Instructions for Use

– SCHMIDT

®

Flow sensor SS 20.260

Page 9

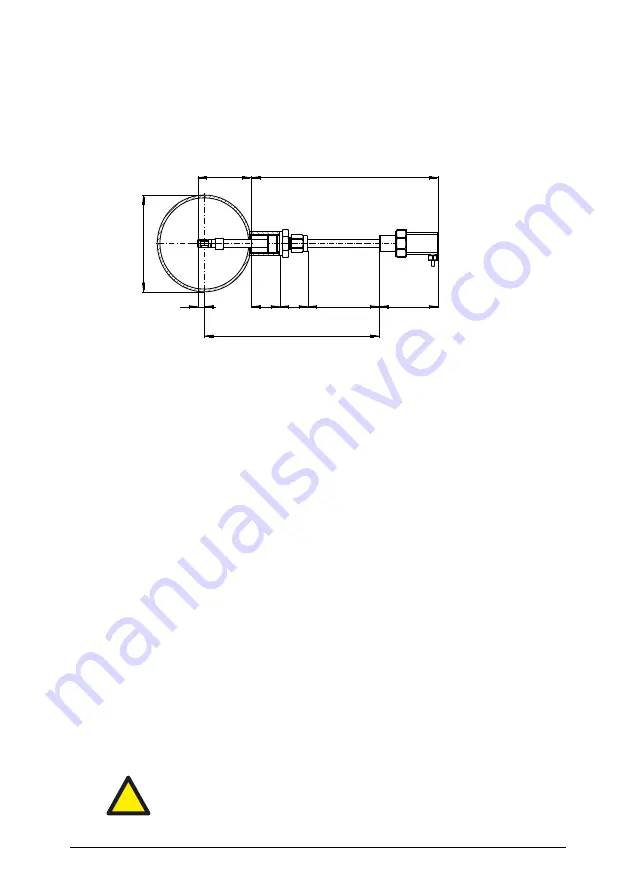

Mounting with a through-bolt joint

The sensor is installed using a special through-bolt joint (517206). Nor-

mally, a sleeve is welded as a connecting piece onto a bore in the medium-

guiding pipe, in which the external thread (G½) of the through-bolt joint is

screwed (see Figure 3).

Figure 3

L

Sensor length [mm]

D

A

Outer diameter of the pipe [mm]

SL

Length of the weld-in sleeve [mm]

E

Sensor tube setting length [mm]

AL

Projecting length [mm]

MID

Minimum immersion depth [mm]

Bore a mounting opening in a pipe wall.

Weld connecting piece with an internal thread G½ resp. Rp½ centered

above the mounting opening of the pipe.

Recommended length of sleeve:

15 ... 40 mm

If necessary wrap thread of through-bolt joint with common sealing

tape, for example made of PTFE.

Screw thread of through-bolt joint by hand into connecting piece then

tighten it firmly with a fork wrench (SW27).

Remove spigot nut of through-bolt joint and extract both seal halves.

Remove protective cap from sensor tip and attach spigot nut on sen-

sor probe.

Insert probe in threaded part of through-bolt joint, attach seal halves

and screw on spigot nut manually to such an extent that the sensor

probe can be inserted without jamming.

In case of a longer sensor probe push it partly into the pipe as re-

quired.

Always avoid bending of the probe tube during screwing.

L

AL

66

SL

32

MET=20

8

E

D

A

!

MID = 20