I/2

ES 150-2,5 / ES 150-5

GB

Table of contents - Part 1

1.1 Scope of delivery

– Random orbit sander

– Sanding pad

– U-disc

– Assembly key ( 1 x )

– Instruction manual

1.2 Conventional use

The compressed air tool is an industrial tool

suitable for:

Sanding wood, plastic, metal, paint / clear

coats, filler and similar materials.

Any other type of use is considered contrary

to the intended use.

1.3 Technical data

see Figure A

1.4 Symbols and their meaning

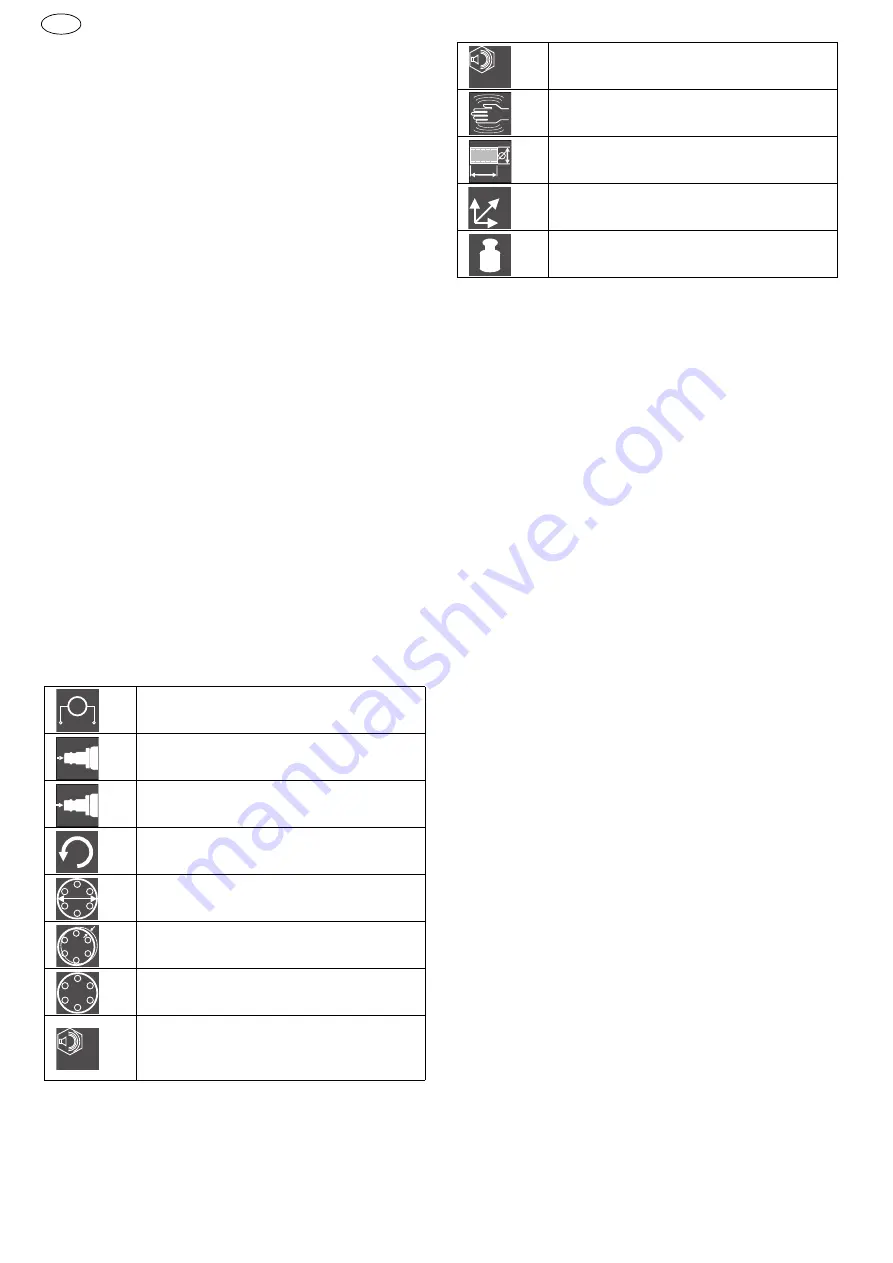

1.5 Components

1.6 Commissioning

Caution:

Depressurise the unit!

Assembly:

1. Insert the sanding pad (item 05) into the

tool holder (item 04) (Fig. 2a/3a).

2. Place the assembly spanner on the tool

holder (Fig. 2a/3a).

3. Screw on the sanding pad and tighten

(Fig. 3a).

4. Remove the assembly spanner.

1.7 Attaching sanding accesso-

ries

Caution:

Depressurise the unit!

L

Perform your work using suitable com-

mercial self-adhesive sandpaper. Make

sure that the diameter and hole positions

on the sandpaper match those of the

sanding pad.

Press the self-adhesive sandpaper onto the

sanding pad (item 05).

1.1

Scope of delivery ......................

2

1.2

Conventional use ......................

2

1.3

Technical data ..........................

2

1.4

Symbols and their meaning ........

2

1.5

Components.............................

2

1.6

Commissioning .........................

2

1.7

Attaching sanding accessories.....

2

Power [kW]

Air consumption [l/min]

Max. permissible pressure [bar]

Rotational speed [rpm]

Grinding disc (diameter) [mm]

Sanding stroke [mm]

Number of holes

Sound pressure level L

pA

(at dis-

tance of 1 m) as per EN ISO

15744 [db(A)]

P

Q

p

max

n

Z

L

pA

Sound power level L

WA

according

EN ISO 15744 [dB(A)]

Vibrations as per ISO 8662

[m/s

2

]

Recommended hose diameter

(inner) at L= 10 m [mm]

Overall dimensions: width x

depth x height [mm]

Weight [kg]

01 Plug nipple

02 Trigger lever

03 Air regulation

04 Tool fitting

05 Sanding pad

11 Exhaust air guide

12 Extractor connector

L

WA

10 m

H

T

B

m