19

MASTER DIE SPRING CHANGE

Master die springs are wearing parts and therefore has to be replace after every 200 000 crimps. To replace

the springs a special tools and -craftsmanship are needed. In order to get the master die springs replaced

contact your SAMWAY representative.

Warning:

Do not use the machine if there are broken or twist springs in the machine. Broken or

twist spring can damage the machine or cause personal injuries.

PRESSURE PIPES

Return cylinders on both sides of the crimping head produce the piston movement backwards and

simultaneous retraction of dies.

Hydraulic pipes to the two cylinders are high-pressure pipes (275 bar). To prevent leakage, be careful not to

damage these pipes and their connectors.

In case you notice leakage in a connector, make sure it is properly tightened. Leaking pipes must be

replaced immediately. DO NOT REPAIR PIPES!

d at the factory during test run.

1. Re-calibrate the crimping diameter with ferrule

(seamless steel tube), Ø 25 mm; wall 2 mm, by

using the die set No 20-19 (20 model) or the die

set 32-19 (32 model).

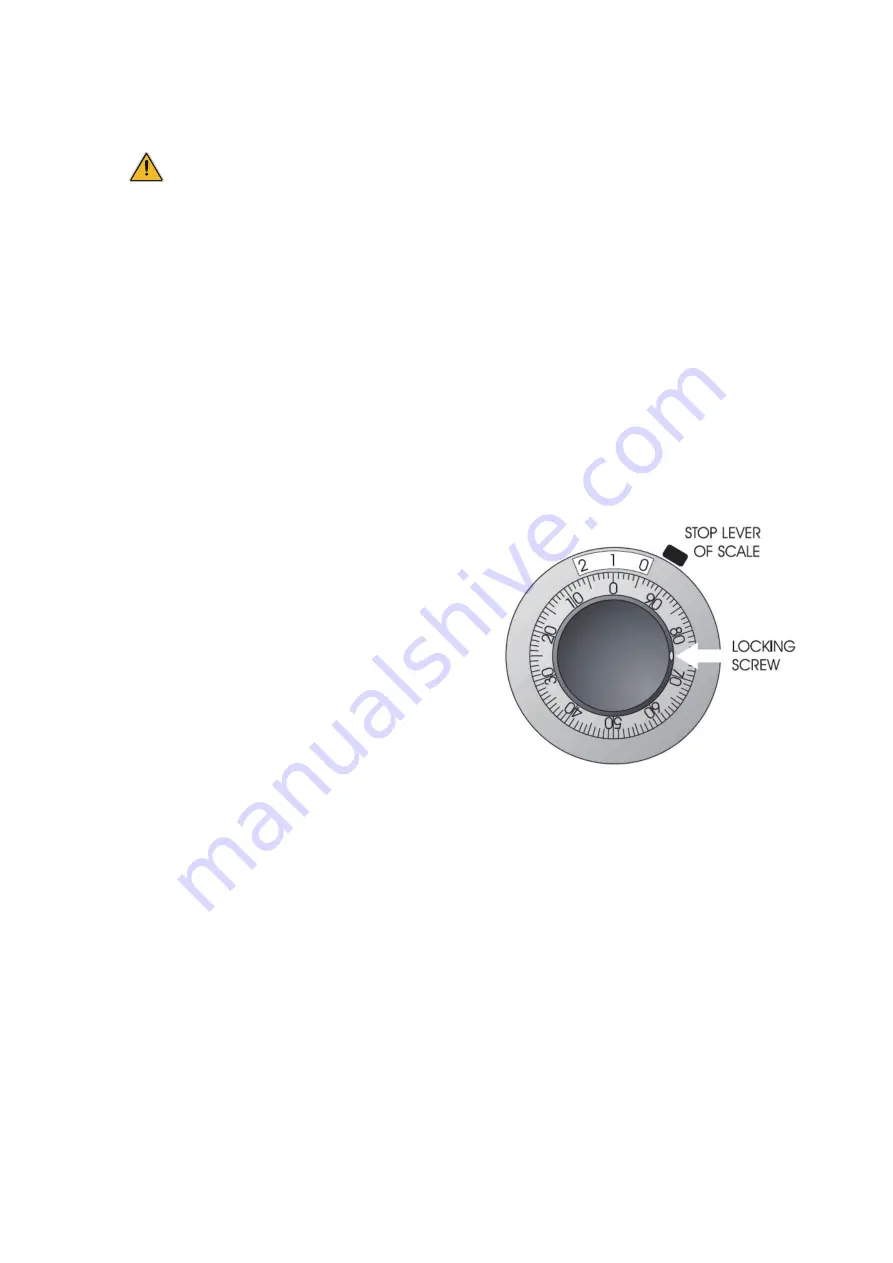

2. Set the dial at 1.0, so that the crimping diameter

will be 20 mm (see the adjacent picture) and lock

the dial. Crimp the ferrule and measure the real

diameter.

3. Remove the control dial knob (avoid to turn the

dial shaft at the same time).

4. Open the dial lock lever and set the real diameter

into it (diameter of ferrule) relock it and install

back.

5. Turn the dial to right diameter and crimp another

ferrule. Now the machine has been calibrated and

the real diameter should be the same than the

diameter which state on the dial. If not, repeat

from point 2 and be more careful when handling

the dial.

6. After the adjustment, the crimping result should be the minimum nominal c rimping diameter of each

die set with the dial at 0.0.

RE-CALIBRATION OF CRIMPING DIAMETER DIAL

NOTE: The crimping diameter dial has been calibrate