18

English

!

Pump Down

"

When relocating or disposing of the Air Conditioner, request

this service from the dealer where the unit was purchased,

or from an appropriate agent. Perform pump-down as

described below.

What is pump-down?

"

Pump-down refers to recovering the refrigerant gas from the

refrigerant cycle at the outdoor unit. This work must be

performed during cooling operation. The refrigerant gas

cannot be recovered during heating operation.

"

During winter, or if the temperature sensor prevents cooling

operation, perform “forced cooling operation.”

Pump-down procedure

(1) Fully close the spindles at the valves on the narrow tube

side of tubes A, B, C and D. (Refer to Fig. 22.)

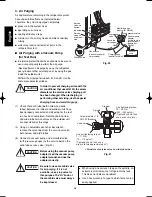

(2) Connect the manifold gauge to the charging port at the valve

on the wide tube side of tube D. Purge the air from the

charging hose. (Refer to Fig. 23.)

(3) Perform cooling operation or forced cooling

operation.

When the pressure at the low-pressure side is 0.15 – 0.2

MPa (0.5 – 1 kg/cm

2

G), fully close the spindles at the

valves on the wide tube side of tubes A, B, C and D, and

immediately stop operation. (Refer to Fig. 23.)

In the winter, the outdoor unit may stop after 5 - 10 minutes

of operation. This is in order to protect the indoor unit heat

exchanger from freezing and does not indicate a problem.

(4) Disconnect the manifold gauge and the inter-unit tubes,

and attach the caps and flare nuts. At this point, pump-

down is completed. (If the caps and flare nuts are not

reattached, there is the danger of gas leakage.) (Refer to

Fig. 24.)

If pump-down is not possible

If the Air Conditioner cannot be operated because of a

malfunction or other cause, use a refrigerant recovery

device to recover the refrigerant.

In order to protect the earth’s environment, be sure to perform pump-down to recover refrigerant

gas without releasing it into the atmosphere.

Fig. 22

(11) Replace the flare nut on the wide tube service port and fasten the flare nut securely with an adjustable wrench or

box wrench. Next, mount the valve cap and tighten it with a torque wrench (the cap needs to be tightened with the

torque of 20 N·m (200 kgf · cm)). This process is very important to prevent gas from leaking from the system.

(12) Test run the air conditioner. (See page 23.)

(13) While the air conditioner is running, apply liquid soap to check for any gas leaks around the service valves or caps.

(14) If there is no leakage, stop the air conditioner.

(15) Wipe off the soap on the tubing.

This completes air purging with a vacuum pump and the air conditioner is ready for actual operation.

Fig. 23

C

D

B

A

Manifold gauge

Wide tube side

Cap

Cap

Cap

Cap

After disconnecting

the inter-unit tubes,

attach the flare nuts

with flare bonnets.

Fig. 24

D

C

B

A

Charging port

Narrow tube side

Close

Close

Close

Close

08-253 CMRV3146EH_OU EN 10/14/08 2:39 PM Page 18