13

45° diagonal cutting (Fig. 8)

1

Set angled stop (6) to 45°

2

Carry out cutting as described.

45° longitudinal cutting, (Fig. 9)

1

Loosen the star knob screw (E) on both sides

2

Slant guide rail (8) at the left to 45° of the angle

scale (18).

3

Tighten the star knob screw (E) again.

4

Perform cutting as described.

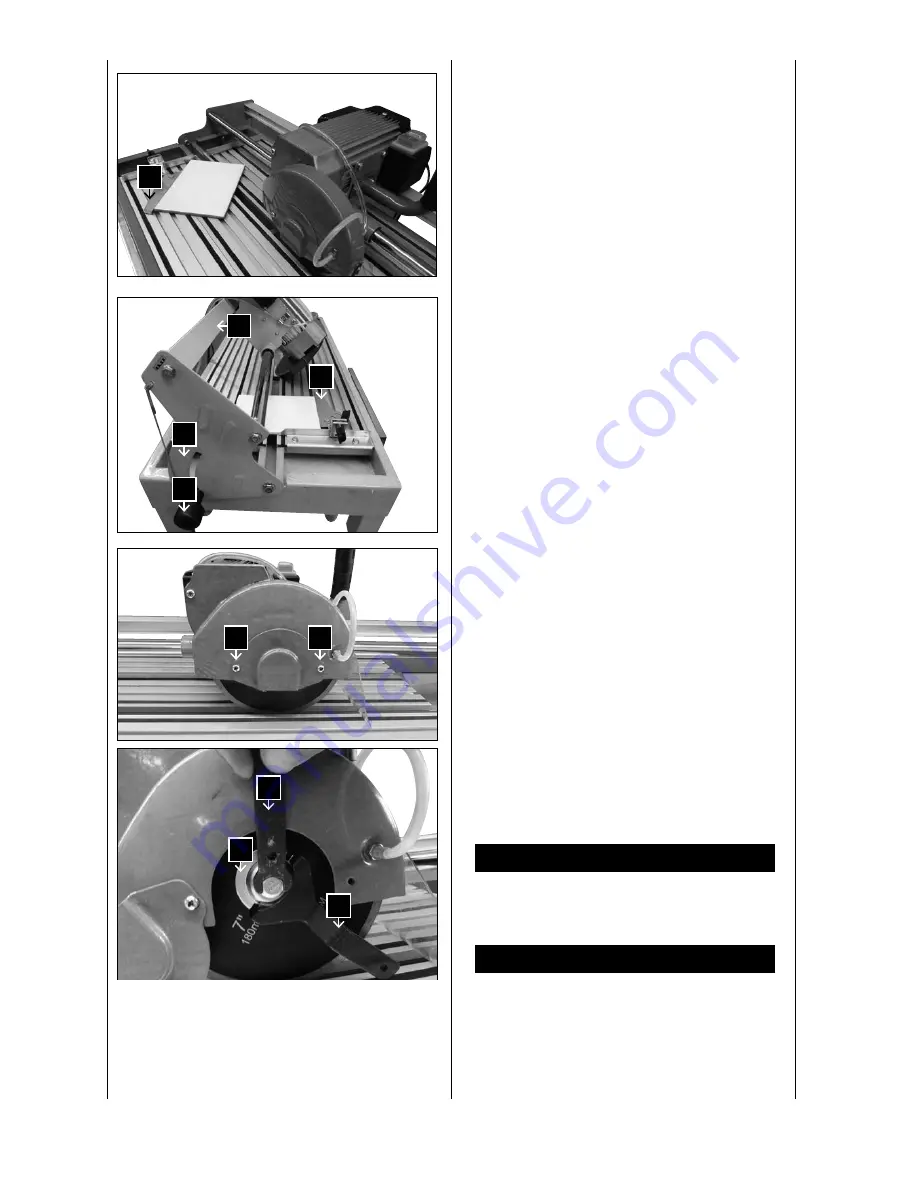

Changing diamond cutting disc (Fig. 10- 11)

Caution! Disconnect power plug

1

Loosen the 2 bolts (F) and take out the saw blade

protection (20). (Fig.10)

2

Place the wrench (21) on the motor shaft and keep

it there.

3

Loosen the flange nut in the running direction of the

cutting disc (10) with the wrench (22).

4

Remove the outer flange (23) and cutting disc (10).

(Fig.11)

5

Clean the supporting flange carefully before installing

the new cutting disc.

6

Insert the cutting disc in the reverse sequence and

tighten it.

Caution:

Pay attention to the running direction of the cut-

ting disc!

7

Reinstall the saw blade protection (20).

Transport

Caution! Disconnect power plug

To transport the machine, set the machine head in front

and engage the locking pin (13) (Fig.5)

m

Electric connection

Check electric cables regularly for damage. Ensure that

during the check, the connecting cable is not connected

to the mains.

Electric connecting cables must conform to the common

VDE- and DIN provisions. Only use connecting cables

with the H 07 RN designation.

Keeping a copy of the type designation on the connecting

Fig. 8

6

Fig. 9

6

8

18

E

Fig. 10

F

F

Fig. 11

21

22

23

Содержание FS85000

Страница 3: ...GB Tile cutting machine 4 17...

Страница 20: ......