11/99

7 - 10

DS 3.401

COMMISSIONING

WARNING -

WHEN ACTUATOR IS OPERATING BEWARE OF TRAPPING

FINGERS ETC.

BEFORE SWITCHING ON POWER SUPPLY:

ALM and ALX Actuators

1.

Check that all control equipment is correctly located and fitted.

2.

Check ambient temperature conditions.

3.

Check that actuator has been correctly assembled to valve, up to

the stage when electrical power is called for.

4.

Remove terminal cover and check that all control circuit wiring is

correct and in accordance with the overall control system wiring

diagram. Check that the electrical supply voltage is correct.

5.

Note: Wiring errors not only cause malfunctions; they may also

damage controllers and/or actuators.

6.

Replace terminal cover. Set manual override push button to 'Auto'

position.

7.

Now switch on power supply.

8.

Check that the actuator functions correctly by operating the

controlling switch or adjusting the controller set value above and

below the temperature (or humidity) currently existing at the sensor

(or simulated). This must be within the scale limits.

If the actuator forms part of a multi-stage system in which several

actuators operate in sequence, wait until the appropriate stage is

reached.

9.

Whilst checking actuator travel over full stroke of valve, run

actuator to fully retracted position. Select self-adhesive indication

scale to match valve stroke, from set of four scales provided. Fix

scale along outside edge of actuator mounting bracket, in position

where it will be most clearly visible, lining up top edge of anti-

rotation plate on actuator spindle with position '0' on scale (Fig.7).

10. If auxiliary switches are fitted, remove terminal cover to check for

correct operation and switching functions. Replace terminal cover.

ALM, ALX WIRING PRECAUTIONS

WARNING -

ALM ACTUATORS AND AUXILIARY SWITCHES (WHERE FITTED)

ARE AT MAINS POTENTIAL. OBSERVE LOCAL WIRING

REGULATIONS, EARTHING REQUIREMENTS AND ALL USUAL

SAFETY PRECAUTIONS.

* When wiring to BAS outstations refer to the appropriate outstation

data sheet for the wiring precautions.

For longer lengths, increase cable size and observe max. resistance.

Screen feedback wiring, or use MICC or run in a separate conduit,

when applicable.

Caution

Do not connect ALM or ALX actuators in parallel.

ALE Actuators

BEFORE SWITCHING ON POWER SUPPLY:

•

Check that all control equipment is correctly located and fitted.

•

Check ambient temperature conditions.

•

Check that actuator has been correctly assembled to valve, up to the

stage when electrical power is called for.

•

Remove terminal cover and check that all control circuit wiring is

correct and in accordance with the overall control system wiring

diagram. Check that the electrical supply voltage is correct.

Note: Wiring errors not only cause malfunctions; they may also

damage controllers and/or actuators.

Setting the Actuator

The following instructions MUST be followed to initially set the actuator

stroke and each time the actuator is transferred to a different valve.

