Sanosil Q-Jet Advanced

15

5.3

Manual (Standard)

Please read and follow important safety directions on page 6

before use!

•

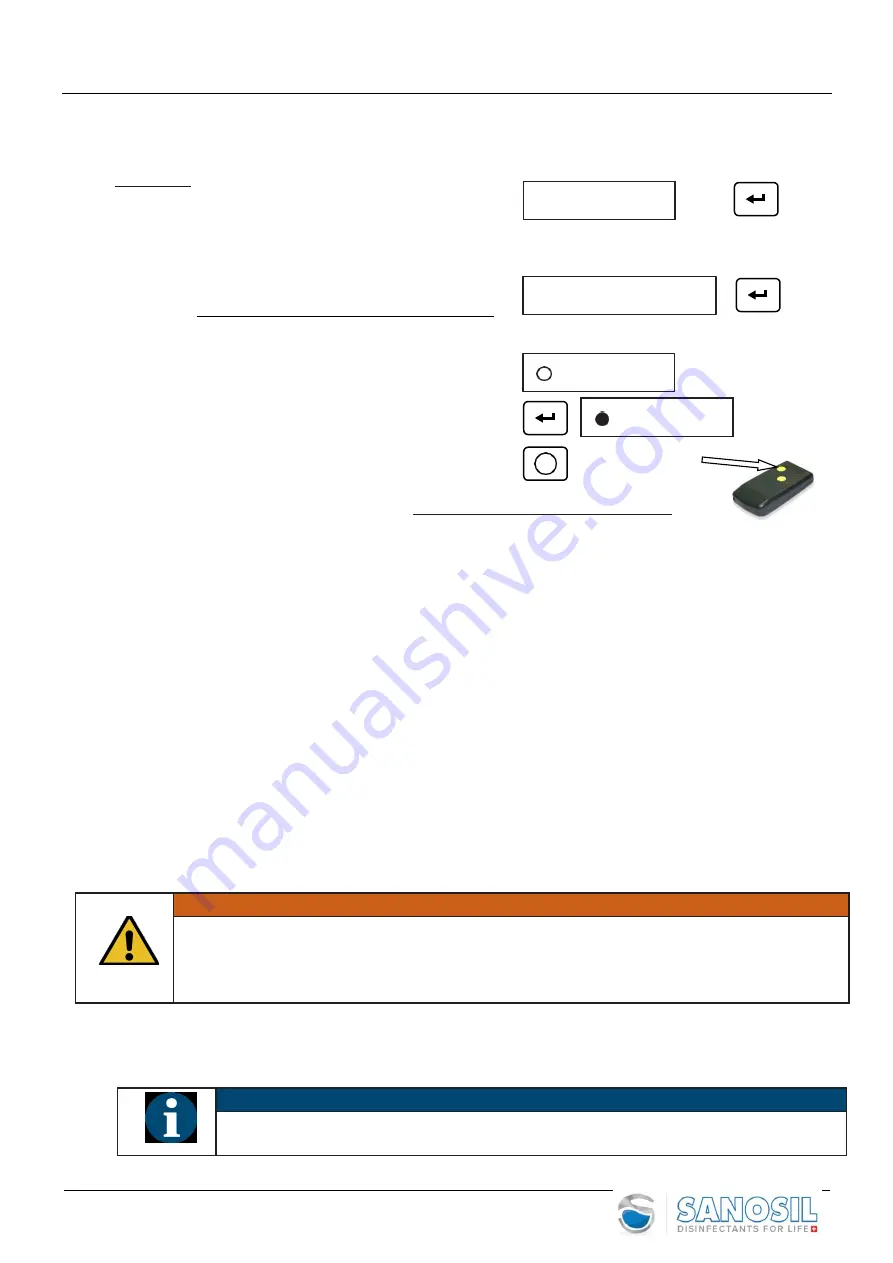

Choose MANUAL and confirm with ENTER

•

Enter

room’s

volume in m

3

(MC: 0-999) and desired

concentration of disinfectant, i.e. ml per m

3

In the room (low risk 8ml / Standard risk 12ml / high risk 16ml)

(CONCENTRAT: 1-50), press ENTER

•

Automatically calculated time is shown

(e.g. MC:83 and CONCENTRAT: 6 = TIME:30:00)

•

Activate process by pressing ENTER

(active = black dot on display)

•

Start disinfection-program by pressing

„

i“

-button

or using the remote control

•

Device will start in 15 seconds (Red LED flashes!)

Please do

immediately leave the room!

•

During the course of the disinfection program the display shows the remaining time (Count-down)

•

At the end of the disinfection program the green LED flashes.

•

Room re-entry minimum waiting-time begins (minimal 120 Minutes)

Recommended minimal “

Nebulization time / Minimum waiting time

”:

0

–

20min/120 min, 20

–

30 min/130min, 30

–

40 min/140min, 40

–

50/min/150min, 50

–

60min and above 160min

•

After the end

of the waiting-time the room can be prepared for re-entry

•

Check with a hydrogen peroxide level sensor that the H

2

O

2

-Level is below 1ppm

•

Open windows and doors for min. 15 minutes, unseal HVAC vents and restart HVAC system to allow increased airflow

circulation in the room. Once a safe ppm level is reached, room can be re-used again.

•

Shortening of waiting time: after a

minimal waiting time of 120 minutes

place a strong dehumidifier in the

middle of the room and dehumidify room for at least 60 minutes or air room by opening a window or HVAC. Use

full protection equipment when placing dehumidifier!

•

When room re-entry is required before treatment process is completed or to perform a H

2

O

2

level check, proper

personal equipment (PPE) including wraparound style goggles; respirator mask (filter class ABE1) filtering hydrogen

peroxide (for example: 3M 4277 or 3M 7500 mask with 6057 filter) and gloves should be worn to safely enter the room.

WARNING!

Risk of injuries!

To prevent injuries do always check H

2

O

2

-Level before entering the room.

When entering room to measure

the H

2

O

2

-Value, do always wear full protection equipment, i.e. protection mask, safety googles and gloves.

The disinfected room can only be entered without protection equipment if the H

2

O

2

-Value is below 1ppm.

Fogging time and consumption (low / normal / high contamination), refer to page 14

•

Tip ON/OFF (3) to switch off device

INDICATION

The liquid inside the device has to be completely emptied (please see chapter 5.11) for

transportation as well as for longer storage of the device!

MC: _83

CONCENTRAT: 6

TIME: 30:00

i

MANUAL

TIME: 30:00