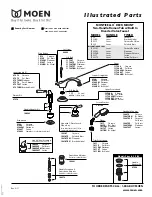

ON THE FLOOR INSTALLATION

Page 6 of 10

GB1-CT Installation Guide

3

Calibrate Flow Control

Note to Plumbing Inspector

This

interceptor includes certified internal flow

control and does not require a dedicated

“Flow Control Vent” (air intake).

3c1

3c2

Slide flow control cartridge into top of inlet diffuser and rotate

clockwise until cartridge drops onto flow control retainer pins.

Continue rotating clockwise until pins are fully seated.

flow control

retainer pin

cartridge

receiver slot

3a1

3a2

Rotate flow control cartidge counter-clockwise

to release and remove from inlet diffuser

Figure 1

OR

OR

OR

A

A

• If dimension is 5 feet or less

go to Step 4

.

• If dimension is greater than 5

feet

follow Steps below

.

3b

Attach the 15 GPM Flow Control

Cartridge Extension using PVC

primer/cement.

Make sure

extension is fully inserted into

the cartridge and hold both

components firmly together

(until cement grabs) to

prevent push-out.

15 GPM