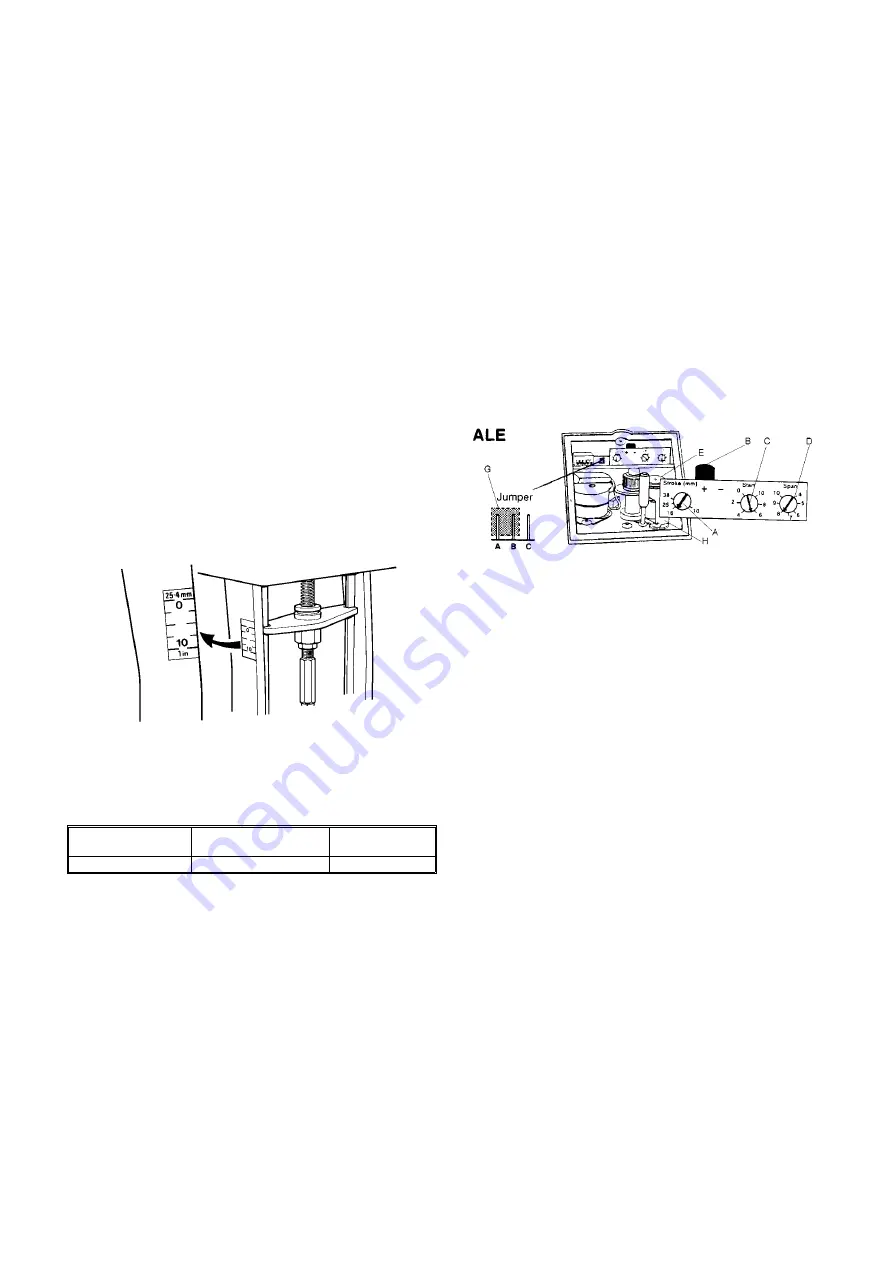

Set all adjustments as follows (see Fig.8):

1.

Set manual override push button to 'auto' position.

2.

Remove wire from terminal 9, ensuring a 0Vdc supply.

3.

Switch on 24V supply. The actuator drive screw will run until it is

fully retracted (position 0) operating its limit switch.

4.

Wait until the drive screw has stopped moving before continuing.

5.

Loosen the pot fixing screw 'H'. By sliding the pot assembly

towards you, disengage gear 'E' from the main drive shaft. Turn the

pot gear 'E' by hand in the anti-clockwise direction (when viewed

from above) until the end stop is reached. Gently slide the pot

assembly back into position so that the pot gear 'E' engages with

the main drive shaft. Do not apply too much force in meshing the

gears as over pressure will result in reduced life. Re-tighten the

location fixing screw 'H'.

6.

Check that the voltage between terminal 7 and 11 is 0.1V ±100mV.

7.

Reconnect wire to terminal 9.

8.

Adjust controller set value to give 10Vdc output.

9.

Check that the Voltage between terminals 7 and 9 is approximately

10Vdc.

10. Change the 'START' setting from '10' to '0'. The actuator drive

screw will now run until it is fully extended (position 10).

11. Wait until the drive screw has stopped moving before continuing.

12. Adjust the 'STROKE' setting in an anti clockwise direction until

Voltage measured between terminals 7 and 11 is 9.9V ±100mV.

13. Select and fix the appropriate self-adhesive stroke indication label

to the actuator bracket. The relevant stroke length can be found on

the appropriate Satchwell data sheet for the valve being used.

14. Re-set 'START', 'SPAN' and 'DA/RA' adjustments as required, to

suit control system. DO NOT alter 'STROKE' setting. Re-check

operation by adjusting controller set value so that actuator runs to

position '0'. If limit switch does not operate, adjust 'START' setting

very slightly anti-clockwise for 'DA' switch mode (clockwise for 'RA'

switch mode) until limit switch does operate. Now adjust controller

set value so that actuator runs to position '10'. If limit switch does

not operate, adjust 'STROKE' setting very slightly clockwise for DA

and anti-clockwise for RA until limit switch does operate. Re-adjust

controller set value as required, to suit control system.

Wiring from actuator

to controller*:

Max. length of 1.5mm²

cable unscreened

Max. resistance

per conductor

24V/240V~ Supply

100m

5

Ω

Fig.7

Adjustment

Setting

START 'C'

10

SPAN 'D'

10

STROKE 'A'

max. (fully clockwise)

DA/RA SWITCH 'B'

+ (DA)

HYSTERESIS JUMPER 'G' A-B or B-C

Fig.8