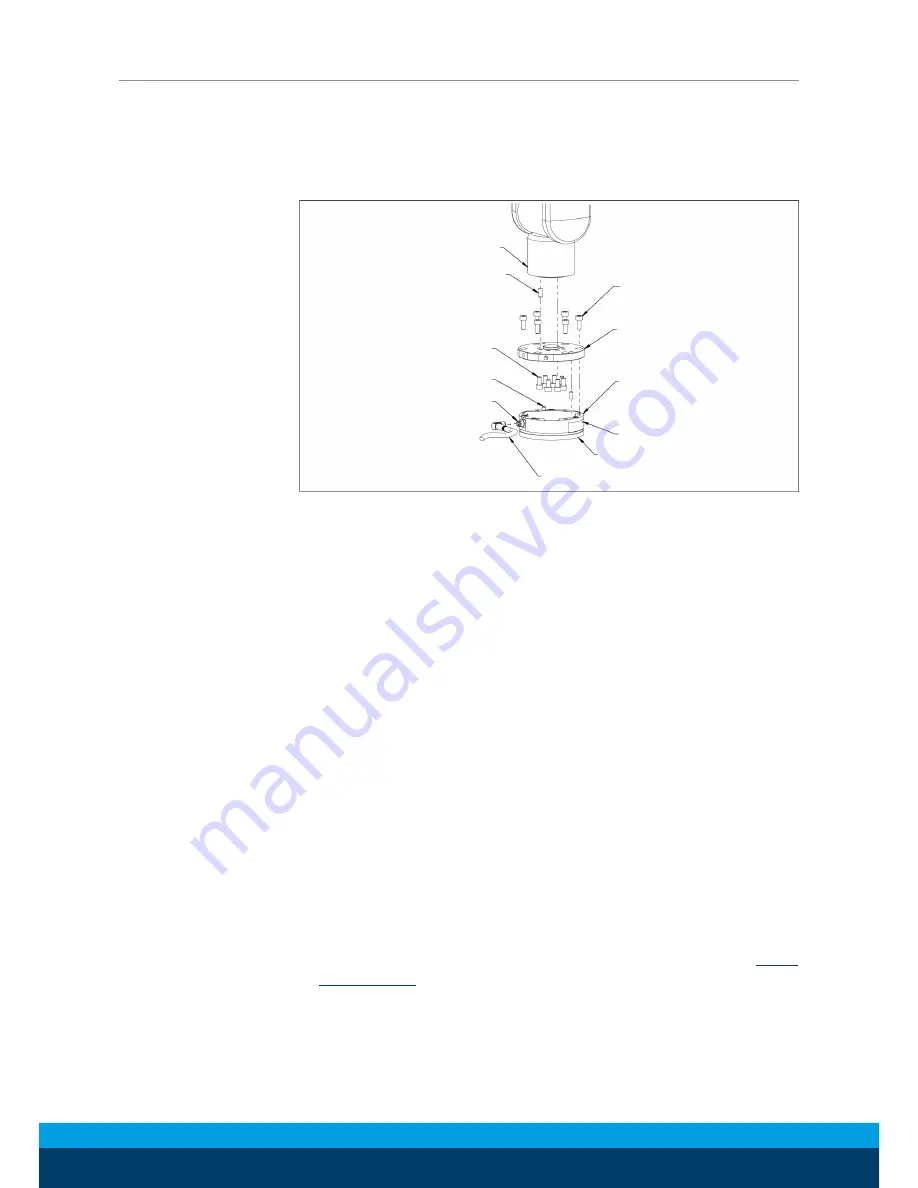

4.3 Installing the Sensor to the Robot

Tools required: 4 mm hex wrench, torque wrench

Supplies required: Clean rag, Loctite 242® or fasteners with pre-ap-

plied adhesive

Robot

Dowel Pin

(Customer Supplied)

M5 Socket Head

Cap Screw (6x)

Dowel Pin (2x)

Power and EtherCAT

Connection

Power and EtherCAT cable

(Customer Supplied)

Mounting Side to Customer Tooling

Axia 80

Mounting Side

to Robot or Interface Plate

Interface Plate (example)

Mounting Fasteners

(Customer Supplied)

Ø

To attach the mounting adapter plate to the robot, remove the

six M5 socket head cap screws that secure the adapter plate to

the mounting side of the Axia80 sensor.

Ø

Ensure the mounting surface of the mounting adapter plate and

robot are clean and free of debris.

Ø

If applicable, secure the mounting adapter plate to the robot

arm with customer supplied fasteners and dowel pin.

Ø

M5x 12 socket head cap screws class 12.9 (6x), with pre-applied

adhesive require no additional Loctite for initial installation.

When reusing fasteners, always apply Loctite 242 to the M5

socket head cap screws.

Ø

Using a 4 mm hex wrench, secure the sensor to the mounting

adapter plate with the six M5x 12 socket head cap screws, class

12.9. Tighten to 9 Nm.

Ø

Once the sensor is installed on the robot, the customer tooling

or tool interface plate can be installed.

NOTICE! The tool must not touch any other part of the sensor

except the tool side; otherwise, the sensor will not properly

detect loads.

Ø

Connect a power and EtherCAT cable from the sensor’s connec-

tion to the customer application.

Ø

Properly restrain and route the power and EtherCAT cable

Rout-

ing the Cable

[

}

12].

Ø

After installation is complete, the sensor is ready for normal op-

eration.