Troubleshooting _ 21

4-3. DIAGNOSTIC CODE & CORRECTIVE ACTION

No

Check Code

(Diagnostic code Image)

Description

Corrective Action

1

Hot LED flash

Lid is open when

washer is running.

• Check if a HOT LED flashes during the boiling course.

• As this code occurs because the door is opened, close the

door.

• Since 120V power is connected, check if the power cord is

disconnected or check the insulation status and repair it if

necessary.

• If the main PBA door detection circuit is defective, replace it.

2

Warm LED flash

Communication code

between SUB PBA

and MAIN PBA.

• Check the wire connections and terminal contacts between

the sub and main PBAs.

• Check for disconnected wires.

• Check whether the sub PBA is short-circuited because of

moisture.

• If the main PBA’s communication circuit is faulty, replace it.

3

Eco Warm LED flash

Button is not working

properly.

• Check whether either the Power switch or a tact switch is

continually pressed.

• Check whether the service PBA holding screws are fastened

too tight. If they are fastened too tight, loosen them a little.

• If the main PBA switching IC on/off code has occurred,

replace the main PBA.

• The “Eco Warm” LED flashes if the main relay connections

are incorrect. Check the connections. If there is no flashing in

the connections, replace the main PBA.

4

Cool LED flash

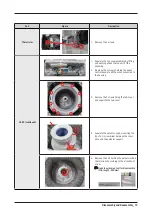

The Water Level

sensor is not working

properly.

• Check the water level sensor terminal connections.

• Check the part code of the water level sensor, because if an

incorrect part is used, an abnormal operation may occur.

(Abnormal operation)

• If the water level sensor is defective, replace it.

• If no problems were found for all of the procedures above,

replace the PBA.

5

Extra High LED flash

Your Washer has tried

to fill but was unsuc

-

cessful.

• If the water supply valve is broken, replace the valve.

• Check if the water supply is blocked due to an alien sub

-

stance in the valve or check if the water is supplied to the

machine. If a problem is found, take the appropriate counter

-

measure.

• Check if the water supply is blocked due to the water being

frozen.

• If the PBA Relay malfunctions, replace the PBA.

6

High LED flash

Your Washer has tried

to fill but has not

reached the proper

water level.

• Since this occurs when an alien substance is in the Draining

Bellows, for natural draining, remove the alien substance.

• If the drain motor is defective, replace the motor.

• Check if the water leaks from the tub connection part.

7

Mid LED Flash

A fault is detected

in the water level

sensor.

• The water level sensor is replaced.