Sauter GmbH

Ziegelei 1

D-72336 Balingen

E-Mail: [email protected]

Tel: +49-[0]7433- 9933-199

Fax: +49-[0]7433-9933-149

Internet: www.kern-sohn.com

Instruction Manual

HN-D

HN-D-BA-e-1213

4

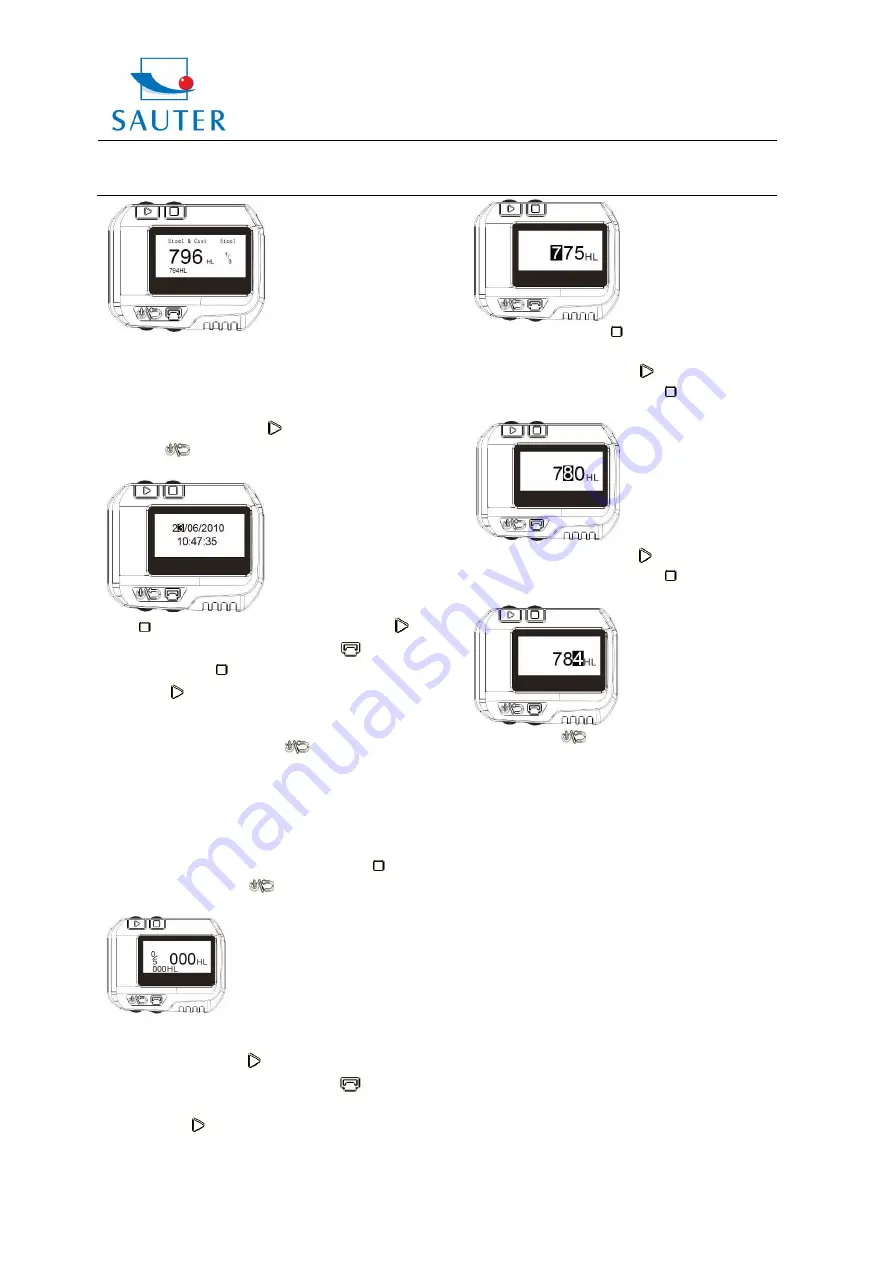

5.3.5 Setting Date and Time

The HN-D has gota built-in real-time-clock. Clock and

calendar have to be adjusted if it is necessary. The

procedure is as follows:

In shut-off mode, the button

has to be pressed and

held, then

has to be pressed for about 3 seconds to

enter the date and time setting mode.

Press

to increase the „day“ from 1 to 31, press

to

decrease the “day” from 31 to 1. Press

to set the

month. Then press

to increase the month from 1 to 12

and press

to decrease the month from 12 to 1. The

same way is used to set the year, hour, minute and

second. In the “second “ set-up process, the setting will be

finished by pressing the button

and the instrument

returns to the measuring mode.

5.3.6 Calibration

Calibration is used to calibrate the measured value (HLD)

of the hardness tester up to the minimum measuring error.

The procedure is as follows:

1. When the instrument is turned off, the button

has to

be pressed and held; then

has to be pressed and held

for about 3 seconds to display the calibration mode.

Now, 5 tests have to be performed on the test block to get

the average value of these values.

2. By pressing the button

, the 5 measured values can

be browsed and by pressing the button

, the error

values can be deleted.

3. If the button

is pressed, it can be started to input the

value written on the test block: Primary, the „hundred“ bit

has to be set (see illustration below).

4. By pressing the button

, it can be increased from 0 to

9 to set the “hundred” bit.

5. By pressing the button

, the „ten“ bit will be

highlighted. By pressing the button

, it can be increased

from 0 to 9 to set this bit.

6. By pressing the button

, the “one” bit will be

highlighted. By pressing the button

, it can be increased

from 0 to 9 to set this bit.

7. If the button

is pressed, the instrument returns to

the measurement mode and the calibration is finished.

Note: 1. Before the first use, the hardness tester has to

be calibrated on the test block.

2. The impact direction has to be set straight down.

5.4

The Format of Memory Data

The data (such as hardness value, scale , sample material

and impact direction, time, date etc.) will be saved in the

memory automatically after each individual impact. HN-D

can store 500 data. When the test times are more than

500, the last data will be stored in the 1

st

position and the

first dat will be erased, simultaneously the position of other

data will be automatically moved into the lower position.

5.5

Backlight

LED backlight is used for poor light conditions. If there is

no impact performed or any key operation has taken place

in 3 seconds, the backlight will be turned off automatically.

When testing continues or any key is pressed, the

backlight will be turned on again.