System Overview

Samsung Electronics

Service Manual

3-1

3

3

3. System Overview

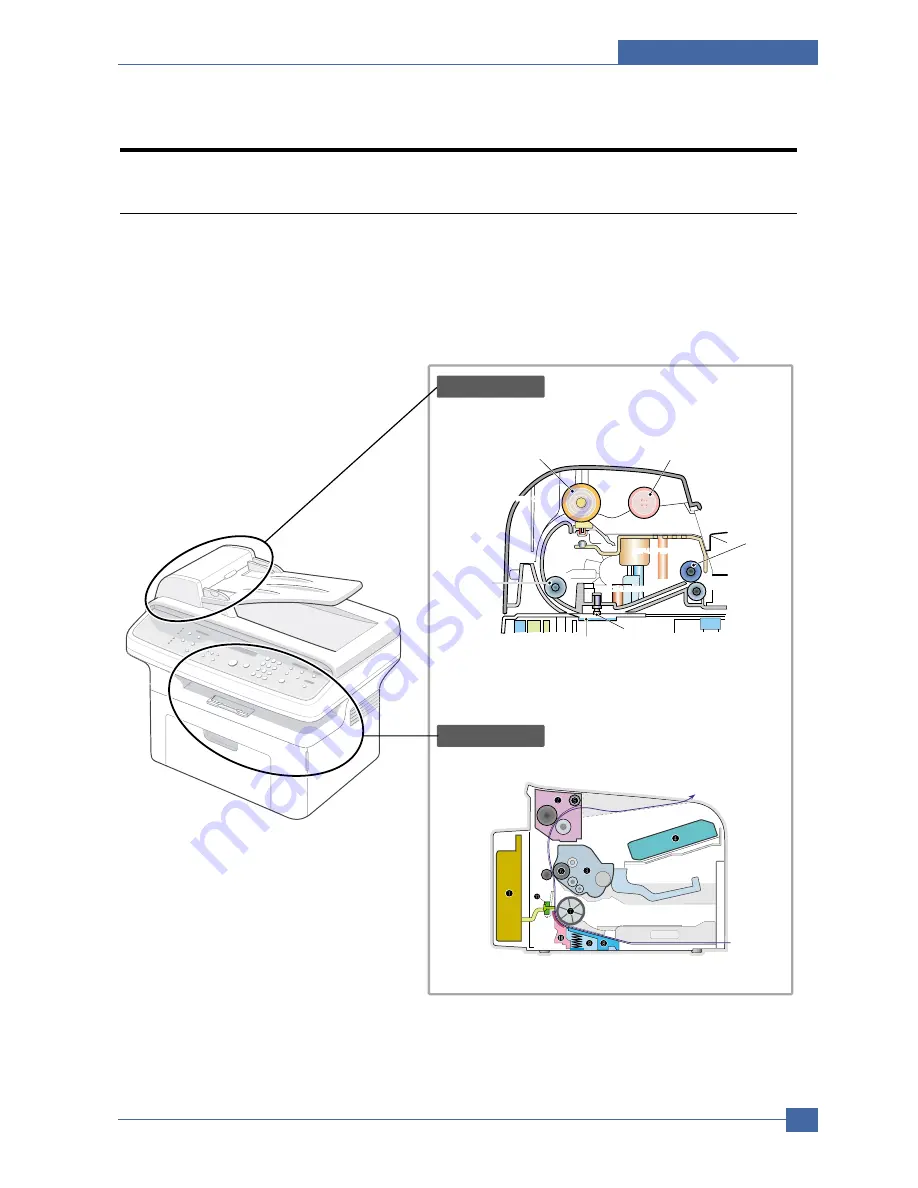

3.1 System Layout

The SCX-4521F/4321 is roughly made up Main Control part, Operation Panel part, Scanner part, Line

Interface part and Power part. Each Part is separated Module which focus on common and standard design

of different kind products. main control part adopting Fax & LBP Printer exclusive Controller is chorus2

CPU(ASIC) and 1 Board. Scanner part is composed of ADF and Platen and is connected with Main by

Harness.

ADF ROLLER

Scanner part

Engine Part

ADF-UPPER

PICK-UP ROLLER

EXIT ROLER

WHITE BAR

ADF-GLASS

FEED ROLLER

SCAN UPPER

SCAN UPPER

SCAN UPPER

ADF-LOWER

COVER OPEN

BIN PATH

Содержание SCX-4321

Страница 47: ...Samsung Electronics Service Manual Alignment and Adjustments 4 15 ...

Страница 127: ...Exploded Views Parts List Samsung Electronics Service Manual 7 9 7 8 MP Tray Assembly Exploded Views 0 1 2 3 4 5 ...

Страница 140: ...Block diagram Service Manual 8 2 Samsung Electronics 8 8 8 Block Diagram 8 1 System Block Diagram ...