16

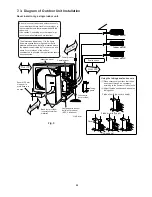

Outdoor Unit

SAP – CMRV2433GJ

CAUTION

Before replacing PCBs, turn off the power and check that all

lamps on the PCB are off before starting work. Electric shock

will occur if work is performed while the lamps are lit.

Electric Shock

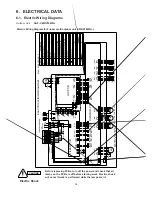

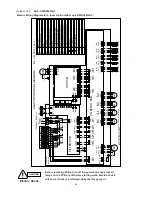

Electric Wiring Diagram for 3-room multi outdoor unit (CMRV2433GJ)

ELECTRIC WIRING DIAGRAM

854

-

2

-

5269

-

181

-

00

-

2

SYMBOLS

DESCRIPTION

CM

FMO

MMV

TH1

TH2

TH3

TH4

TH5

RE1,2

HS

COMPRESSOR MOTOR

FAN MOTOR

MAIN MOTOR OPERATED VALVE

HEAT SINK

BOARD-IN-WIRE

W

THERMISTOR(HEAT EXCHANGER)

THERMISTOR(OUTDOOR TEMP)

THERMISTOR(COMPRESSOR TEMP)

THERMISTOR(ROOM A NARROW PIPE)

THERMISTOR(ROOM A WIDE PIPE)

REACTOR

CONNECTOR

TERMINAL BASE

TERMINAL

SOLDERED TERMINAL

5

4

3

2

1

CN38

MVB

2

2

1

1

BLK

DC280+

W

AC200

DC280

-

AC200-L1

5

CN01

1

3

(WHT

)

DC280

W

WHT

GRY

G1

W

2

1

4

3

2

1

5

4

3

2

1

37

5

1

3

1

COMP

COIL

/GAIKI

CN19

CN13

CN36

MMV

CN09

FMO

CN16

FMOTH

BLK

GRY

BRN

MVB

CN24

ATH

1

23

MMV

FMO

4

6

WHT

W

GRN/YEL

FC2

FC1

GRN

/YEL

GRN

/YEL

(RED

)

( BLK

)

6

MVA

MVA

CN37

1

2345

+

YEL

YEL

WHT

RED

YEL

YEL

BRN

BLU

YEL

HIC PCB

D

TR

G2

W

W

L1

L2

WHT

BLK

1

TH3

6

GRY

ORG

MC02

MC01

+

GRY

3

(WHT

)(

WHT

)

(WHT

)

(BLK

)

(WHT

)(

BLK

)

C0

BD

BRN

YEL

WHT

ORG

BLU

RED

RED

YEL

BRN

BLU

ORG

WHT

TH1

TH2

TH4

TH5

CN22

BTH

1

234

YEL

YEL

YEL

(RED

)

TH6

TH7

CN20

CTH

1

234

YEL

YEL

YEL

(BLU

)

TH8

TH9

BLK

YEL

YEL

BLK

CN29

AC200-L2

W

W

CN21

(RED

)

PRY

PRY

(WHT

)

BLK

BLK

3

3

1

1

CN08

(WHT

)

CT

CT

(WHT

)

BLK

BLK

2

2

1

1

(WHT

)

BLK

WHT

5

5

4

4

CN23

PAM

PAM

(WHT

)

BLK

WHT

7

7

6

6

TERMINAL BASE

(3P

)

BRN

SI

5

1

3

(WHT

)

CN35

9

7

ORG

HS

FILTER PCB

2

2

BLK

1

1

BLK

CN03

(WHT

)

HIC3

HIC3

CN18

(WHT

)

11

11

CN02

BLK

10

10

7

78

8

BLK

BLK

BLK

(WHT

)

HIC2

HIC2

CN30

4

45

5

BLK

BLK

(WHT

)

1

12

2

BLK

10

10

9

9

8

8

CN01

7

7

5

56

6

(WHT

)

HIC1

HIC1

CN34

3

34

4

BLK

(WHT

)

1

12

2

BLK

WHT

HIC

-

HIC+

+

+

GRY

YEL

HIC

-

W

W

HIC+

RE2

INDOOR UNIT A

W

V

CONTROL PCB

RED

THERMISTOR(ROOM B WIDE PIPE)

THERMISTOR(ROOM B NARROW PIPE)

TH6

MECHANICAL VALVE

MVA MVC

TH7

D

BD

BRIDGE DIODE

DIODE

TR

TRANSISTOR

C0

OPERATION CONDENSER

12

312

312

3

2

1

TERMINAL

BASE

(12P

)

GRN/YEL

GRN

/YEL

BLK

WHT

GRN

/YEL

BLK

GRN

/YEL

12

4

INDOOR UNIT B

4

2

1

INDOOR UNIT C

4

2

1

1 AC220V

240V

EARTH

CM

BLU

WHT

GRN

/YEL

U

+

+

TH9

THERMISTOR(ROOM C WIDE PIPE)

THERMISTOR(ROOM C NARROW PIPE)

TH8

RE1

RE2

RE1

WHT

WHT

FC1,2

FERRITE CORE

WHT

BLK

BLK

WHT

BLK

RED

WHT

BLU

WHT

(RED

)

PNK

YEL

YEL

YEL

BLK

BLK

BLK

BLK

BLK

BLK

BLK

WHT

BLK

YEL

YEL

WHT

WHT

RED

BLU

ORG

YEL

BRN

(BLU

)

6

MVC

MVC

CN39

1

2345

MULTIPLE INDOOR UNITS

COOLING ONLY OUTDOOR UNIT FOR THREE-ROOM