Alignment and Adjustment

Samsung Electronics

2-5

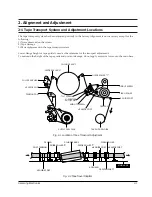

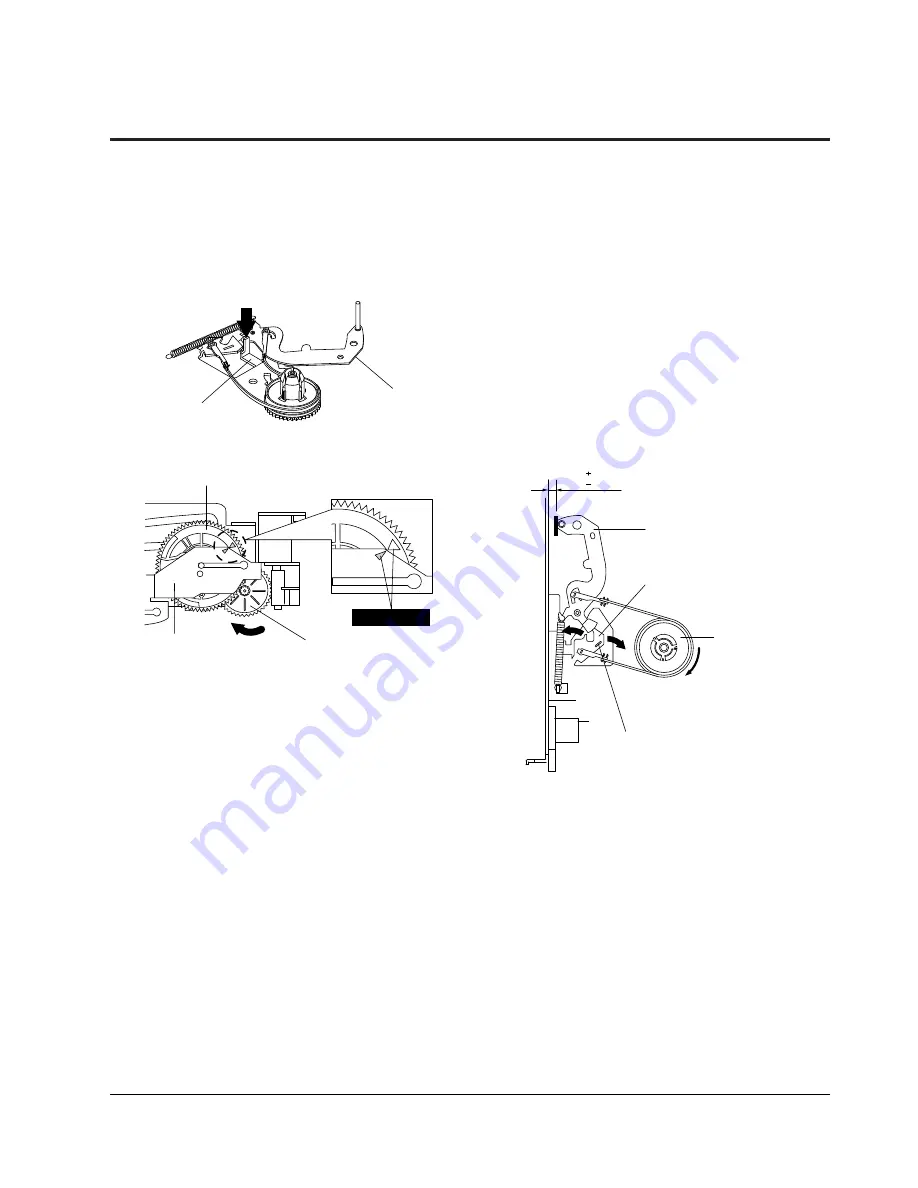

4) As rotating Disk S Reel

Œ

clockwise and the

region of adjusting in the Main Base (in shape of

slit) clockwise or counterclockwise after inserting

screw driver in the slit on Main Base. Adjust the

left end edge of Lever Tension AssÕy

ˇ

to 1.3

+1.5/-0.5mm from the location of mark in the

Main Base.

5) As rotating Disk S Reel

Œ

, double-check the loca-

tion of the left end edge of Lever Tension AssÕy

and the quantity of crossing from mark on Main

Base. (+1.0/-0.5mm)

Counterclockwise

: Torque UP

Clockwise

: Torque DOWN

Back Tension should be 56 ± 15g.cm at inspecting it

with Back Tension Meter.

1.0mm

0.5mm

ˇ

LEVER TENSION ASS'Y

Œ

DISK S REEL

´

ADJUSTING

ADJUSTING SLIT

1.3

Fig. 2-13 Tension Pole and Back Tension Adjustment

1) Remove the holder cassette assÕy and then push

the lever FL Arm-R to the direction of loading.

2) Push the lever tension drive

Œ

in the direction of

arrow. (See Fig. 2-11)

3) Turn the gear worm wheel

´

clockwise so that

ÒTiming PointÓ of the slider FL drive

ˇ

and gear

FL cam

¨

can be aligned (See Fig. 2-12)

Fig. 2-11

Fig. 2-12

¨

GEAR FL CAM

´

GEAR WORM WHEEL

ˇ

SLIDER FL DRIVE

P

TIMING POINT

Œ

LEVER TENSION DRIVE

LEVER TENSION

Note

:

1) Mark on Main Base is located in about 1.3mm

from inside of bending line.

2) Be careful not to deform the region of adjusting on

Main Base up and down at adjusting.

2-4 Location adjustment and Confirmation of Tension Post

Содержание VR400PVR400PC

Страница 16: ...Exploded View and Parts List 3 8 Samsung Electronics MEMO ...

Страница 23: ...Schematic Diagrams Samsung Electronics 5 3 5 1 S M P S 120 Voltage ...

Страница 24: ...Schematic Diagrams 5 4 Samsung Electronics 5 2 S M P S Free Voltage ...

Страница 25: ...Schematic Diagrams Samsung Electronics 5 5 5 3 Power ...

Страница 26: ...Schematic Diagrams 5 6 Samsung Electronics 5 4 Logic ...

Страница 27: ...Schematic Diagrams Samsung Electronics 5 7 5 5 Audio Video ...

Страница 28: ...Schematic Diagrams 5 8 Samsung Electronics 5 6 TM Block Input Ouput ...

Страница 29: ...Schematic Diagrams Samsung Electronics 5 9 5 7 Display ...

Страница 30: ...Schematic Diagrams 5 10 Samsung Electronics MEMO ...

Страница 55: ...2 6 Samsung Electronics Alignment and Adjustment MEMO ...