10. Crankcase/Crankshaft

10-2

Maintenance Information

y

This chapter concerns disassembly of the crankcase for repair purpose.

y

Before disassembling crankcase, except removing engine firstly, following components must be

removed too.

y

Carburetor (chapter 10)

y

Oil pump (chapter 3)

y

Reed valve (chapter 10)

y

Driving belt (chapter 7)

y

Alternator (chapter 6)

y

Cylinder head/cylinder/piston (chapter 5)

y

Except above components are needed be removed, when disassembling L crankcase, following

components must be removed too.

y

Final driving mechanism (chapter 8)

y

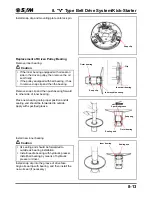

When assembling both crankcase and crankshaft, it has press the inner ring edge of the crankshaft

bearing to push the crankshaft into the crankcase hole by using the specified service tools. The old

bearing onto the crankshaft has to be removed. Then install a new bearing onto the crankshaft on the

crankcase side. Oil seal has to be replaced with new one after assembled the crankcase.

Item Standard

Lateral clearance of the big end of the connecting rod

─

Radial clearance of the big end of the connecting rod

─

Crankshaft run-out point A

─

Crankshaft run-out point B

─

Torque Values:

Crankcase bolt

0.8~1.2kgf-m

Troubleshooting

Engine noise

1. Worn bearing of connecting rod bog end

2. Bend connecting rod

3. Worn crankshaft bearing

Содержание JET 4R

Страница 1: ......

Страница 38: ...3 Lubrication System 3 6 ...

Страница 106: ...12 Brake System 12 2 Rear Drum Brake System 0 8 1 2kgf m 11 0 13 0kgf m 0 8 1 2kgf m ...

Страница 118: ...12 Brake System 12 14 Notes ...

Страница 134: ...14 Rear Wheel Rear Cushion 14 6 Note ...

Страница 163: ......